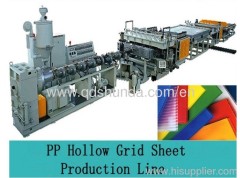

PP hollow sheet production line

100000.0~160000.0 USD

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | T/T, WU |

| Supply Ability: | 50 sets per year |

| Place of Origin: | Shandong |

Company Profile

| Location: | Qingdao, Shandong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | PVC Pipe Production Line, PVC Profile Extrusion Line, Parallel Twin Screw Extruder, WPC Profile Extrusion Line, Single Screw Extruder |

Product Detail

| Model No.: | JBD-PPB1500 |

|---|---|

| Means of Transport: | Ocean |

| Brand Name: | JBD |

| Power: | 150KW |

| Capacity: | 200-300KG/H |

| Board width: | 800-1500mm |

| Board thickness: | 2-12mm |

| Production Capacity: | 50 sets per year |

| Packing: | wooden cases |

| Delivery Date: | 70 working days |

Product Description

PP/PE hollow sheet production line is equiped high performance vented extruder, die, screen change system, vacuum forming table, cooling rocket, haul-off unit, cutting unit and etc.

PP/PE hollow sheet extrusion line is specially designed for producing PC and PP hollow cross-section sheet with width upto 2600mm.

PP hollow cross-section sheet is mainly used in following area:

Construction of sunroof in building, hall, shopping centers, stadiums, public places of entertainment and public facilities;

Rain shed of bus stations, garages, pergolas, corridors;

Transparent shields for security forces in nursery schools, airports, factories;

Skylight of modern agriculture and aquacultures, indoorpools;

Sign boads for ads, light box and exhibition;

Sound insulation board on high way and trestle in city.

PP/PE hollow sheet extrusion line is specially designed for producing PC and PP hollow cross-section sheet with width upto 2600mm.

PP hollow cross-section sheet is mainly used in following area:

Construction of sunroof in building, hall, shopping centers, stadiums, public places of entertainment and public facilities;

Rain shed of bus stations, garages, pergolas, corridors;

Transparent shields for security forces in nursery schools, airports, factories;

Skylight of modern agriculture and aquacultures, indoorpools;

Sign boads for ads, light box and exhibition;

Sound insulation board on high way and trestle in city.

PP/PE hollow sheet production line | |||

MODEL | WIDTH | THICKNESS | OUTPUT |

JBDPP-2100 | 2100MM | 2 -10MM | 250 -350KG /H |

JBDPP-1600 | 1600MM | 2 -10MM | 200 -300KG /H |

JBDPP-1000 | 1000MM | 2 -10MM | 150 -280KG /H |

Photos of PP/PE hollow sheet production line