PE PP waste film granulating Line

| Min. Order: | 1 Set/Sets |

|---|---|

| Payment Terms: | L/C, T/T, WU |

| Supply Ability: | 60 set/sets every year |

| Place of Origin: | Shandong |

Company Profile

| Location: | Qingdao, Shandong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Service |

| Main Products: | Plastic Sheet Extrusion Machine, PVC Sheet Extrusion Line, PVC Profile Extruding Machine, PVC Foam Board Extrusion Line, PP Pipe Production Line |

Product Detail

| Model No.: | SJ-100x25 |

|---|---|

| Means of Transport: | Ocean |

| Plastic Type: | PP/PE |

| Use: | Others |

| Shaft Design: | Single |

| Brand Name: | shunlida |

| Power: | 54Kw |

| Material: | waste PE PP |

| Processing machine: | extruding machine |

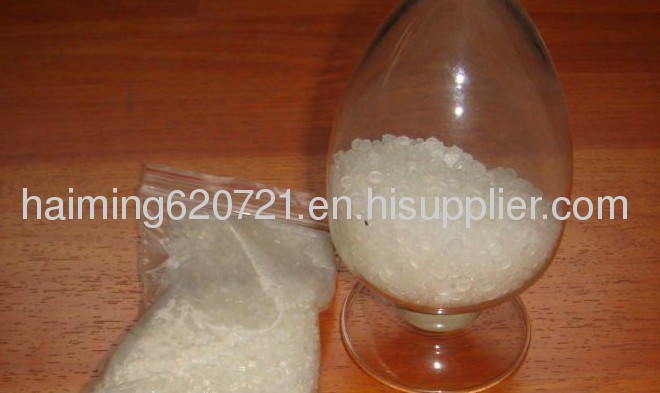

| Product type: | PE granules |

| screw type: | single - screw |

| screw material: | 38CrMoAiA |

| barrel material: | 38CrMoAiA |

| machine total length: | 10m |

| net-changer method: | hydraulic screen changer |

| certification: | CE passed |

| capacity: | 200kg/h |

| Production Capacity: | 60 set/sets every year |

| Packing: | Wood pallet covered by plastic film |

| Delivery Date: | 45 days from the deposit |

Product Description

The PP/PE film pelletizing line used to pelletize the scraps to granules.

The PET pelletizing line used to pelletize the flakes to granules.

Also we offer the pelletizing line to produce the granules by plastic powder, such as PVC, PS.

The pelletizing line also used to color mixing and pelletizing to produce colored granules.

Also the pelletizing line used to produce the modified plastic granules.

The machine you are looking at is for PP/PE film granlating/pelletizing.

Features:

Our products are more reasonable

In design, more excellent in processing and more durable in usage.

This line is consisted with charging system, crushing machine, extruder, granule cutting machine, mould, hydraulic sieve changer, centrifugal dewater machine and air sending system.

Here for the Hydraulic screen changer:

Hydraulic pressure station is designed for extruder quickly changing the screen. It is in small cubage but in high flow. At the same time, it is with low noise, can move and easy to operate.

There are two sieve lift poles in the screen changer. When you need to change the screen, only one lift pole leaves the duct and the other one rests on the duct, let the plastic pass. This special device doesnt need to stop the main motor when you want to change the screen which avoids turn off then on problems in screen changing process.

The PET pelletizing line used to pelletize the flakes to granules.

Also we offer the pelletizing line to produce the granules by plastic powder, such as PVC, PS.

The pelletizing line also used to color mixing and pelletizing to produce colored granules.

Also the pelletizing line used to produce the modified plastic granules.

The machine you are looking at is for PP/PE film granlating/pelletizing.

Features:

Our products are more reasonable

In design, more excellent in processing and more durable in usage.

This line is consisted with charging system, crushing machine, extruder, granule cutting machine, mould, hydraulic sieve changer, centrifugal dewater machine and air sending system.

Here for the Hydraulic screen changer:

Hydraulic pressure station is designed for extruder quickly changing the screen. It is in small cubage but in high flow. At the same time, it is with low noise, can move and easy to operate.

There are two sieve lift poles in the screen changer. When you need to change the screen, only one lift pole leaves the duct and the other one rests on the duct, let the plastic pass. This special device doesnt need to stop the main motor when you want to change the screen which avoids turn off then on problems in screen changing process.

No. | Item |

1 | Charging system |

2 | Crushing machine |

3 | Extruder |

4 | Granule cutting machine |

5 | Mould |

6 | Hydraulic sieve changer |

7 | Centrifugal dewater machine |

8 | Air sending system |

9 | Silo |