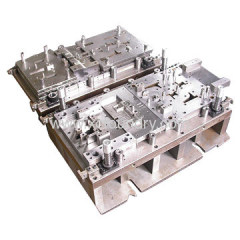

trimming die

1.0~2.0 USD

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 200 sets/month |

| Place of Origin: | Shandong |

Company Profile

| Location: | Qingdao, Shandong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Foundry Machinery Molding Machine, Foundry Machinery And Equipment, Sand Blast Machine, Steel Surface Cleaning, The Core Making Equipments |

Product Detail

| Means of Transport: | Ocean, Air, Land |

|---|---|

| Production Capacity: | 200 sets/month |

| Packing: | yes |

| Delivery Date: | 25 days |

Product Description

trimming die

Mold according to the machining of metals processing classification, commonly used are:

Stamping die, stamping die, bending die, drawing die, flanging die, necking die, the ups and downs of mold, bulging mold, plastic mold;

Forging die, including forging the forging die, upset forging die; and the extrusion die and die-casting mold.

For processing non-metallic and powder metallurgy mold according to the processing object naming and classification of plastic mold, rubber mold and powder metallurgy mold.

2 forging die for the thermal state metal forging mold. Forging, the billet is often After several rounds of deformation can be made from forgings, which requires several cavity carved in a single module. The metal in turn sent to each cavity, and plastic flow in the cavity, and finally filled the cavity made from forgings. In the forging, the billet is difficult to finish forging cavity volume equal to the blank selection is slightly larger in order to avoid waste. To this end, the final forging die around the cavity of the lower die interface has a flash tank to the storage of excess metal, forming the cut edge will fly. Should minimize sharp corners, deep grooves in the cavity, in order to facilitate metal plastic flow and filling, reduce mold wear and cracking, improve die life.

Stamping die, stamping die, bending die, drawing die, flanging die, necking die, the ups and downs of mold, bulging mold, plastic mold;

Forging die, including forging the forging die, upset forging die; and the extrusion die and die-casting mold.

For processing non-metallic and powder metallurgy mold according to the processing object naming and classification of plastic mold, rubber mold and powder metallurgy mold.

2 forging die for the thermal state metal forging mold. Forging, the billet is often After several rounds of deformation can be made from forgings, which requires several cavity carved in a single module. The metal in turn sent to each cavity, and plastic flow in the cavity, and finally filled the cavity made from forgings. In the forging, the billet is difficult to finish forging cavity volume equal to the blank selection is slightly larger in order to avoid waste. To this end, the final forging die around the cavity of the lower die interface has a flash tank to the storage of excess metal, forming the cut edge will fly. Should minimize sharp corners, deep grooves in the cavity, in order to facilitate metal plastic flow and filling, reduce mold wear and cracking, improve die life.