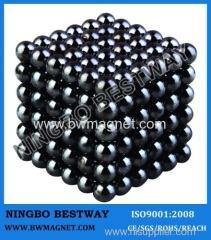

Sintered NdFeB ball magnet

0.05~5.0 USD

| Min. Order: | 10 Piece/Pieces |

|---|---|

| Payment Terms: | L/C, T/T, WU |

| Supply Ability: | 100000pcs/week |

| Place of Origin: | Guangdong |

Company Profile

| Location: | Shenzhen, Guangdong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Distributor/Wholesaler |

| Main Products: | Sintered Ndfeb Magnets N35, Ring Sintered NdFeB Magnet, Disc Neodymium Magnets, Disc Sintered Ndfeb Magnet, Sintered NdFeB Magnet Block |

Product Detail

| Model No.: | SMT-0043S |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Application: | Industrial Magnet |

| Type: | Permanent |

| Composite: | Rare Earth Magnet |

| Brand Name: | Smart |

| Shape: | Sphere |

| Coating: | Nickel |

| Grade: | N35, N38, N40, N42, N45 |

| Production Capacity: | 100000pcs/week |

| Packing: | Carton |

| Delivery Date: | 15 days |

Product Description

Pictures of Sintered NdFeB ball magnet

Description of Sintered NdFeB ball magnet:

1) Rare Earth magnet has superior magnetic properties than other magnets

2) Higher unit magnetic properties

3) Smaller size and lighter weight in designing devices

4) Mostly an iron based alloy, NdFeB type rare earth magnet is much more prone to surface oxidation or rust, and elimination. Users should consider magnet coating,

plating or suitable surface treatment of Sintered NdFeB ball magnet:

5) Less prone to chipping during handling

6) Lower temperature coefficient of magnetic properties than ceramic, higher than SmCo type rare earth magnet

7) Irreversible loss at high temperature

8) Types of Sintered NdFeB ball magnet: N30, N33, N35, N38, N40, N42, N30M, N33M, N35M, N38M, N40M, N27H, N30H, N33H, N35H, N37H, N27SH, N30SH, N33SH, N35SH, N25UH, N28UH, N30UH, N35SH, N38, N45, N48, and N50

9) High energy ranging from 26MGOe to 54MGOe with wonderful coercive force

10) Less expensive, and mechanically stronger and less brittle than SmCo

11) Density: 7.5g/cm2

12) For most applications, coating or plating is recommended

13) Advantages:

a) High energy

b) Very high Hc and Hci output

c) More economical than SmCo

d) Wonderful performance at ambient temperature

14) Disadvantages:

a) Working temperature is below 240oC

b) Prone to oxidation than other magnet alloys

15) Sintered NdFeB ball magnet Widely used in apparatus and instruments where a strong magnetic field is needed, including motors, sensors, microphones, electro-acoustics, magnetic separation,

magnetic suckers and magnetic therapy.

Description of Sintered NdFeB ball magnet:

1) Rare Earth magnet has superior magnetic properties than other magnets

2) Higher unit magnetic properties

3) Smaller size and lighter weight in designing devices

4) Mostly an iron based alloy, NdFeB type rare earth magnet is much more prone to surface oxidation or rust, and elimination. Users should consider magnet coating,

plating or suitable surface treatment of Sintered NdFeB ball magnet:

Type | Information |

Metallic | Zinc, Nickel, Nickel+Nickel, Copper+Nickel, Nickel+Copper+Nickel, Gold, Silver, Tin |

Organic | Epoxy, Nickel+Epoxy coating |

Temporary | Surface Pssivation |

5) Less prone to chipping during handling

6) Lower temperature coefficient of magnetic properties than ceramic, higher than SmCo type rare earth magnet

7) Irreversible loss at high temperature

8) Types of Sintered NdFeB ball magnet: N30, N33, N35, N38, N40, N42, N30M, N33M, N35M, N38M, N40M, N27H, N30H, N33H, N35H, N37H, N27SH, N30SH, N33SH, N35SH, N25UH, N28UH, N30UH, N35SH, N38, N45, N48, and N50

9) High energy ranging from 26MGOe to 54MGOe with wonderful coercive force

10) Less expensive, and mechanically stronger and less brittle than SmCo

11) Density: 7.5g/cm2

12) For most applications, coating or plating is recommended

13) Advantages:

a) High energy

b) Very high Hc and Hci output

c) More economical than SmCo

d) Wonderful performance at ambient temperature

14) Disadvantages:

a) Working temperature is below 240oC

b) Prone to oxidation than other magnet alloys

15) Sintered NdFeB ball magnet Widely used in apparatus and instruments where a strong magnetic field is needed, including motors, sensors, microphones, electro-acoustics, magnetic separation,

magnetic suckers and magnetic therapy.