OEM carbon/alloy steel stamping automotive part by forging

1.0~9.0 USD

| Min. Order: | 1 Ton |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C |

| Supply Ability: | 800 tons/month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Model No.: | JHa12018 |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Brand Name: | Jinhui |

| Material: | Alloy steel, carbon steel |

| Process: | forging |

| Heat Treatment: | Normalize, quench, anneal, temper |

| Surface Treatment: | Rust-prevention, painting, polishing |

| Application: | automotive part |

| Standard: | JIS, DIN, ASTM, BS |

| Production Capacity: | 800 tons/month |

| Packing: | wooden case, hardboard box, iron box |

| Delivery Date: | 5-8weeks |

Product Description

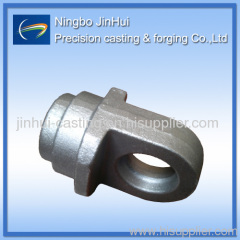

Product name:OEM carbon/alloy steel stamping automotive part by forging

Product Infomation:

1. ModelNO. : JHa12018

2. Weight: 1.5KG

3. Dimension range:12cm*12cm*15cm

4. Tolerance of tough casting: GB/T6414-1999 CT7-9 level

5. Material: carbon steel, alloy steel, stainless steel, etc

6. Field of application: steel stamping automotive part by forging

7. Standard: ASTM, BS, JIN, DIN

8. Design: Customized samples or drawings are accepted

9. Process flow: client drawing - patten - forging - finishing - inspection - packing & delivery

10. Finishing: sand blasting, polishing, plating, acid treatment, anodizing, painting and PVC powder coating

11. Machining:turning, milling, drilling, grinding, threading, CNC machining

12. Quality Control:

1)Machinery properties and Chemical components testing

2)Hardness checking after heat treatment

3)Dimensions testing after maching

If you want know more, please contact us!

OEM carbon/alloy steel stamping automotive part by forging

OEM carbon/alloy steel stamping automotive part by forging

Traid Terms:

1. MOQ: 1ton

2. Payment: L/C, T/T

3. Production lead timeaccording to customer's request

4. Sample can be expressed

5. Package:wooden cases, iron cases or other ways as your requirement

6. Shipping port: Ningbo, Shanghai

Advance & Service:

1. 17 years' casting experience

2. precision investment casting & forging & machining

3. industrial and trading company, more compatitive price

4. over 90% for exporting

5. inquiry will be replied in 24hours

6. professinoal staffs answer your question and solve your problems in fluent English carefully and patiently

7. protect your sales area, ideas of design and all your private information

Company Profile:

JinHui is a professional enterprise with variou kinds steel precision casting, forging and maching. It was founded in 1995, located in Ningbo China. Now there are three companies: Ningbo Jinhui Precision Casting Company, Ningbo Yinzhou Huitai Machinery Fittings Company and Ningbo Huaning Iternational Traiding company.

With high quality working staff, advanced manufacturing and testing equipment and perfect QC system, our products have been sold to North America, East and West Europe, Oceania, the Middle East and East Asia.

| Process | forging |

| Certificate | ISO9001:2000, TS16949, GL/MCC |

| Standard: | JIS, DIN, ASTM, BS |

| Material | Carbon steel, alloy steel, Stainless steel, etc |

| Weight Range | casting: 0.5~80 kgforging:0.1~80Kg |

| Software | AutoCAD,Solid works,Pro/E, etc |

| Heat Treatment | Normalizing, quenching, annealing, tempering |

| Inspection Equipment | magnetic test,radiograph test, ultronic test, presure test, CMM, surface indicator |

| Main Products | machinery part, construction parts,engineering parts, boat part, train & subway part, auto part, etc |

| Max. Capacity | casting: 10000 tons/yearforging: 5000 tons/year |

| Current utilization of capacity | casting 60%, forging 50% |

| Employee | 400 for foundry factory, 60 for forging factory |

| Main Market | Europe,USA,Canada,Australia, etc |

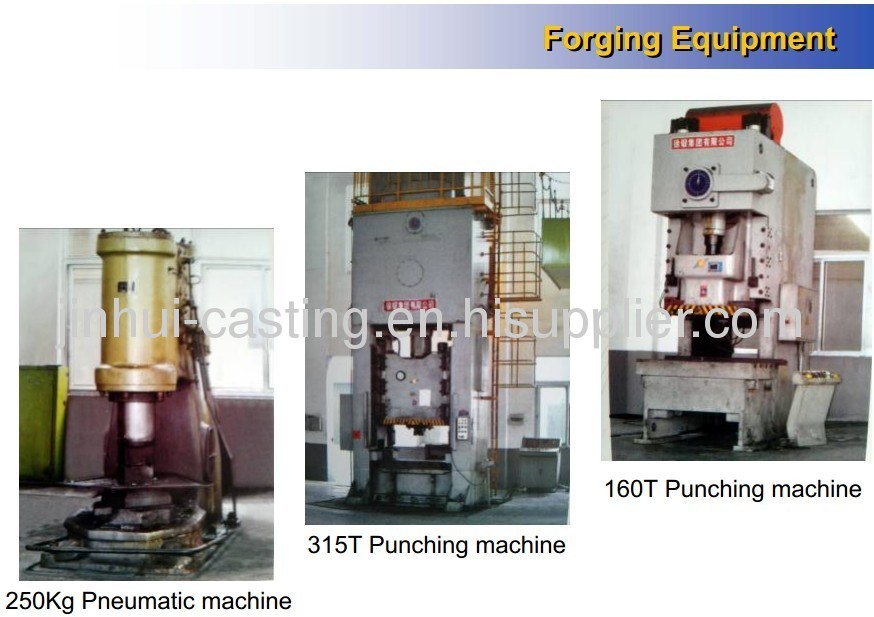

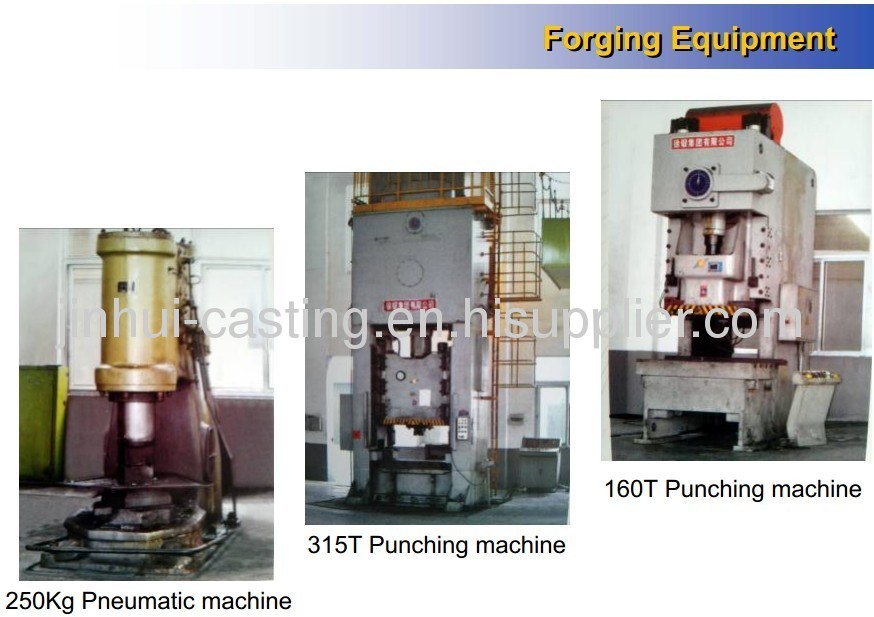

Die forging is a forging process that forging metal in plastic deformation under external force and be full of forging mold. Compared with the free forging, die forging must need a mold to forge. The mold of forging determines the size, shape and quality of products. Therefore, the mold is a very important part in die forging process.

The workpiece is placed into the forge. Then the impact of a hammer causes the heated material, which is very malleable, to conform to the shape of the die and die cavities. Typically only one die is needed to completely form the part. The extra space between the die faces is called the flash. It acts as a relief valve for the extreme pressure produced by the closing of the die halves but is eventually trimmed off of the finished part.