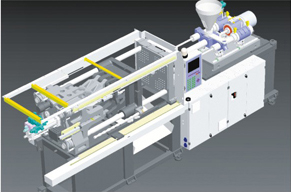

in mould label high speed injection molding machine

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 30sets/month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | GH210 |

|---|---|

| Means of Transport: | Ocean |

| Brand Name: | FL |

| Camp force(KN): | 2100 |

| Toggle stroke (mm): | 490 |

| Soace between tie bars(mm): | 520x520 |

| Max.mould hight(mm): | 550 |

| Min.mould height(mm): | 210 |

| Ejector number (pc): | 5 |

| Ejector force (KN): | 61.5 |

| Ejector stroke (mm): | 150 |

| Production Capacity: | 30sets/month |

| Packing: | General Packing |

| Delivery Date: | 30 Days |

Product Description

IML high speed injection moulding machine

6 sets air blow, high speed injection & clamping, high precision, big toggle stroke, high pump pressure, low pressure mould protection

| GH210 | ||

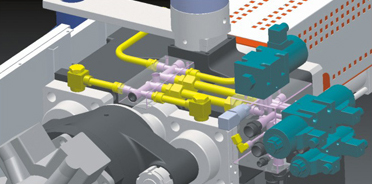

| INJECTION UNIT | A | B |

| Sxrew diameter mm | 45 | 45 |

| Screw stroke mm | 225 | 225 |

| Screw L:D L/D | 25 | 25 |

| Shot volume cm3 | 358 | 358 |

| shot weight Ps g | 322 | 322 |

| injection pressure Mpa | 156 | 157 |

| dwell pressure kgf/cm2 | 1587 | 1599 |

| injection speed mm/sec | 280 | 300 |

| injection rate cm3/sec | 445.1 | 476.9 |

| screw rotate speed rpm | 400 | 400 |

| nozzle sealing force KN | 54.4 | 40.6 |

| nozzle advancestroke mm | 50 | 80 |

| heater power KW | 14.1 | |

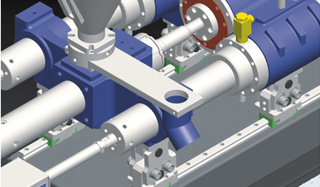

| CLAMPING UNIT | ||

| clamp force KN | 2100 | |

| toggle steoke mm | 490 | |

| space between tie bars mm | 520×520 | |

| max.mould height mm | 550 | 550 |

| min.mould height mm | 210 | 250 |

| ejector number pc | 5 | |

| ejector force KN | 61.5 | |

| ejector stroke mm | 150 | |

| OTHERS | ||

| specialpump pressure Mpa | 21 | 23 |

| machine dimensions(L×W×H)m | 5.64×1.3×1.86 | |

| Machine weight T | 8 | 8.5 |

| oil tank capacity L | 300 | |

| pump motor power KW | 30 | |

PET injection moulding machine

Talking about energy-saving injection molding machine, Li Qiang said: "the injection molding machine adopt servo motor oil electric composite structure, has the advantages of high precision, high response, low noise, excellent energy-saving performance, the actual test, S8 servo energy-saving injection molding machine in the production process, compared with the traditional quantitative pump injection molding machine energy saving energy saving up to 45.5%, the highest 80%."

,,"2012,\,,2012,,,15-50,.,,,\,,,,."

Talk about the effects of nearly two years of economic situation on the injection molding machine industry, Hu Yaqing said, "2012 is a challenge for all of us, but also to reflect on their own, self - improvement opportunity, is a very good chance stable adjustment, in 2012 the company internal training, interior modulation, stable development, many domestic counterparts are decreased by 15-50%, and our company is a few performance growth of enterprise a. Company undivided attention plastic injection molding machine, a brand of domestic a gleam of staff, the Taiwan management, standardized production, procurement standardization, aiming at the market promotion of products, so our company is relatively young, but has been in progress, development speed is very fast."

,,"., ,:,,,,.,.

In addition, according to the market positioning, "the company currently exports. Every year we take part in the domestic and foreign various exhibitions, finally, Li Qiang introduced Ningbo compound machinery recent planning: the main construction machine, and construction machine will be gradually standardized, the constant pursuit of stability requirements, product consistency, appearance consistency. Domestic injection molding machine technology are also constantly improve, mature and stable.

Injection molding machine, injection molding machine or injection machine. It is the main forming equipment plastic products, thermoplastic or thermosetting plastics using plastic molding into various shapes. Divided into vertical, horizontal, all electric. The function of heating plastic injection, high voltage is applied to the molten plastic, so that the injection and full of mold cavity

Welcome to my company contact information