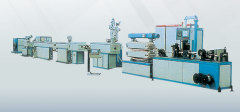

PE PP sheet extrusion production line

| Min. Order: | 1 Set/Sets |

|---|---|

| Payment Terms: | L/C, T/T, WU |

| Supply Ability: | 10 sets every month |

| Place of Origin: | Shandong |

Company Profile

| Location: | Qingdao, Shandong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Service |

| Main Products: | Plastic Sheet Extrusion Machine, PVC Sheet Extrusion Line, PVC Profile Extruding Machine, PVC Foam Board Extrusion Line, PP Pipe Production Line |

Product Detail

| Model No.: | SJ series |

|---|---|

| Means of Transport: | Ocean |

| Plastic Type: | PP/PE |

| Use: | Others |

| Shaft Design: | Single |

| Brand Name: | shunlida |

| Power: | 200Kw |

| Model Number: | SJ150/33 |

| Product type: | plastic sheet |

| Processing type: | Extruding machine |

| PP sheet machine: | PP sheet |

| Certification: | CE |

| Main motor power: | 200Kw |

| screw structure: | single screw |

| material: | PP PE |

| capacity: | 250-350kg/h |

| color: | as the customer request |

| Production Capacity: | 10 sets every month |

| Packing: | Export packing, covered with film , wooden crates packing |

| Delivery Date: | within 50 working days after 30% payment |

Product Description

The prief description of PP PE board / sheet production line :

the specially designed screws ensure high plasification rate ;

special T-type mould ensure the precise control of thickness of the plastic sheet/board;

precise temperature control can precisely control the plasification process & ensure precise thickness and flatness of the products;

the thickness of the sheet/board is precisely adjustable by adjusting the screws and oil pressure wheels;

unattached rool temperature control system can presisely control the temperature of the roll.

the cutting machine can control the length accurately

the winder can automatically adjust the speed and tension and set the width of needed products freely.

the machine equipped with meter counter can set the length of product .

the specially designed screws ensure high plasification rate ;

special T-type mould ensure the precise control of thickness of the plastic sheet/board;

precise temperature control can precisely control the plasification process & ensure precise thickness and flatness of the products;

the thickness of the sheet/board is precisely adjustable by adjusting the screws and oil pressure wheels;

unattached rool temperature control system can presisely control the temperature of the roll.

the cutting machine can control the length accurately

the winder can automatically adjust the speed and tension and set the width of needed products freely.

the machine equipped with meter counter can set the length of product .

Qingdao Shunlida Plastic Machinery Co.,ltd is science and technology knowledge-intensive corporation integrated with research ,development, fabrication ,sales and service .professionally engaged in the manufacture of plastic machines,including plastic pe pp sheet extrusion line ,plastic pipe production line

and plastic profile extrusion machine .

PE PP sheet extrusion machine is used to produce PP PE sheets ,single-layer and multi-layer sheets ,the

width range from 600mm to 1500mm, the thickness of sheets is from 0.5-3mm.

The PE/PP plastic sheet extrusion machine is equippd with vertical three roller calendar, with high performance extruder capacity ,die mould, screen change system ,cooling bracket ,hual off unit ,cutting

unit ,eadge-cutting unit , punching system and splitting system etc. The sheets are widely used in chemical

industry,packaging ,and food industries, gas transportation ,water supply etc.

Main features of PE/PP sheet Extrusion Line:

1).The specially designed screws ensure high plasticization rate.

2).Special T-type die ensure high the precise control of thickness of the plastic sheet/board.

3)The thickness of sheet is precisely adjusted by adjusting the screws and oil pressure wheels.

4).The cutting machine can precisely control the cutting length.

5).The machine equipped with meter counter can set the length of product.

6).This PE sheet production line can be produced with additives to different requirement such as improving intensity,improving toughness ,flame retardant, enbossing ,frosting etc.

7)Adopting electric-magnetic heater which can save 40% to 60% electric energy.

8).Adopting all electric parts is Simens/Omoron/Schneider brands.