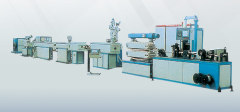

PP/PE double pipe production line

30000.0~50000.0 USD

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T, WU |

| Supply Ability: | 80 sets per year |

| Place of Origin: | Shandong |

Company Profile

| Location: | Qingdao, Shandong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | PVC Pipe Production Line, PVC Profile Extrusion Line, Parallel Twin Screw Extruder, WPC Profile Extrusion Line, Single Screw Extruder |

Product Detail

| Model No.: | JBD-PPSG65 |

|---|---|

| Means of Transport: | Ocean |

| Brand Name: | JBD |

| Power: | 22KW |

| Capacity: | 80-100KG/H |

| Production Capacity: | 80 sets per year |

| Packing: | wooden cases |

| Delivery Date: | 30 working days |

Product Description

PP/PE double pipe production line composes a conical double-screw extruder, different pipe die heads and the relevant auxiliary machines. It is mainly used to produce PP/PE twin pipes which are used as electric drainage pipes and so on. With excellent extruding capacity, the production line can make small diameter pipes of high quality in excellent productivity. PP/PE double pipe extrusion line is easy and safe to operate.

With reasonable structure, stable and reliable performance, PP/PE double pipe making line can fulfill synchronic speed adjustment between the main motor of the extruder and that of the tractor. In addition, by way of vacuum sizing, the sizing effect is getting better and so does the automation of the device.

In the whole line, the vacuum sizing box of the auxiliary equipments consist of two stainless steel sizing boxes actually, which are 5 meters long and can be operated separately. Use automatic controller and motor to control the liquid level and movements respectively. The tractor adopts frequency conversion and the clamping is in a pneumatic way. The cutter is of automatic metering and cutting. Additionally, the stacking bracket can turn automatically.

According to requirements of different clients, the whole production line has desirable man and machine interface which adopts PLC controlling program.

With reasonable structure, stable and reliable performance, PP/PE double pipe making line can fulfill synchronic speed adjustment between the main motor of the extruder and that of the tractor. In addition, by way of vacuum sizing, the sizing effect is getting better and so does the automation of the device.

In the whole line, the vacuum sizing box of the auxiliary equipments consist of two stainless steel sizing boxes actually, which are 5 meters long and can be operated separately. Use automatic controller and motor to control the liquid level and movements respectively. The tractor adopts frequency conversion and the clamping is in a pneumatic way. The cutter is of automatic metering and cutting. Additionally, the stacking bracket can turn automatically.

According to requirements of different clients, the whole production line has desirable man and machine interface which adopts PLC controlling program.

The main technique parameter

Main machine | SJ-65/30 |

Pipe diameter range | φ16-40mm |

Production speed | 12m/min |

Max output | 100kg/h |