PVC pipe plant and Extrusion Machinery

| Min. Order: | 1 Set/Sets |

|---|---|

| Payment Terms: | L/C, T/T |

| Supply Ability: | 60 sets every year |

| Place of Origin: | Shandong |

Company Profile

| Location: | Qingdao, Shandong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Service |

| Main Products: | Plastic Sheet Extrusion Machine, PVC Sheet Extrusion Line, PVC Profile Extruding Machine, PVC Foam Board Extrusion Line, PP Pipe Production Line |

Product Detail

| Model No.: | SJSZ series |

|---|---|

| Means of Transport: | Ocean |

| Plastic Type: | PVC |

| Use: | Others |

| Shaft Design: | Double |

| Brand Name: | shunlida |

| Power: | 60-300Kw |

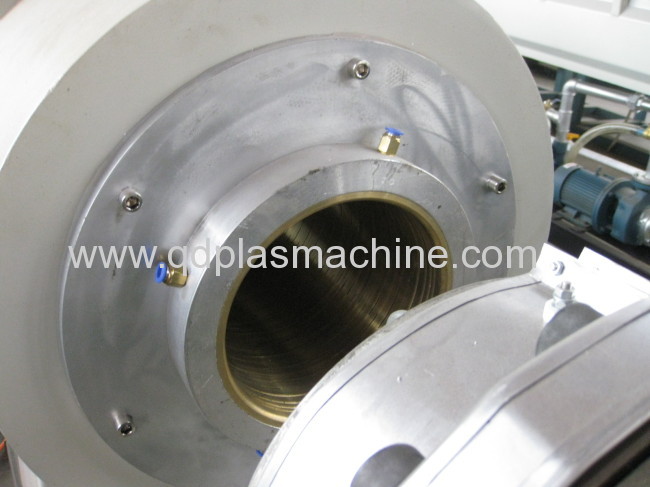

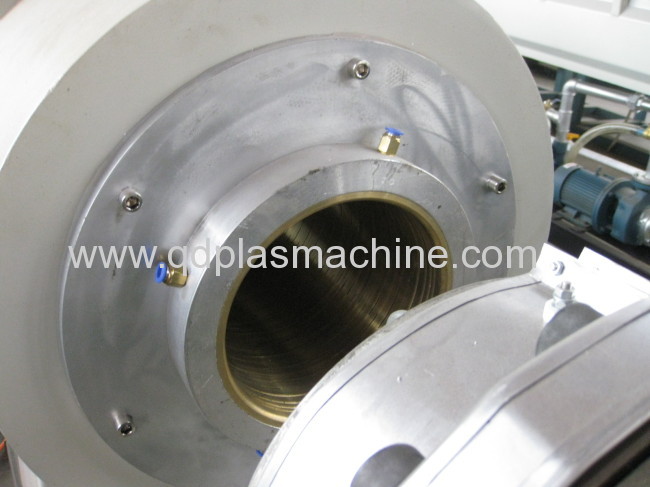

| screw design: | Double-screw |

| Hard chrome plating: | 38CrMoAlA |

| barrel material: | 38CrMoAlA |

| Model number: | SJSZ series |

| Electric motor and pump: | domestic well-known brand |

| capacity: | 150-400kg/h |

| Plastic Processed: | PVC |

| Barrel Heating: | Power saving heaters |

| screw and barrel surface: | Hard chrome plating |

| Gear Box: | Helical/Worm |

| Production Capacity: | 60 sets every year |

| Packing: | plastic film and wooden pallet |

| Delivery Date: | within 45 working days from the deposit |

Product Description

PVC pipe plant and extrusion machinery can be produced out of the conical twin screw extruder .The production capacity can reach to 350kg/h.

Twin Screw Extrusion Line (PVC Pipe plant):

We are the renowned manufacturers of twin screw extrusion line which is extensively used for PVC pipes. Available in different models and technical specifications, it provides high output at low power consumption and is durable, easy to operate and efficient in performance.

Twin Screw Extrusion Line:

We are engaged in the manufacturing of precision engineered twin screw extrusion line that are used in various extrusion processes. The extrusion plant is suitable for laminating the coil paper, unwoven fabric, aluminum foil and many more. The machine is designed, developed and fabricated in compliance with international standards using superior quality material. It is appreciated for high peel off strength, symmetrical thickness and good leak tightness. Further, our range of extrusion line ensures absolutely smooth and trouble free production and can also be customized as per the technical specifications detailed by client.

PVC being a heat sensitive material necessitates a very controlled temperature during processing. Extrusion of PVC is best possible with closely intermeshing twin screw extruder with relatively less power as compared to single screw. twin screw extruders are known for the power optimisation and are offered in the range from 110 kg/hr up to 500 kg/hr.

Features:

- Minimizes energy inputs

- Achieves uniform pumping

- Front barrel with HSS sleeve offered for selected models

- Minimizes wear and tear

- Economic replacement option

- Japanese PID digital temperature controllers

- High accuracy of +/- 1 Degree C

- High reliability

- Hard face coating on selected models

- PLC controls as standard on select models

General applications:

- Supplying portable water for rural and urban places

- Casing and column pipes for bore well

- City sewage pipes

- Domestic plumbing

- Effluent discharge lines

- Electrical conduits

- Sprinkler irrigation system

- Inside housing telecom connections

Twin Screw Extrusion Line (PVC Pipe plant):

We are the renowned manufacturers of twin screw extrusion line which is extensively used for PVC pipes. Available in different models and technical specifications, it provides high output at low power consumption and is durable, easy to operate and efficient in performance.

Twin Screw Extrusion Line:

We are engaged in the manufacturing of precision engineered twin screw extrusion line that are used in various extrusion processes. The extrusion plant is suitable for laminating the coil paper, unwoven fabric, aluminum foil and many more. The machine is designed, developed and fabricated in compliance with international standards using superior quality material. It is appreciated for high peel off strength, symmetrical thickness and good leak tightness. Further, our range of extrusion line ensures absolutely smooth and trouble free production and can also be customized as per the technical specifications detailed by client.

PVC being a heat sensitive material necessitates a very controlled temperature during processing. Extrusion of PVC is best possible with closely intermeshing twin screw extruder with relatively less power as compared to single screw. twin screw extruders are known for the power optimisation and are offered in the range from 110 kg/hr up to 500 kg/hr.

Features:

- Minimizes energy inputs

- Achieves uniform pumping

- Front barrel with HSS sleeve offered for selected models

- Minimizes wear and tear

- Economic replacement option

- Japanese PID digital temperature controllers

- High accuracy of +/- 1 Degree C

- High reliability

- Hard face coating on selected models

- PLC controls as standard on select models

General applications:

- Supplying portable water for rural and urban places

- Casing and column pipes for bore well

- City sewage pipes

- Domestic plumbing

- Effluent discharge lines

- Electrical conduits

- Sprinkler irrigation system

- Inside housing telecom connections

Main technique parameter

Item\Type | SJSZ-160 | SJSZ-250 | SJSZ-400 | SJSZ-630 |

Screw Rotate Speed (r/min) | 15-110 | 10-90 | 8-80 | 8-80 |

Productive tubing scope(mm) | 63-160 | 110-250 | 200-400 | 400-630 |

Main Motor Power (kw) | 22 | 55 | 75 | 125 |

Heating Power(Kw) | 12 | 20 | 35 | 42 |

Max. Extrusion Capacity (kg/h) | 150 | 250 | 350 | 500 |

Vacuum forming length(mm) | 6000 | 6000 | 6000 | 6000 |

Cooling Mode | Air cooling, water cooling | |||

Traction speed(m/min) | 1-16 | 0.4-7 | 0.1-2 | 0.1-2 |

Cutting method | Circular Saw Blade | Annular cutting | Annular cutting | Annular cutting |

Total power(kw) | 85 | 120 | 155 | 200 |

Production line length(m) | 25 | 30 | 35 | 48 |