Superior-quality Rotary Dryer

1000.0~200000.0 USD

| Min. Order: | 1 Set/Sets |

|---|---|

| Payment Terms: | L/C, T/T |

| Supply Ability: | 30 sets/month |

| Place of Origin: | Henan |

Company Profile

| Location: | Zhengzhou, Henan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Ball Mill, Sand Making Machine, Roller Crusher, Magnetic Separator, Jaw Crusher |

Product Detail

| Means of Transport: | Ocean, Land |

|---|---|

| Application: | Others |

| Type: | Others |

| Brand Name: | Zoneding |

| Production Capacity: | 30 sets/month |

| Packing: | Standard Container |

| Delivery Date: | 25-30 days |

Product Description

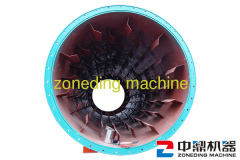

Superior-quality Rotary Dryer

Product Description

Product Description

Zoneding Rotary dryer is widely used in building materials, metallurgy and chemical industry. It is also used to dry slag in cement industry, clay and other materials. The failure frequency is lower because of its simple structure, easy maintenance, low energy consumption and better stability.

The moist material is taken into the tunnel body from the intake end by helical lobes. And then the lifting blade, which has the function of lifting and drying, will lift the material with the help of the rotation of tunnel body. Therefore, tunnel body must be installed with a certain degree of inclination in order to push the material to the lower discharge end. The tunnel body is placed on two jockey pulleys. On the upper jockey pulley, there is a pair of thrust rollers, which is to prevent axial movement of tunnel body while it is rotating. The motor will drive the small gear through speed reducer. The small gear and the big gear on the roller gather in upon each other and work at a uniform speed. The big gear is fixed on the roller, which can make the roller wok.

The moist material is taken into the tunnel body from the intake end by helical lobes. And then the lifting blade, which has the function of lifting and drying, will lift the material with the help of the rotation of tunnel body. Therefore, tunnel body must be installed with a certain degree of inclination in order to push the material to the lower discharge end. The tunnel body is placed on two jockey pulleys. On the upper jockey pulley, there is a pair of thrust rollers, which is to prevent axial movement of tunnel body while it is rotating. The motor will drive the small gear through speed reducer. The small gear and the big gear on the roller gather in upon each other and work at a uniform speed. The big gear is fixed on the roller, which can make the roller wok.

| Specification (m) | Production capacity(t/h) | Main electromotor | Main reduction gear | Weight (t) | ||

| Power (KW) | Type | Type | Speed ratio | |||

| Ø1.2×10m | 2.5 | 7.5 | Y160L-6 | ZL50-16-I | 13.5 | |

| Ø1.5×12m | 3.3-4.9 | 11 | Y180L-6 | JZQ500-III-2F | 18.9 | |

| Ø1.5×15m | 4-6 | 18.5 | Y225M1-6 | JZQ500III2F | 21 | |

| Ø1.8×12m | 4-6 | 11 | Y180L-6 | ZQ50-16II-2 | 16.46 | 22.83 |

| Ø2.2×12m | 7-12 | 18.5 | Y225 M1-6 | JZQ650III | 31.5 | 37.6 |

| Ø2.2×14m | 7-12 | 18.5 | Y225 M1-6 | JZQ650III | 31.5 | 40 |

| Ø2.2×16m | 12 | 30 | Y250M1-6 | JZQ750III | 31.5 | 45 |

| Ø2.4×14m | 12 | 30 | Y250M1-6 | JZQ750-III | 31.5 | 51 |

| Ø2.4×18m | 10-13 | 37 | Y250M2-6 | ZL85-13-I | 27.16 | 54 |

| Ø2.4×20m | 10-14 | 37 | Y250M2-6 | ZL85-13-I | 27.16 | 54.14 |

| Ø3×20m | 25 | 55 | Y280M-6 | ZL100-16-I | 41.52 | 78 |

| Ø3×25m | 32-36 | 55 | Y280M-6 | ZL100-16-I | 41.52 | 104.9 |