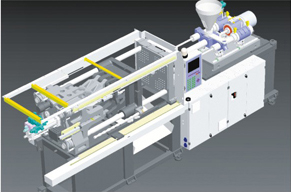

PET special injection molding machinery

| Min. Order: | 1 Set/Sets |

|---|---|

| Payment Terms: | L/C, T/T |

| Supply Ability: | 30sets/month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | GH170 |

|---|---|

| Means of Transport: | Ocean |

| Brand Name: | FL |

| Camp force(KN): | 1700 |

| Toggle stroke (mm): | 435 |

| Soace between tie bars(mm): | 470x470 |

| Max.mould hight(mm): | 500 |

| Min.mould height(mm): | 180 |

| Ejector number (pc): | 5 |

| Ejector force (KN): | 45.2 |

| Ejector stroke (mm): | 130 |

| Production Capacity: | 30sets/month |

| Packing: | General Packing |

| Delivery Date: | 40 Days |

Product Description

PET special injection molding machinery

Power Saving Injection Moulding Machine

High percision clamping.

Low pressure mold protection

Various Models

Well-Experienced Engineers

Timely Delivery

| GH170 | ||

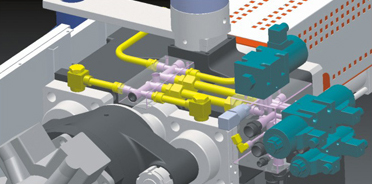

| INJECTION UNIT | A | B |

| Sxrew diameter mm | 40 | 40 |

| Screw stroke mm | 200 | 150 |

| Screw L:D L/D | 25 | 25 |

| Shot volume cm3 | 251 | 188 |

| shot weight Ps g | 226 | 170 |

| injection pressure Mpa | 147 | 156 |

| dwell pressure kgf/cm2 | 1479 | 1584 |

| injection speed mm/sec | 270 | 280 |

| injection rate cm3/sec | 339.1 | 351.7 |

| screw rotate speed rpm | 400 | 400 |

| nozzle sealing force KN | 44.5 | 25.3 |

| nozzle advancestroke mm | 50 | 80 |

| heater power KW | 9.32 | |

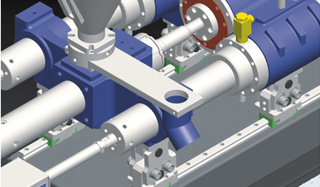

| CLAMPING UNIT | ||

| clamp force KN | 1700 | |

| toggle steoke mm | 435 | |

| space between tie bars mm | 470×470 | |

| max.mould height mm | 500 | 500 |

| min.mould height mm | 180 | |

| ejector number pc | 5 | |

| ejector force KN | 45.2 | |

| ejector stroke mm | 130 | |

| OTHERS | ||

| specialpump pressure Mpa | 21 | 23 |

| machine dimensions(L×W×H)m | 4.5×1.11×1.78 | |

| Machine weight T | 5 | 5.3 |

| oil tank capacity L | 250 | |

| pump motor power KW | 22 | |

PET special injection molding machinery

The filling process and cooling process of conventional injection molding are intertwined, when the polymer melt flow, melt fronts meet the core surface or the cavity wall relative lower temperature, it will form a layer of condensed layer on its surface, the melt flow to continue in the condensate layer, there is a significant effect of the condensing flow layer thickness on the polymer.

\.2.

Need to properties of condensed layers of parenchyma in injection molding for more in-depth research, more comprehensive. Therefore the thin-wall injection molding numerical simulation also need to do a lot of work in the following 2 aspects.

(1),,.,,.,.

(1) a more in-depth and comprehensive study of thin wall injection molding theory, especially the properties of condensed layer, in order to make more reasonable assumptions and boundary conditions. From the above analysis, in thin-wall injection molding process, many of its condition and the conventional injection molding are quite different. Simulation of melt flow mathematical model, many of the assumptions and boundary conditions need to be adjusted in thin-wall injection molding.

(2),.,.,,;,,,;\.,.

(2) to determine the factors that increase in thin-wall injection molding, and properly consider these factors. Some can be ignored in the conventional injection molding factors, tend to have a greater impact on the thin wall molding melt flow. For example, the viscosity in thin-wall injection has obvious dependence on pressure, while in the conventional injection molding is not; weld line strength has great influence on the properties of plastic parts, especially for thin wall plastic parts, welding strength is related to the temperature and pressure, but the conventional numerical simulation without considering the influence of stress; heat capacities, heat transfer coefficient and pressure loss. Commercialization of existing numerical simulation software by ignoring these factors, the prediction of thin wall injection molding filling would appear inconsistent phenomenon.

Injection molding machine, injection molding machine or injection machine. It is the main forming equipment plastic products, thermoplastic or thermosetting plastics using plastic molding into various shapes. Divided into vertical, horizontal, all electric. The function of heating plastic injection, high voltage is applied to the molten plastic, so that the injection and full of mold cavity