Central convey system

| Min. Order: | 1 Set/Sets |

|---|---|

| Payment Terms: | L/C, T/T |

| Supply Ability: | 100sets/month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | SDC- |

|---|---|

| Means of Transport: | Ocean |

| Motor: | 1 |

| Conveying Height(m): | 4.5 |

| Material Hopper Volume(L): | 6 |

| Application: | Powder |

| Production Capacity: | 100sets/month |

| Packing: | General Packing |

| Delivery Date: | 10 Days |

Product Description

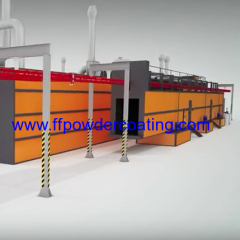

Central convey system

Performance characteristic

Central conveying system enables central processing and closed conveyance of raw materials. Completely eliminates noise,dust and hot air pollution. It is an ideal system to maximize productivity and to irealize dustant centralizde comtrol for one to more sites and increase production efficiency.

Safe production environment & centralized dust removal;

Lower noise;

Decreases energy consumption;

Decreases production cost;

Promotes company image.

Central control unit will be control by PLC that made in foreign.With displays loading, switching on, and alarms for material shortage of every machine via programmed control.

Vacuum valve, small and light, inner rubber fim installed to ensure airtightness, air suction circuit adopted to control closure and opening of air suction pipe.

All sizes of customised s/s hoppers available.

Construction layout

Central convey system

Central convey system

we reserve the right to change specifications without prior notice.