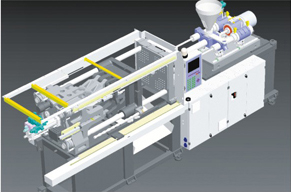

High Speed Injection Mould Machine

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,EXW |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 30sets/month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | GH320 |

|---|---|

| Means of Transport: | Ocean |

| Brand Name: | FL |

| Camp force(KN): | 3200 |

| Toggle stroke (mm): | 700 |

| Soace between tie bars(mm): | 700x700 |

| Max.mould hight(mm): | 750 |

| Min.mould height(mm): | 350 |

| Ejector number (pc): | 5 |

| Ejector force (KN): | 80.4 |

| Ejector stroke (mm): | 180 |

| Production Capacity: | 30sets/month |

| Packing: | General Packing |

| Delivery Date: | 30 Days |

Product Description

High speed Injection Mould Machine

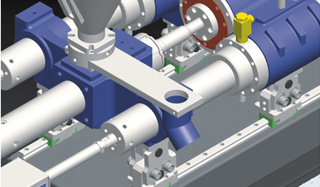

Characteristics of Injection Unit

Optimum designed screw with large L/D ratio enjoys features of wide application, good plasticization and high efficiency.

Oil cylinder base moves on the foundation, the structure is individualistic. The injection device is connected with union stem of front mould plate by ball, regulated easily and reliably.

| GH320 | ||

| INJECTION UNIT | A | B |

| Sxrew diameter mm | 50 | 55 |

| Screw stroke mm | 200 | 250 |

| Screw L:D L/D | 25 | 23 |

| Shot volume cm3 | 393 | 594 |

| shot weight Ps g | 353 | 534 |

| injection pressure Mpa | 164 | 168 |

| dwell pressure kgf/cm2 | 1675 | 1710 |

| injection speed mm/sec | 280 | 230 |

| injection rate cm3/sec | 549.5 | 546.2 |

| screw rotate speed rpm | 400 | |

| nozzle sealing force KN | 46 | |

| nozzle advancestroke mm | 80 | |

| heater power KW | 19.2 | |

| CLAMPING UNIT | ||

| clamp force KN | 3200 | |

| toggle steoke mm | 700 | |

| space between tie bars mm | 700×700 | |

| max.mould height mm | 750 | |

| min.mould height mm | 350 | |

| ejector number pc | 5 | |

| ejector force KN | 80.4 | |

| ejector stroke mm | 180 | |

| OTHERS | ||

| specialpump pressure Mpa | 23 | |

| machine dimensions(L×W×H)m | 7.2×1.8×2.3 | |

| Machine weight T | 16 | |

| oil tank capacity L | 600 | |

| pump motor power KW | 22+18.5 | |

High Speed Injection Mould Machine

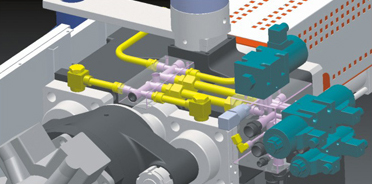

Molding of thin products generally require special mold thin-wall products specially designed. Compared with the conventional products standard mould, die of thin-wall product from the mold structure, gating system, cooling system, exhaust system and release system have undergone significant changes. Mainly in the following areas:

(1) die structure: to withstand molding, thin-wall mould rigidity, strength to higher. So die dynamic, template and its supporting plate weight, thickness is usually higher than the traditional mould template thickness. Support column to, may be arranged in the lock the mold, to ensure accurate positioning and good lateral support, to prevent bending and offset. In addition, high speed injection speed die wear increased, so die using tool steel high hardness, high wear, high erosion areas (such as the gate) hardness should be greater than HRC55.

(2) the gating system: molding of thin products, particularly products thickness is very small, to use a large gate, and the gate should be greater than the thickness of the wall. As is the sprue should set the cold well, in order to reduce the gate stress, help fill, reduce product removal gate damage. In order to ensure a cavity pressure filling thin enough, should as far as possible to reduce the pressure drop in the flow system. Therefore, channel design than the traditional ones, the dwell time at the same time to limit the melt, to prevent resin degradation deterioration. When is a multi cavity mold, balance requirement is far higher than that of conventional requirements of die casting system. Note the thin wall mold gating system is also introduced the two advanced technologies, namely hot runner technology and sequential valve gate (SVG) technology.

Injection molding machine, injection molding machine or injection machine. It is the main forming equipment plastic products, thermoplastic or thermosetting plastics using plastic molding into various shapes. Divided into vertical, horizontal, all electric. The function of heating plastic injection, high voltage is applied to the molten plastic, so that the injection and full of mold cavity

Welcome to my company contact information