Quality HDPE heat preservation pipe extrusion line

80000.0~100000.0 USD

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T, WU |

| Supply Ability: | 50 sets per year |

| Place of Origin: | Shandong |

Company Profile

| Location: | Qingdao, Shandong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | PVC Pipe Production Line, PVC Profile Extrusion Line, Parallel Twin Screw Extruder, WPC Profile Extrusion Line, Single Screw Extruder |

Product Detail

| Model No.: | JBD-HDPEG315 |

|---|---|

| Means of Transport: | Ocean |

| Plastic Type: | PP/PE |

| Use: | Others |

| Shaft Design: | Single |

| Brand Name: | JBD |

| Power: | 220kw |

| Capacity: | 350kg/h |

| pipe diameter: | 110-315mm |

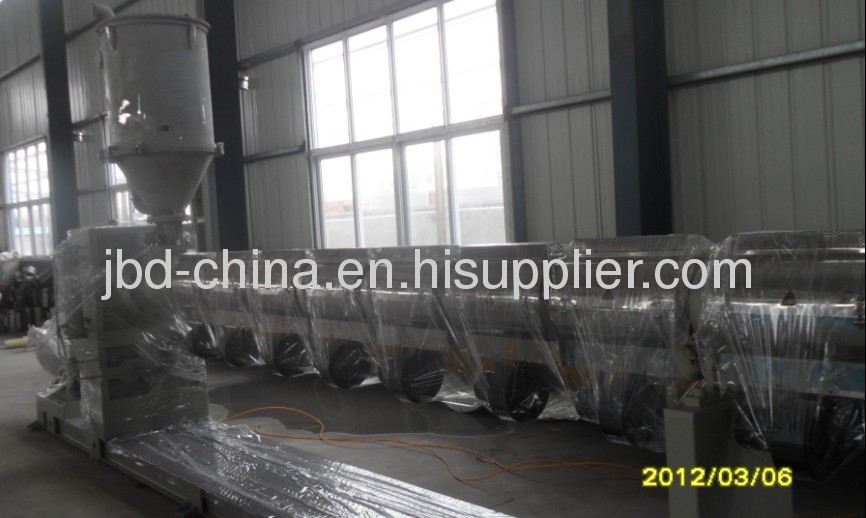

| extruder: | SJ120/33 |

| L/D: | 33:1 |

| Production Capacity: | 50 sets per year |

| Packing: | EPE film or wooden bag |

| Delivery Date: | 40 working days |

Product Description

Quality HDPE heat preservation pipe extrusion line of the pipe with an appropriate degree of rigidity, strength, but also has good flexibility, creep resistance and environmental stress cracking resistance and good hot weld performance, has become a city heating pipes and outdoor pipes give the first choice for large-caliber Products HDPE two-storey, three double-resistant pipe extrusion production line performance and advantages: s latest two-story or three-tier spiral pipe molds for double anti-extrusion, coextrusion layer thickness uniformity, the use of inner and outer double-antibody material (flame retardant, anti-static), the ordinary core HDPE, double-antibody significantly reduced material usage, thereby reducing the cost of dual-resistant tube.

Technique datas

Technique datas

Specification table of one step moulds | |||||||||||||||||||||||||||||||||||||||

|

Photos of each part

1.HDPE heat preservation pipe extruder

2.HDPE heat preservation pipe mold

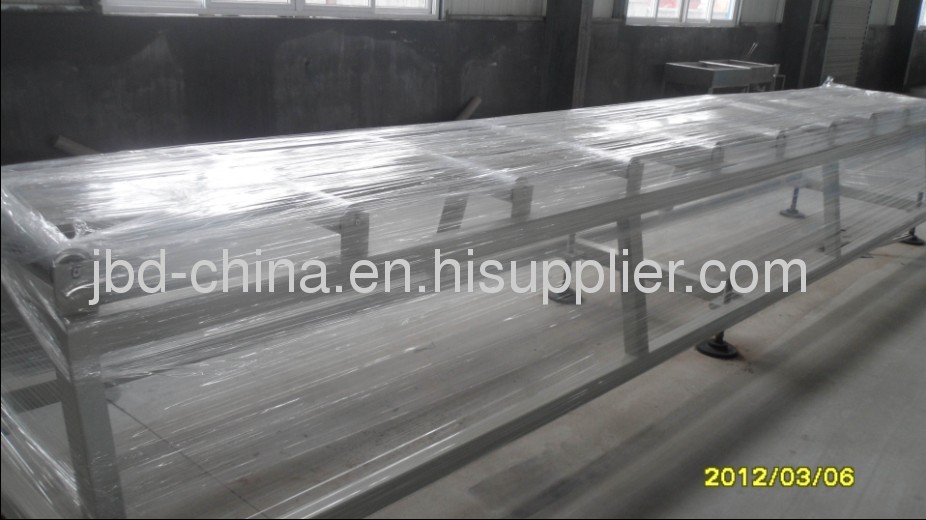

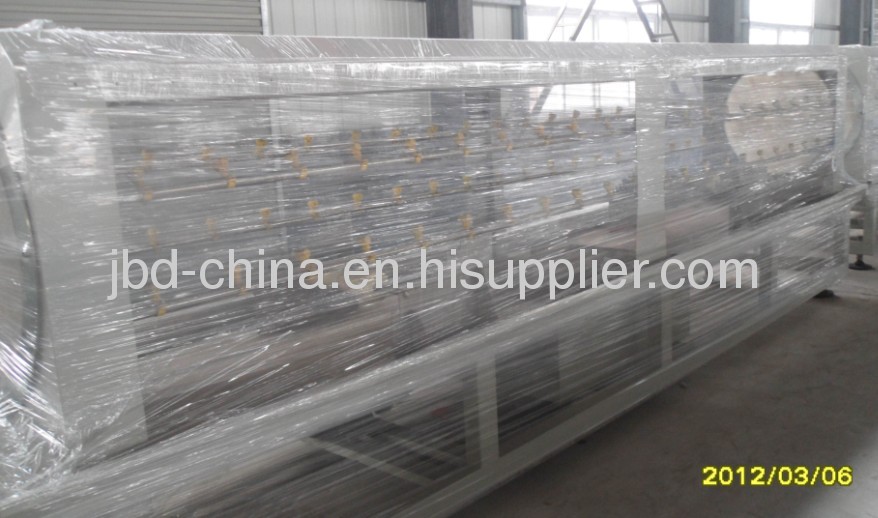

3.HDPE heat preservation pipe vacuum tank

4.HDPE heat preservation pipe spraying tank

5.HDPE heat preservation pipe haul off machine

6.HDPE heat preservation pipe cutting machine

7.HDPE heat preservation pipe stacker