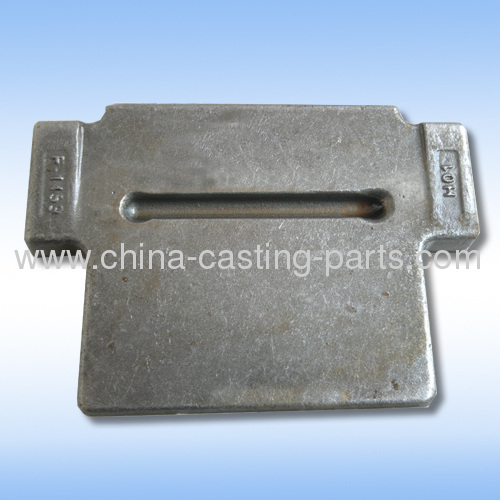

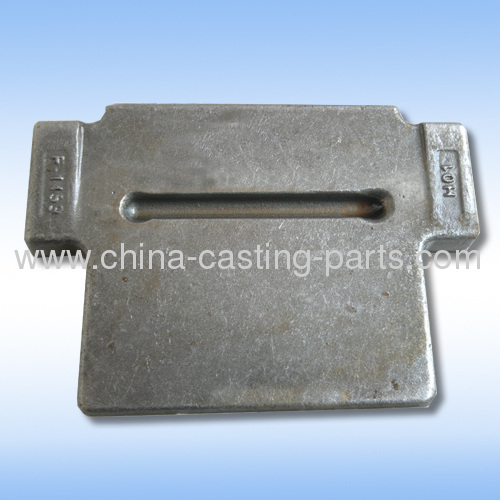

OEM Precision Forging for Train Parts

1.0~12.0 USD

| Min. Order: | 1 Ton |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 1000 tons/month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Model No.: | JH12110 |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Brand Name: | JinHui |

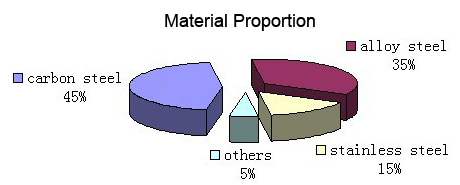

| Material: | carbon / alloy / stainless steel, iron |

| Process: | precision forging |

| Heat Treatment: | normalizing, quenching, annealing, tempering |

| Surface Treatment: | rust-prevention, painting, polishing |

| Standard: | JIS, DIN, ASTM, BS |

| Application: | train parts |

| Production Capacity: | 1000 tons/month |

| Packing: | wooden case, hardboard box, iron box |

| Delivery Date: | 5-8weeks |

Product Description

Product Name: OEM Precision Forging for Train Parts

Item No.: JH12110

Specfications:

1) Process: precision forging.

Item No.: JH12110

Specfications:

1) Process: precision forging.

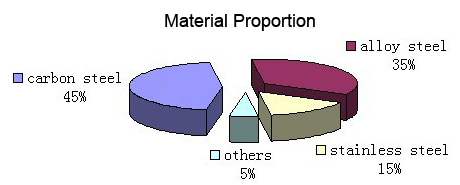

2) Material: carbon steel, alloy steel, stainless steel, iron, etc.

3) Machining: turning, milling, drilling, grinding, threading, CNC machining.

4) Finishing: sand blasting, polishing, plating, acid treatment, anodizing, PVC powder coating, painting...

5) Design: Customized samples or drawings are accepted.

6) Quality System Certificates: ISO9001, TS16949, GL MCC.

7) Weight range: 0.1-30 kg.

OEM Precision Forging for Train Parts

Froging parts-riggings,auto parts,construction parts

1. Materials: carbon / alloy / stainless steel, iron, etc.

2. Various kinds of machining.

3. Very high production rate assure low production cost.

4. Advanced production equipment.

5. Advanced test (inspection) measure.

6. Big production ability.

7. Small quantity also OK.

8. Low price and high quality level.

3) Machining: turning, milling, drilling, grinding, threading, CNC machining.

4) Finishing: sand blasting, polishing, plating, acid treatment, anodizing, PVC powder coating, painting...

5) Design: Customized samples or drawings are accepted.

6) Quality System Certificates: ISO9001, TS16949, GL MCC.

7) Weight range: 0.1-30 kg.

OEM Precision Forging for Train Parts

| JINHUI Forging & Casting Factory Details | |

| Employee | 60 for forging factory, 400 for foundry |

| Established Year | 1995 |

| Process | Precision Forging & Casting |

| Weight Range | 0.1-30 kg for forging, 0.5-80 kg for casting |

| Certificate | ISO9001:2000, TS16949:2009, GL MCC |

| Annual Capacity | 5000 ton for forging, 10000 ton for casting |

Design Software | Pro/E, AutoCAD, Solid Works, etc. |

| Inspection | MT(magnetic test), RT(radiograph test), UT(ultrasonic test), PT(presure test), CMM(Coordinate measuring machine), SI(Surface indicator), HT( hardness test) |

| Export Market / Ratio | Europe, USA, Canada, Austrialia / Over 90% for exporting |

| Main Products | Railway parts, Auto parts, Marine Parts, Investment castings, Forging parts |

Froging parts-riggings,auto parts,construction parts

1. Materials: carbon / alloy / stainless steel, iron, etc.

2. Various kinds of machining.

3. Very high production rate assure low production cost.

4. Advanced production equipment.

5. Advanced test (inspection) measure.

6. Big production ability.

7. Small quantity also OK.

8. Low price and high quality level.

.jpg)

.jpg)