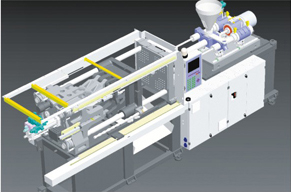

Automatic plastic injection molding machine

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 30sets/month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | GH130-210 |

|---|---|

| Means of Transport: | Ocean |

| Brand Name: | FL |

| Camp force(KN): | 1300-2600 |

| Toggle stroke (mm): | custom made |

| Soace between tie bars(mm): | 500x500 |

| Max.mould hight(mm): | custom made |

| Min.mould height(mm): | custom made |

| Ejector number (pc): | 5 |

| Ejector force (KN): | 61.5 |

| Ejector stroke (mm): | custom made |

| Production Capacity: | 30sets/month |

| Packing: | General Packing |

| Delivery Date: | 40 Days |

Product Description

Precise Horizontal Plastic Injection Mould Machine

Characteristics of Clamping Unit

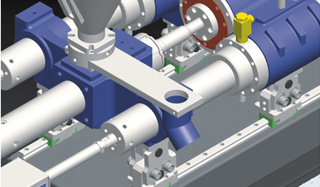

3.1 Optimum designed double-toggle five-joint clamping mechanism has functions such as big force enlarge rate, high-speed and stable movement.

3.2 Having hard chromed on the surface, the pull rods are corrosion-resistant and wear-resistant.

3.3 Using automatic centralized lubrication system.

3.4 The parts of dynamic mould plate and crosshead use lubrication bearing, which has no greasy dirt and can serve even longer.

3.5 Hydraulic eject device with once or multiple eject function.

3.6 With automatic mould-adjust function.

| YH130-210 | ||||

| INJECTION UNIT | ||||

| Sxrew diameter mm | 40 | |||

| Screw stroke mm | 150 | |||

| Screw L:D L/D | 25 | |||

| Shot volume cm3 | 188 | |||

| shot weight Ps g | 170 | |||

| injection pressure Mpa | 144 | |||

| dwell pressure kgf/cm2 | 1466 | |||

| injection speed mm/sec | 300 | |||

| injection rate cm3/sec | 376.8 | |||

| screw rotate speed rpm | 450 | |||

| nozzle sealing force KN | 35.2 | |||

| nozzle advancestroke mm | 80 | |||

| heater power KW | 12.82 | |||

| CLAMPING UNIT | ||||

| clamp force KN | 1300-2100 | |||

| toggle steoke mm | custom made | |||

| space between tie bars mm | 500×500 | |||

| max.mould height mm | custom made | |||

| min.mould height mm | custom made | |||

| ejector number pc | 5 | |||

| ejector force KN | 61.5 | |||

| ejector stroke mm | custom made | |||

| OTHERS | ||||

| specialpump pressure Mpa | 23 | |||

| machine dimensions(L×W×H)m | ||||

| Machine weight T | ||||

| oil tank capacity L | 350 | |||

| pump motor power KW | 22 | |||

The thin-walled products demand, combined with the high-speed thin wall in The thin-walled products demand, combined with the high-speed thin wall injection machine design the development of new technology, the machine series storage stability, its unique injection system, hydraulic system, computer control system, locking system with high strength and wear resistance, fast, so that the properties of high speed, fully meet the requirements for high voltage. The empty short cycle time (2.6 seconds -3.6 seconds) injection of high pressure (up to 240MPA) injection speed (up to 600MM/S), fully qualified for the production of thin-walled products, especially suitable for the production of thin wall (0.4MM) tableware and other containers. jection machine design the development of new technology, the machine series storage stability, its unique injection system, hydraulic system, computer control system, locking system with high strength and wear resistance, fast, so that the properties of high speed, fully meet the requirements for high voltage. The empty short cycle time (2.6 seconds -3.6 seconds) injection of high pressure (up to 240MPA) injection speed (up to 600MM/S), fully qualified for the production of thin-walled products, especially suitable for the production of thin wall (0.4MM) tableware and other containers.

,,,.

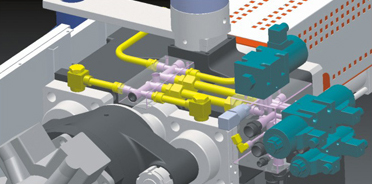

A new circuit of electric control system, multiple sets of proportional control, computer controller dedicated, shorten the whole machine cycle time.5,.

The injection unit accumulator, the basic injection 5 times faster, especially suitable for the production of thin-walled products.

Proportional valve control installation precision mold parts, reduce the template reaction time, improve the production cycle efficiency, and to fine protective effect on mold.

High wear resistance and high lubricity sleeve shaft locking connecting rod structure to ensure the service life.

High rigid locking mold configuration to achieve high speed, high voltage requirements, greatly eliminating all kinds of mechanical deformation, more conducive to prolong the mould life, greatly improved the precision of products

Injection molding machine, injection molding machine or injection machine. It is the main forming equipment plastic products, thermoplastic or thermosetting plastics using plastic molding into various shapes. Divided into vertical, horizontal, all electric. The function of heating plastic injection, high voltage is applied to the molten plastic, so that the injection and full of mold cavity

Welcome to my company contact information