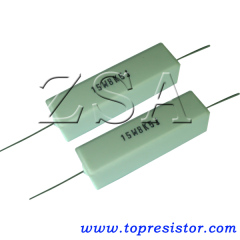

Ceramic Tube Wirewound Resistors

| Min. Order: | 50 Piece/Pieces |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | T/T |

| Supply Ability: | 10000Pieces/Week |

Company Profile

| Location: | Shenzhen, Guangdong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Power Resistor, Load Bank, Aluminum Resistor, Wirewound Resistor, Ceramic Tube Resistor |

Product Detail

| Model No.: | DQR |

|---|---|

| Means of Transport: | Ocean, Air |

| Package Type: | Throught Hole |

| Type: | Fixed Resistor |

| Technology: | Metal Alloy |

| Brand Name: | ZENITHSUN |

| Resistance: | 0.01Ω-100KΩ |

| Resistance Tolerance: | ±0.1%,±0.5%,±1%,±5%,±10% |

| Rated Power: | 15W-20KW |

| Temperature Coefficient: | 300ppm |

| Color: | green |

| Load Rheostat wire: | flat-wise coil |

| Other name: | ceramic wirewound resistor, ceramic tube resistor, high power resistor |

| Operating Temperature: | -80℃-250℃ |

| Mode: | Grid Fixed Or Not Fixed Type |

| Application: | High Power And High Frequency |

| Material: | ceramic tube |

| Mount: | optional |

| Material of wirewound Wire: | Chromium Alloy |

| Solder area: | over 95% |

| Production Capacity: | 10000Pieces/Week |

| Packing: | carton and wooden cases |

| Delivery Date: | 5-7days |

Product Description

Ceramic Tube Wirewound Resistors

Constructions:

1 A tubular ceramic has two terminals, and is wound with copper wire or chrominum alloy wire to provide the resistance and then coated with high temperature, non-flammable resin.

2 After the semi-finished resistor is cool and dry, insulation is appled through a temperature process and then the mounts are attached.

Features:

1 Multi-terminal and multi-resistance, fixed , adjustable are available, out wire's length are available following customer requirement; Special terminals are available for unusual applications.

2 Element consisting of a wave-shaped alloy ribbon or non-wave shaped alloy wire.

3 Good dissipation, high stability, high power rating, high over load and long life.

4 Delivery: 5-7days

5 Conforms to the ROHS standard and the LEAD-FREE non-lead standard.

Applications:

DRseries is suitable for educational modeling applications, load testing, industrial machinery, electric power distribution, instruments, automation control installationa, life trucks, overhead cranes, elevators, arc and spot welders, battery chargers, machine tools, conveyors, and UPS systems.