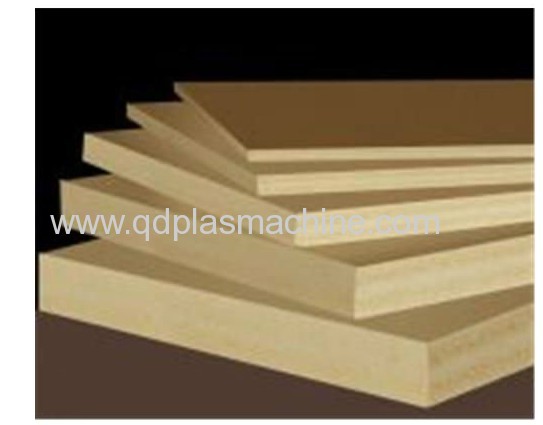

Wood plastic WPC foam board extrusion equipment

| Min. Order: | 1 Set/Sets |

|---|---|

| Payment Terms: | L/C, T/T |

| Supply Ability: | 10 sets every month |

| Place of Origin: | Shandong |

Company Profile

| Location: | Qingdao, Shandong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Service |

| Main Products: | Plastic Sheet Extrusion Machine, PVC Sheet Extrusion Line, PVC Profile Extruding Machine, PVC Foam Board Extrusion Line, PP Pipe Production Line |

Product Detail

| Model No.: | SJSZ80/156,92/188 |

|---|---|

| Means of Transport: | Ocean |

| Plastic Type: | PVC |

| Use: | Others |

| Shaft Design: | Double |

| Brand Name: | shunlida |

| Power: | 160Kw |

| Model Number: | SJSZ80/156 |

| Product type: | plastic board |

| Processing type: | Extruding machine |

| application: | construction ,furniture board |

| Certification: | CE & ISO9001 |

| Main motor power: | 75Kw |

| width of board: | 1220mm |

| thickness of board: | thickness of board |

| capacity: | 150-350kg/h |

| Dimension(L*W*H):: | 28*3*3 |

| Production Capacity: | 10 sets every month |

| Packing: | Export packing, covered with film , wooden crates packing |

| Delivery Date: | within 60 working days after 30% payment |

Product Description

wpc foam board extrusion equipment

1 wood powerder +pvc +chemical additives

2.Board size thicknes 2-18mm with 100-2000mm

3. SJSZ series high-efficiency conical twin screw extrusion equipment specially used for wood plastic panel, with advantages of steady capacity and energy conservation

4. Using international advanced CAD design software, 38CrMoAIA alloy steel with superior quality and coating metal on surface, special mixing material function and high plastify capacity of screw and barrel

6. Cooling system of screw core uses constant temperature system controlled by hot oil, so that material can be plastified well. And barrel uses vacuum exhaust type, so that moisture content can volatilize fully and keep product quality

7. Driving by DC motor with advantages of steady output and large torque, and it also uses ABB or England Eurotherm speeder with the advantages of large extrusion quantity and high-efficiency.

Main composition of Extrusion line:

Item | Description | Quantity |

SJSZ 80/156 Conical twin Screw Extruder | ABB frequency converter, SIEMENS contactor, Japan, Motor power:75KW | one set |

.Calibration unit | calibration plate:1500mm×500mm 4couples | one set |

Cooling tank and bracket | length:6000mm trimming knife:3 sets | one set |

Haul-off unit | 8 couples cylinder clamping and loosening | one set |

Longitudinal cutter | Max. cutting width 1220mm, the cutting width can be adjusted, Cutting motor power3Kw x 2 | one set |

Traverse cutter | Max. cutting width 1500mm,Cutting motor power 3Kw | one set |

Stacker | Stacking method is pneumatica | one set |

Mould (T-Die ) | uitable compression ratio to ensure uniform flow stability. | one set |

Auxiliary equipment | ||

SHRL300/600 mixer | Capacity500~600Kg/h | one set |

500 Grounder | Motor power 37 KW | one set |

360 Plastic Crusher | Motor power 11KW | one set |