Alloy Steel Forging Auto Parts

1.0~9.0 USD

| Min. Order: | 1 Ton |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | T/T |

| Supply Ability: | 800 tons/month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Model No.: | JH12106 |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Brand Name: | JinHui |

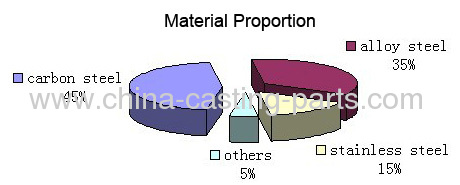

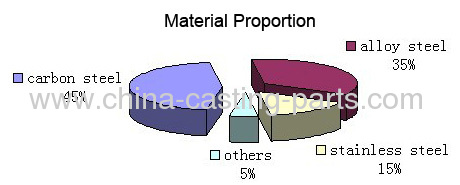

| Material: | carbon / alloy / stainless steel, iron |

| Process: | precision forging |

| Heat Treatment: | normalizing, quenching, annealing, tempering |

| Surface Treatment: | rust-prevention, painting, polishing |

| Standard: | JIS, DIN, ASTM, BS |

| Application: | Auto Parts |

| Production Capacity: | 800 tons/month |

| Packing: | wooden case, hardboard box, iron box |

| Delivery Date: | 5-8weeks |

Product Description

Product Name: Alloy Steel Forging Auto Parts

Item No.: JH12106

Specfications:

1) Process: precision forging.

Item No.: JH12106

Specfications:

1) Process: precision forging.

2) Material: carbon steel, alloy steel, stainless steel, iron, etc.

3) Machining: turning, milling, drilling, grinding, threading, CNC machining.

4) Finishing: sand blasting, polishing, plating, acid treatment, anodizing, PVC powder coating, painting...

5) Design: Customized samples or drawings are accepted.

6) Quality System Certificates: ISO9001, TS16949, GL MCC.

7) Weight range: 0.1-30 kg.

Alloy Steel Forging Auto Parts

We have our own QC team. All products need 3 checked procedure before packing: checking in workshop

(solve timely in case of any problem), professional checking (strictly according to related standard) and re-check before packing (to avoid any possible neglect). All products must be ensured above standards adopted.

3) Machining: turning, milling, drilling, grinding, threading, CNC machining.

4) Finishing: sand blasting, polishing, plating, acid treatment, anodizing, PVC powder coating, painting...

5) Design: Customized samples or drawings are accepted.

6) Quality System Certificates: ISO9001, TS16949, GL MCC.

7) Weight range: 0.1-30 kg.

Alloy Steel Forging Auto Parts

| JINHUI Casting & Forging Factory Details | |

| Employee | 400 for foundry, 60 for forging factory |

| Established Year | 1995 |

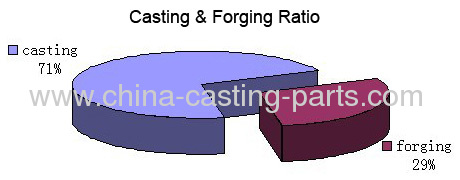

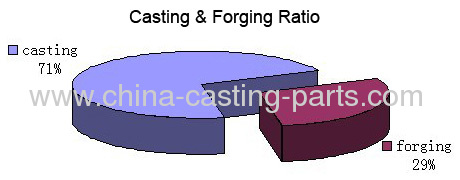

| Process | Precision Investment Casting & Forging |

| Weight Range | 0.5-80 kg for casting, 0.1-30 kg for forging |

| Certificate | ISO9001:2000, TS16949:2009, GL MCC |

| Annual Capacity | 10,000 ton for casting, 5000 ton for forging |

Design Software | Pro/E, AutoCAD, Solid Works, etc. |

| Inspection | MT(magnetic test), RT(radiograph test), UT(ultrasonic test), PT(presure test), CMM(Coordinate measuring machine), SI(Surface indicator), HT( hardness test) |

| Export Market / Ratio | Europe, USA, Canada, Austrialia / Over 90% for exporting |

| Main Products | Railway parts, Auto parts, Marine Parts, Investment castings, Forging parts, MachinedParts, etc. |

We have our own QC team. All products need 3 checked procedure before packing: checking in workshop

(solve timely in case of any problem), professional checking (strictly according to related standard) and re-check before packing (to avoid any possible neglect). All products must be ensured above standards adopted.

High quality, Competitive price, Professional service.

Welcome to contact us for more information!