neodymium segment magnet epoxy coating

0.02~15.0 USD

| Min. Order: | 10 Piece/Pieces |

|---|---|

| Payment Terms: | L/C, T/T, WU |

| Supply Ability: | 100000pcs/week |

| Place of Origin: | Guangdong |

Company Profile

| Location: | Shenzhen, Guangdong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Distributor/Wholesaler |

| Main Products: | Sintered Ndfeb Magnets N35, Ring Sintered NdFeB Magnet, Disc Neodymium Magnets, Disc Sintered Ndfeb Magnet, Sintered NdFeB Magnet Block |

Product Detail

| Model No.: | SMT-0171S |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Application: | Industrial Magnet |

| Type: | Permanent |

| Composite: | Rare Earth Magnet |

| Brand Name: | Smart |

| Shape: | segment |

| Coating: | Black epoxy |

| Grade: | N30H-N50H, N30SH-N45SH, N28UH-N42UH, N26EH-N38EH, N28AH-N35AH |

| Production Capacity: | 100000pcs/week |

| Packing: | Carton |

| Delivery Date: | 15 days |

Product Description

Neodymium magnet is the strongest magnet in the world till now that can lift up to 1000 times its own weight, it is mainly made of Neodymium, Iron and Boron. It is high remanence, high coercive force, high energy product and high performance/cost ratio. Neodymium magnet is anisotropic and only magnetized in one direction.

Feathers of neodymium segment magnet epoxy coating:

1. Materials: Rare earth Neodymium-Iron-Boron, Sintered NdFeB permanent Magnets;

2. Certification: ISO9001:2000, ISO14001, ISO/TS16949

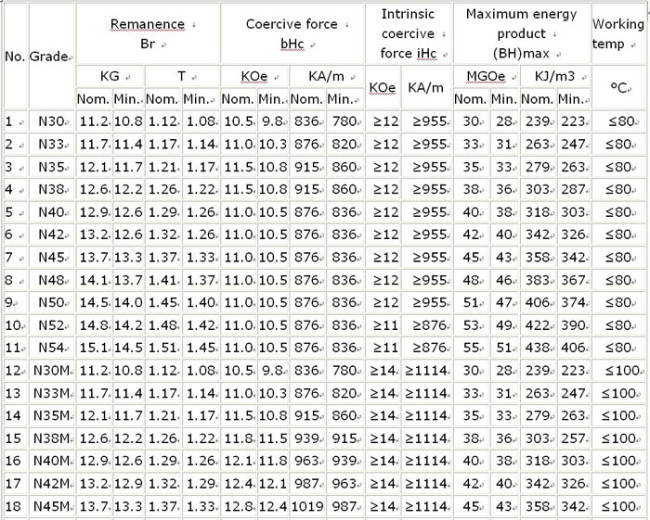

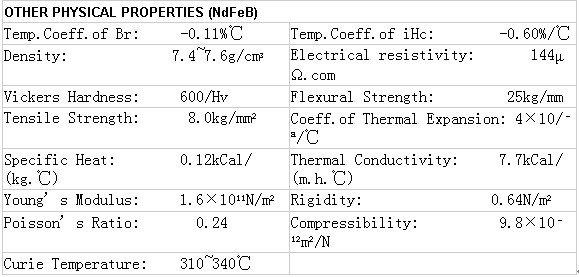

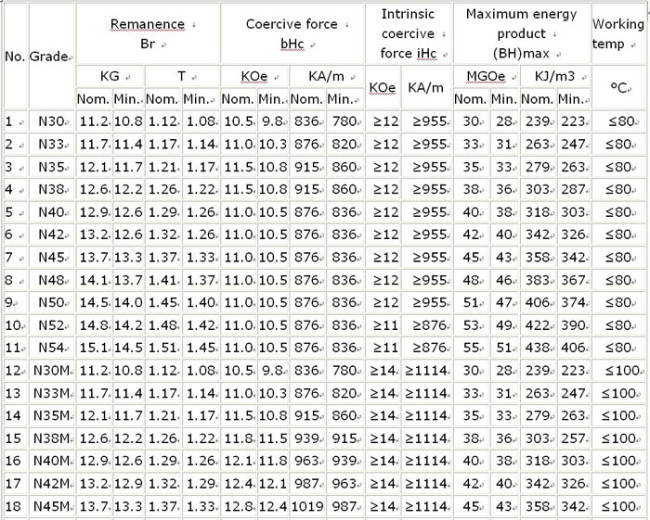

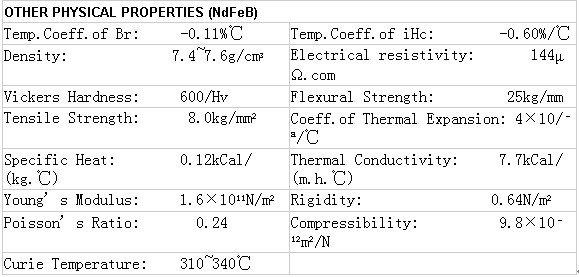

3. Magnetic properties:

a) High coercive force, max is over 35KOe,

b) (BH)max from 28 to 55MGOe,

c) Max working temperature up to 240°C;

4. Grades: N30-N54, N30M-N52M, N30H-N50H, N30SH-N45SH, N28UH-N42UH, N26EH-N38EH, N28AH-N35AH;

5. Shapes: Shapes: segment / tile / arc magnets

Picture of neodymium segment magnet epoxy coating

6. Sizes: OR x IR x H x Degree, Customized;

7. Tolerance of neodymium segment magnet epoxy coating: ±0.05mm, Customized;

Picture of neodymium segment magnet epoxy coating

6. Sizes: OR x IR x H x Degree, Customized;

7. Tolerance of neodymium segment magnet epoxy coating: ±0.05mm, Customized;

8. Coatings: Passivation, Nickel, Zinc, Tin, Aurum, Copper, Epoxy, Chemical, etc.

9. Applications of neodymium segment magnet epoxy coating: Toys, Packing boxes, Micro-special electric machinery, Permanent-magnet instrumental meters, Electronic industry, Nuclear magnetic resonance equipments, Magnetic suspension system, Magnetic transmission gears, Magnet therapy equipment, Sorption, ads, Books managements, Teaching tools, Office automation , Magnetic separators, Copiers, Synchrotrons, Radiation sources, Nuclear industry, Agriculture industrial, Detection earthquake, and so on.

Surface | Coating | Thickness (Microns) | Color | Resistance |

Passivation | 1 | Silver grey | Temporary protection | |

Nickel | Ni+Ni | 10-20 | Silver bright | Excellent to humidity |

Ni+Cu+Ni | ||||

Zinc | Zn | 8-20 | Shining light blue | Good to salt spray |

Cu-Zn | Shining color | Excellent to salt spray | ||

Tin | Ni+Cu+Sn | 15-20 | Silver | Superior to humidity |

Aurum | Ni+Cu+Au | 10-20 | Shining gold | Superior to humidity |

Copper | Ni+Cu | 10-20 | Shining gold color | Temporary treatment |

Epoxy | Ni+Cu+Epoxy | 15-25 | Black, red, grey color | Excellent to climate humidity and salt spray |

Zn+Epoxy | ||||

Chemical | Ni | 10-20 | Silver grey | Excellent to humidity |

Payment Terms:

We accept TT & western union & L/C.

We accept TT & western union & L/C.

Shipping:

1.Terms of Shipment:

By sea, by air, by express courier to the world, Before ordering please contact us to confirm your preferred shipment method.

1.Terms of Shipment:

By sea, by air, by express courier to the world, Before ordering please contact us to confirm your preferred shipment method.

Feedback:

Customer satisfaction is very important to us. If you are satisfied with the items you ordered, please leave feedback. If you are not satisfied with the items you ordered, please contact us before leaving negative feedback. We can work together to resolve any dispute.

Customer satisfaction is very important to us. If you are satisfied with the items you ordered, please leave feedback. If you are not satisfied with the items you ordered, please contact us before leaving negative feedback. We can work together to resolve any dispute.