Single Screw Barrel

500.0~600.0 USD

| Min. Order: | 1 Piece/Pieces |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | T/T, WU |

| Supply Ability: | 5000PCS/month |

| Place of Origin: | Jiangsu |

Company Profile

| Location: | China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | 001 |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Plastic Type: | PVC |

| Use: | Waste Plastic Crusher |

| Shaft Design: | Single |

| Brand Name: | dongghao |

| Production Capacity: | 5000PCS/month |

| Packing: | carton |

| Delivery Date: | 10-12days after payment confrimation |

Product Description

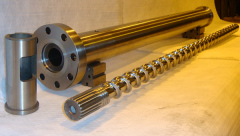

1. Material is 38CrMOALA, tempering hardness: 260-290HBS, Nitridation layer depth: 0.4-0.7,

Nitridation rigidity on surface: 940-1050HV,

Thickness: 2.6-3mm; Hardness: HRC62± 2, without crack and flaw; Make bottom part nitridation treatment;

2. Material is 3Cr2W8V, H13(injection chamber), the whole body quenching hardness: HRC60± 2, nitridation hardness: 1050HV, inner hold for fine grinding Ra value 0.4

3. Material: Cr12molvl, the whole body quenching hardness: HRC60± 2, inner hole for fine grinding Ra value 0.4;

4. Diffluencece combing, backflow parts material: Imported SKD61 quenching hardness: Above HRC55 or double alloy structure;

5. Can proceed to plate hard chrome after nitriding screw surface; The thickness for chromeplate is 0.03-0.04mm;

6. The passagewaypart for all kinds of mould, the thickness for plating hard chrome is 0.05-0.08, Polishing fine-coarse degree reach Ra value 0.4-0.2;

Nitridation rigidity on surface: 940-1050HV,

Thickness: 2.6-3mm; Hardness: HRC62± 2, without crack and flaw; Make bottom part nitridation treatment;

2. Material is 3Cr2W8V, H13(injection chamber), the whole body quenching hardness: HRC60± 2, nitridation hardness: 1050HV, inner hold for fine grinding Ra value 0.4

3. Material: Cr12molvl, the whole body quenching hardness: HRC60± 2, inner hole for fine grinding Ra value 0.4;

4. Diffluencece combing, backflow parts material: Imported SKD61 quenching hardness: Above HRC55 or double alloy structure;

5. Can proceed to plate hard chrome after nitriding screw surface; The thickness for chromeplate is 0.03-0.04mm;

6. The passagewaypart for all kinds of mould, the thickness for plating hard chrome is 0.05-0.08, Polishing fine-coarse degree reach Ra value 0.4-0.2;

.jpg)