cold forge header machine

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | T/T |

| Supply Ability: | 30sets/ month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | High Speed Cold Forming Machine, Mult-station Cold Forming Machines, Fully Automatic Cold Forming Machines, Bolt Cold Forming Machine, Cold Forming Machine |

Product Detail

| Model No.: | TGH15-50-BP |

|---|---|

| Means of Transport: | Ocean |

| Power: | Cnc |

| Raw Material: | Steel Bar |

| Machine Type: | Roll Forming Machine |

| Extra Services: | Piercing & Punching |

| Automation: | Automatic |

| Certification: | ISO 9001:2000 |

| Material / Metal Processed: | Stainless Steel |

| Brand Name: | Tenggong |

| Color: | According to Customer's Requirement |

| Production Capacity: | 30sets/ month |

| Packing: | depend on buyer |

| Delivery Date: | 30days after deposit |

Product Description

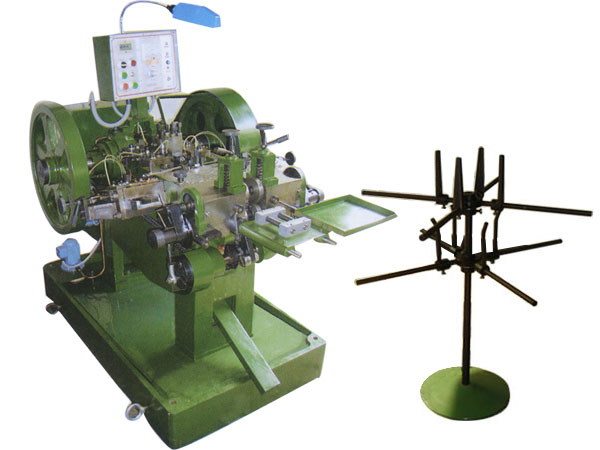

Product Name: cold forge header machine

Model No.: TGH15-50-BP

Cold forge header machine

Specification of high speed Cold forge header machine

Function of high speed Cold forge header machine

Company Advantages:

Ningbo Tenggong Precision Machinery Manufacture Co., Ltd. is subordinated to China Tenglong Stainless Steel Wire Group. In 2010, the company invests in a lot of advanced domestic and international metal plate processing equipments so as to ensure the strategic requirements of high starting point and high quality to the product R & D. We promise favourite prices, best quality and prompt after-sale service.

The machines of our company are accurately made by the current advanced technology in domestic and abroad with priority improvement and assisting the high quality materials, the machines have the advantages of rapid speed, high accuracy, high stability and permanent durability. The machine are suitable for the factories mass producing screws and other hardware and metal products

Model No.: TGH15-50-BP

Cold forge header machine

Specification of high speed Cold forge header machine

| Model no. | TGH15-50-BP |

| Main Motor | 2.25KW (3HP) , 4P, 3PH |

| Voltage | Assigned by client |

| Oil Motor | 0.33KW (1/4HP+12A), 4P, 3PH |

| Main Die | ∮34.5x67.5 |

| 1st Punch Die | ∮31x73 |

| 2nd Punch Die | ∮31x73 |

| Cut-off Die | ∮19x35 |

| Cut Knife | 9x32x64 |

| Wire Diameter | ∮2.3~5.0 |

| Screw Length | 6mm~50mm |

| Production Speed | 150 ~ 170 pcs/min |

| PKO Length | 10mm |

| Machine Weight | approx. 1850 KG |

| Add-on Equipments | Sensor, Conveyor, Light stand |

Function of high speed Cold forge header machine

1. The machine belong to the cold heading machine, the function is the first molding and the second punching products, which is mainly used for forming the heads of the screw products, the work principle is line materials calibration, accessing lines, sending materials to the main mold, first punching initial forging, and second punching the formed blank materials and withdraw. The work gets done without any letup, the production capacity can be up to about 200 every minute, which belongs to the more advanced products in the current technology.

2. Upsetter various materials: Common steel, carbon steel, stainless steel, copper, aluminum, and alloy steel etc with widely functions. (For the stainless steel and alloy steel, can heat them to the appropriate temperature with the heater, and can upsetter.)

3. The machine can make the common products such as the common self-tapping screw, electric screw, micro-screw, socket head cap bolts, self drilling screw, fiber plate screw etc. For an example PKO can upsetter other non standard abnormal hardware and metal products.

Ningbo Tenggong Precision Machinery Manufacture Co., Ltd. is subordinated to China Tenglong Stainless Steel Wire Group. In 2010, the company invests in a lot of advanced domestic and international metal plate processing equipments so as to ensure the strategic requirements of high starting point and high quality to the product R & D. We promise favourite prices, best quality and prompt after-sale service.

The machines of our company are accurately made by the current advanced technology in domestic and abroad with priority improvement and assisting the high quality materials, the machines have the advantages of rapid speed, high accuracy, high stability and permanent durability. The machine are suitable for the factories mass producing screws and other hardware and metal products