WPC hollow decking with groove production line

| Min. Order: | 1 Set/Sets |

|---|---|

| Payment Terms: | L/C, T/T, WU |

| Supply Ability: | 5 set/sets every month |

| Place of Origin: | Shandong |

Company Profile

| Location: | Qingdao, Shandong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Service |

| Main Products: | Plastic Sheet Extrusion Machine, PVC Sheet Extrusion Line, PVC Profile Extruding Machine, PVC Foam Board Extrusion Line, PP Pipe Production Line |

Product Detail

| Model No.: | WPC profiles tiles |

|---|---|

| Means of Transport: | Ocean |

| Plastic Type: | PVC |

| Use: | Others |

| Shaft Design: | Double |

| Brand Name: | shunlida |

| Power: | 120Kw |

| Model Number: | SJSZ-65/132 |

| Max. profile width: | 1200mm |

| Processing type: | Extruding machine |

| Product type: | WPC profile tiles |

| Certification: | CE |

| Main motor power: | 120Kw |

| screw structure: | double-screw |

| Input material: | PVC resin , Calcium Power |

| capacity: | 200kg/h |

| PVC recycling: | crusher, grinding etc. |

| Production Capacity: | 5 set/sets every month |

| Packing: | standard wooden case |

| Delivery Date: | within 60 working days after 30% payment |

Product Description

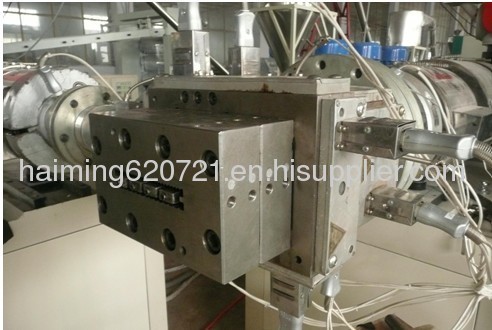

1. wpc hollow decking with groove production line lists

Item | Name | Model | Qty |

1 | SJSZ65-132 | 1Unit | |

2 | Vacuum calibrating platform | ZD-6000 | 1Unit |

3 | Caterpillar haul off | LQ-300 | 1Unit |

4 | Cutting unit | ZQ-300 | 1Unit |

5 | stacker | FZ-6000 | 1Unit |

2. wpc hollow decking with groove production line description

Description | Parameters |

Product size | customized |

Material | PVC powder+ additives |

Production line speed | 0.5-1.5m/min |

Max. output | 150-200kg/h |

Overall dimensions | 25m×2.5m×3m (L×W×H) |

Weight(Approx) | 13T |

Total installed power | 120kw |

Actual energy consumption power | 80kw |

Gas consumption | 0.4m3/min |

Air pressure | 0.6mpa |

Water circulating device | 0.5m3/min |

Electric condition | 380V/3P/50Hz |

Water used for industry, no impurities, by filtrating, water pressure: 0.4mpa water temperature14~25°C | |

Work environment temperature | 0-40°C |

3.Function of WPC decking profile extrusion machine

1) Mainly used to produce the PVC + wood profiles, plastic decorative decking and PVC

foam profiles

2) Use frequency conversion for speed regulation

foam profiles

2) Use frequency conversion for speed regulation

3) Has super-taper twin-screw extruder with temperature controlling instrument in the screw core

4) Saves power by 30% - 40%

5) The rigid gear surface of the reducer can be operated continuously for a long

time without trouble

6) Operation and mold changing are smooth and steady

time without trouble

6) Operation and mold changing are smooth and steady

7) Long usage life