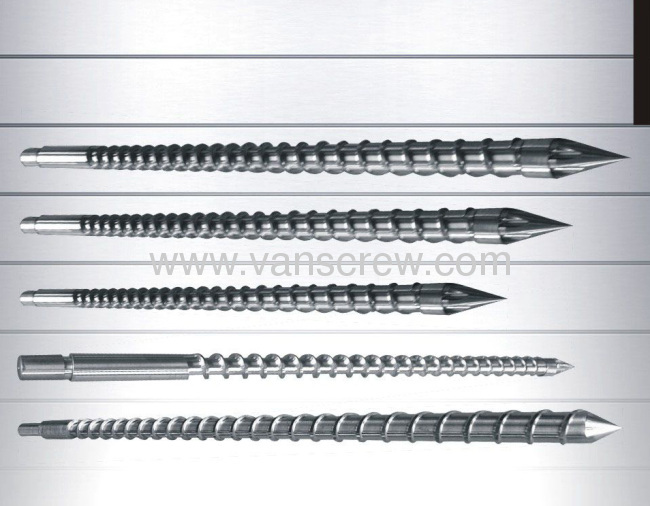

single screw

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 500sets/Month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Zhoushan, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | Screw Barrel, Extrude Single Screw, Parallel Twin Barrel |

Product Detail

| Model No.: | SC-65 |

|---|---|

| Means of Transport: | Ocean, Land |

| Brand Name: | Vanscrew |

| Hardness After Hardening &Tempering: | HB240 -280 |

| Nitrided Hardness: | Hv850-1000 |

| Nitrided Depth: | 0.45-0.7mm |

| Nitrided Brittleness: | ≤Grade 2 |

| Surface Roughness: | Ra0.4 |

| Screw straightness: | 0.015mm |

| Production Capacity: | 500sets/Month |

| Packing: | wooden case |

| Delivery Date: | 30days |

Product Description

Material:

manufactured with high-quality nitro alloy steel, applying the method of hardening and tempering and nitriding, thus it enjoys

Alloy-Steel of High-quality

1)38CrMoALA(JIS SACM645)

2)42CrMo(JIS SCM440)

3)SKD61

Heat-treatment

Nitriding treatment

Electroplated hard-chrome finish

High-frequency quenching

Spray coating Bimetallic-alloy

Vacuum quenching

Technical data

Hardness After Hardening &Tempering: | HB240 -280 |

Nitrided Hardness: | Hv850-1000 |

Nitrided Depth: | 0.45-0.7mm |

Nitrided Brittleness: | ≤Grade 2 |

Surface Roughness: | Ra0.4 |

Screw straightness: | 0.015mm |

Surface Chromate-plating's Hardness After Nitrided: | ≥900Hv |

Chromate-plating Depth: | 0.05-0.10mm |

Bimetallic-alloy Hardness: | HRC56 -65 |

Alloy Depth: | 0.8-2.0mm |

Standards of single screw and cylinder of extruder machine:

Φ20mm~Φ300mm

ratio of length to diameter L/D=15~55