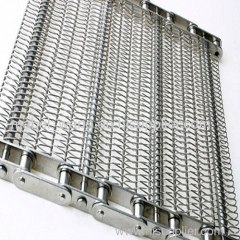

Steel Belt, Drag, and Screw Conveyors

| Min. Order: | 1 Piece/Pieces |

|---|---|

| Payment Terms: | L/C, T/T |

| Supply Ability: | 15 Set/Sets per Month |

| Place of Origin: | Shandong |

Company Profile

| Location: | Yantai, Shandong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Means of Transport: | Ocean |

|---|---|

| Structure: | Conveyor System |

| Material: | Stainless Steel |

| Material Feature: | Oil Resistant |

| Brand Name: | Sanfa |

| Condition: | New |

| Production Capacity: | 15 Set/Sets per Month |

| Packing: | wooden case |

| Delivery Date: | 15 days |

Product Description

1.Compact size, stable operation, low power consumption

2.Discharge chip quantitatively, without overloading.

2.Discharge chip quantitatively, without overloading.

Function

We offers a range of solutions for central chip handling systems based on steel belt, drag, and screw conveyor technology. These provide the ability to handle nearly any chip and coolant situation, transporting chips and coolant to local or central load-out, processing, or filtration systems.

Steel belt conveyors are best suited for low coolant content and bushy or broken chips. Pitch sizes of 2.5" (63mm), 4" (100mm), 6” (150mm), and 9” (225mm) are typically used for chip handling, depending on expected load. Special designs incorporating dimples, perforations, and reinforcements are available to suit more demanding applications.

Drag-link conveyors (also called scraper conveyors) are ideal for fine or broken chiops and greater coolant content Similar pitches to steel belt conveyors are available.

Screw conveyors are best for metering the chip load into processing equipment, and can handle fine or broken chips as well as bundles up to ~12” (300mm). Multiple screws are possible for higher chip loads and larger bundles.

We have a good business relationship with Gleason Works.