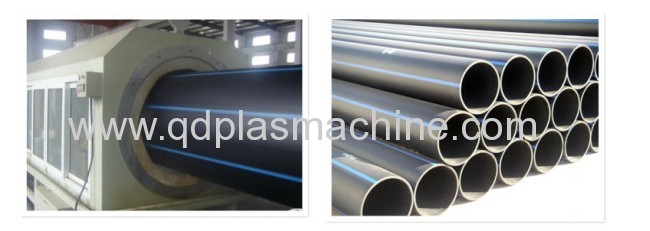

PE PP PP-R plastic pipes extruding machinery

| Min. Order: | 1 Set/Sets |

|---|---|

| Payment Terms: | L/C, T/T, WU |

| Supply Ability: | 60 sets every year |

| Place of Origin: | Shandong |

Company Profile

| Location: | Qingdao, Shandong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Service |

| Main Products: | Plastic Sheet Extrusion Machine, PVC Sheet Extrusion Line, PVC Profile Extruding Machine, PVC Foam Board Extrusion Line, PP Pipe Production Line |

Product Detail

| Model No.: | SJ120/30 |

|---|---|

| Means of Transport: | Ocean, Air |

| Plastic Type: | PP/PE |

| Use: | Others |

| Shaft Design: | Single |

| Brand Name: | shunlida |

| Power: | 130Kw---750Kw |

| pipe diameter range: | 16mm-800mm |

| screw type: | single screw |

| screw material: | 38CrMoAIA |

| Voltage: | 380V |

| application: | water , energy , electricity supply, |

| processing type: | according to CE standard |

| power type: | electricity heating |

| Process: | plastic pipe processing machinery |

| certification: | CE, ISO9001 passed |

| automatic grade: | PLC automatic control |

| Production Capacity: | 60 sets every year |

| Packing: | plastic film and wooden case |

| Delivery Date: | within 45 working days from the deposit |

Product Description

Introduce:

Plastic pipe extrusion line is widely used to produce water pipe, drainage pipe, electric pipe and so on. It contains conical twin screw extruder, mould, calibrating tank, cooling tank, haul-off, cutter and stacker.

Description:

PE PP PP-R PVC series plastic pipe extruding machinery line is mainly used in the area of agricultural water supply system, architectural water supply system, pavement of cables-etc. The unit consists of vacuum calibration tank, haul-off, cutter unit etc mainly . Single screw extruder and haul-off unit have applied imported A/C frequency inverter; Both vacuum pump and driving motor have applied excellent products. The haul-off includes two-claw type, three-claw type, four-claw type, six-claw type, eight-claw type, ten-claw type, twelve-claw type-etc. No-scraps cutting, saw cutting or planetary cutting can be applied, the property of machine group is reliable, the production efficiency is high. With special device, it can produce inner wall spiral pipe, inner wall hollow pipe, and core layer foam pipe-etc. It can also produce PP, PE, ABS, PP-R, PEX, silicon core pipe and pipe of other material. The planetary cutting machine is fully automatic computer digital control; It has such advantages of simple operation.THE MACHINE SET COMPOSITION FEATURES:

1. The optimum spiral structure feeding throat highly improves the output of extruder

2. Accurate temperature control system ensures materials melting performance

3. Unique screw design achieves better plasticizing and high quality products

4. Precisely designed gearbox with a high torsion guarantees stable running

5. "H" shape frame to decrease vibrating of extruder

6. Advanced PLC operation system realizes synchronization and automation

7. Adopt automatic water temperature & level control and special independent filters on both vacuum and cooling tanks

8. Offer stable haul-off unit with 2-12 caterpillars

9. Provide saw & chip-free cutting options

10. Low energy consumption, excellent performance, and easy maintenance.

Manufactured pipes: