PET sheet line

150000.0~200000.0 USD

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T, WU |

| Supply Ability: | 60 sets per year |

| Place of Origin: | Shandong |

Company Profile

| Location: | Qingdao, Shandong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | PVC Pipe Production Line, PVC Profile Extrusion Line, Parallel Twin Screw Extruder, WPC Profile Extrusion Line, Single Screw Extruder |

Product Detail

| Model No.: | JBD-PET1200 |

|---|---|

| Brand Name: | JBD |

| Power: | 132kw |

| Capacity: | 450kg/h |

| sheet thickness: | 0.2-3mm |

| sheet width: | 600-1200mm |

| Production Capacity: | 60 sets per year |

| Packing: | EPE film or wooden case |

| Delivery Date: | 50 working days |

Product Description

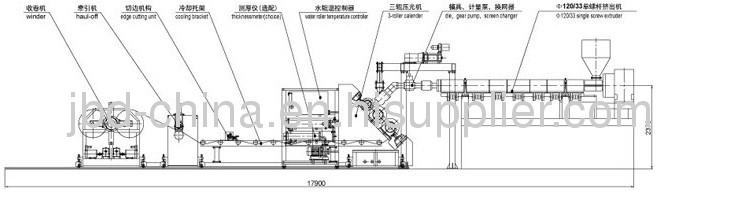

The PET sheet production line manufactured by our company has following technical features:adopting twin screw,high speed meshing type,machine barrel using unique block structure problem that the whole screw and barrel have to be discarded only for partial damage.It decreases repairing cost greatly.The main engine could conbine one,two or several sections vacumm exhausting structure which has strong exhausting capability,which allow fuse-elements pump,stably and well as high precision of frame head mould.PET reclaimed materials can be directly 100% recycled,no crystal drying system is needed,several difficulties that could not be overcome by using mono screw PET were totally solved in this solution.It's pf high best chioce for manufacturers of PET sheet products.The PET sheet extrusion line consists of extruder hydraulic draping,fuss-element pump,mould head and control devices including roller trio plating machine and traction engine etc.All control process are realized through a touch screen panel.

Main technical parameters:

sheet width | 600-2000mm |

sheet thickness | 0.2-2mm |

Max. extrusion capacity | 30-450kg/h |

Production line speed | 15m/min |

Flow of PET sheet making line