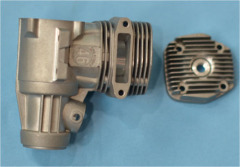

Alloy Steel Lost Wax Casting Part

1.0~9.0 USD

| Min. Order: | 1 Ton |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | T/T |

| Supply Ability: | 800 tons/month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Model No.: | JH12102 |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Brand Name: | JinHui |

| Material: | alloy steel / carbon steel/ stainless steel |

| Process: | lost wax casting |

| Heat Treatment: | normalizing, quenching, annealing, tempering |

| Surface Treatment: | rust-prevention, painting, polishing |

| Standard: | JIS, DIN, ASTM, BS |

| Application: | Rigging Parts |

| Production Capacity: | 800 tons/month |

| Packing: | wooden case, hardboard box, iron box |

| Delivery Date: | 5-8weeks |

Product Description

Product Name: Alloy Steel Lost Wax Casting Part

Model No.: JH12102

Specification:

1) Material: carbon steel, alloy steel, stainless steel, iron, etc.

2) Process: sodium silicate lost wax casting.

3) Machining: turning, milling, drilling, grinding, threading, CNC machining

4) Finishing: sand blasting, polishing, plating, acid treatment, anodizing, painting, PVC powder coating.

5) Design: Customized samples or drawings are accepted.

6) Standard: JIS, DIN, ASTM, BS.

7) Quality System Certificates: ISO 9001, TS 16949, GL MCC.

8) Weight range: 0.5-80 kg.

9) MOQ: 1 ton.

Alloy Steel Lost Wax Casting Part

CUSTOMIZED SAMPLE OR DRAWINGS ARE ACCEPTED,

VARIOUS SIZES AND DESIGNS ARE AVAILABLE,

Model No.: JH12102

Specification:

1) Material: carbon steel, alloy steel, stainless steel, iron, etc.

2) Process: sodium silicate lost wax casting.

3) Machining: turning, milling, drilling, grinding, threading, CNC machining

4) Finishing: sand blasting, polishing, plating, acid treatment, anodizing, painting, PVC powder coating.

5) Design: Customized samples or drawings are accepted.

6) Standard: JIS, DIN, ASTM, BS.

7) Quality System Certificates: ISO 9001, TS 16949, GL MCC.

8) Weight range: 0.5-80 kg.

9) MOQ: 1 ton.

Alloy Steel Lost Wax Casting Part

CUSTOMIZED SAMPLE OR DRAWINGS ARE ACCEPTED,

VARIOUS SIZES AND DESIGNS ARE AVAILABLE,

Product has been presented above, want more similar products, please click the product.

Our product is good in quality and competitive in price. We manufacture casting and supply OEM, ODM service according to your requirement.

If you want more detailed information of this product or related problems, please contact with us, we will reply as soon as possible (general in 24 hours).

| JINHUI Precision Casting & Forging Factory Details | |

| Employee | 400 for foundry, 60 for forging factory |

| Established Year | 1995 |

| Process | Precision Investment Casting & Forging |

| Weight Range | 0.5-80 kg for casting, 1-50 kg for forging |

| Certificate | ISO9001, TS16949, Germanischer Lloyd MCC |

| Annual Capacity | 10,000 ton for casting, 5000 ton for forging |

Design Software | Pro/E, AutoCAD, Solid works |

| Machining | Tuning, Milling ,drilling,grinding, CNC machining |

| Inspection | MT(magnetic test),RT(radiograph test),UT(Ultronic test),PT(presure test), CMM(Coordinate measuring machine),SI(Surface indicator) |

| Main Products | Railway parts, Auto.parts, Marine Parts, Investment castings, Forging parts, Machined Parts, etc. |

.jpg)

.jpg)