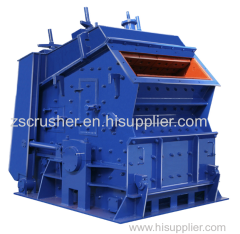

Imapct Crusher

5000.0~50000.0 USD

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, D/P, T/T |

| Supply Ability: | 100 Sets/Month |

| Place of Origin: | Shanghai |

Company Profile

| Location: | China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Model No.: | PF1007/PF1210/PF1315/PF1515 |

|---|---|

| Means of Transport: | Ocean, Land |

| Application: | Others |

| Type: | Crusher |

| Brand Name: | JXM |

| Production Capacity: | 100 Sets/Month |

| Packing: | wooden packing |

| Delivery Date: | 30 days |

Product Description

SpecificationsBest quality impact crusher

1)Excellent reliability;

2)Cubic-shape final products;

3)ISO&SGS certificated;

4)Best services.

1.Certification of impact crusher

•ISO9001:2008 certification

•China Famous Brand

•SGS certification

Application of impact crusher

This series of impact crusher are optimized after adopting advanced techniques. Impact Crusher can crush granite, basalt, bluestone, etc the diameters of which are from 100mm to 500mm, and its crushing compression strength is not more than 320Mp. stone impact crusher features: big reduction ratio, high crushing efficiency, and convenient maintenance. The final product is desirable device for aggregation used in highway and railway surface and water and electricity industry.

features of impact crusher

1.Big output opening,high crushing cavity,suitble in high hardness,big pieses and less power ;

2.The gap in the impact and the hammer plate can be adjusted,efficient control the output feed fineness, the final production has good shape;

3.Tight strucure, good equipment rigidity,big rotational inertia;

4.High hammer plate,big impact resistance and wear resistance.;

Working Principle of impact crusher

impact crusher is the machine which breaks materials using the impact energy. The rotor rotates of our mobile crusher with a high speed driven by power motor when the machine is working. When the materials get into hammer effect area, they are impacting to break with the hammer on the rotor and then threw to the impacting position to take another crushing. After that they spring back to hammer impacting area from impact wrist plate to take crushing again. This procedure repeats itself. The materials get into 1,2,3 impact cavity from big to small to take repeated crushing. When the material is crushed to the required size, it's discharged from the outlet. The material's discharging size and shape can be changed through adjusting the gap between impact frame and rotator.

Model | Rotor speces (mm) | Velovityl (mm) | Feeding Max (mm) | Capacity (t/h) | Power of Motorl (kw) | Overall Dimensions (mm) |

PF1007 | Φ1000×700 | 400×750 | 300 | 37-50 | 30-55 | 2400×1560×2600 |

PF1010 | Φ1000×1050 | 400×1080 | 350 | 55-80 | 55-75 | 2440×2250×2650 |

PF1210 | Φ1250×1050 | 400×1080 | 350 | 60-120 | 110-132 | 2700×2340×2900 |

PF1214 | Φ1250×1400 | 400×1430 | 350 | 130-180 | 132-160 | 2700×2690×2890 |

PF1315 | Φ1300×1500 | 860×1520 | 350 | 150-220 | 180-220 | 3100×3280×2670 |

PF1515 | Φ1550×1500 | 900×1650 | 350 | 200-260 | 260-280 | 3400×3500×3280 |