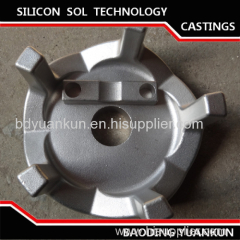

Alloy Steel Castings Parts

1.0~9.0 USD

| Min. Order: | 1 Ton |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | T/T |

| Supply Ability: | 800 tons/month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Model No.: | JH12101 |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Brand Name: | JinHui |

| Material: | alloy steel / carbon steel/ stainless steel |

| Process: | lost wax casting |

| Heat Treatment: | normalizing, quenching, annealing, tempering |

| Surface Treatment: | rust-prevention, painting, polishing |

| Standard: | JIS, DIN, ASTM, BS |

| Application: | Machinery Parts |

| Production Capacity: | 800 tons/month |

| Packing: | wooden case, hardboard box, iron box |

| Delivery Date: | 5-8weeks |

Product Description

Product Name: Alloy Steel Castings Parts

Model No.: JH12101

Specification:

1) Material: Stainless steel / Carbon steel / Alloy steel etc.

2) Process: Sodium Silicate lost wax precision casting+blasting+machining.

3) Machining: turning, milling, drilling, grinding, threading, CNC machining etc.

4) Finishing: sand blasting, polishing, plating, acid treatment, anodizing, painting and PVC powder coating e

5) Design: Customized samples or drawings are accepted.

6) Standard: JIS, DIN, ASTM, BS

7) Quality ystem certificates: ISO 9001:2000, TS 16949:2009, Germanischer Lloyd MCC

8) Weight range: 0.5-80 kg

9) MOQ: 1 ton

Alloy Steel Castings Parts

Model No.: JH12101

Specification:

1) Material: Stainless steel / Carbon steel / Alloy steel etc.

2) Process: Sodium Silicate lost wax precision casting+blasting+machining.

3) Machining: turning, milling, drilling, grinding, threading, CNC machining etc.

4) Finishing: sand blasting, polishing, plating, acid treatment, anodizing, painting and PVC powder coating e

5) Design: Customized samples or drawings are accepted.

6) Standard: JIS, DIN, ASTM, BS

7) Quality ystem certificates: ISO 9001:2000, TS 16949:2009, Germanischer Lloyd MCC

8) Weight range: 0.5-80 kg

9) MOQ: 1 ton

Alloy Steel Castings Parts

Investment casting also called "lost-wax process" offers a wide range of materials from

non-ferrous alloys to tool steel and stainless alloys. This process permits intricate design that

other processes could not produce in other way due to the complexity of their form and shape.

When investment casting, the "near net-shape" is properly applied, it will reduce the total

production cost of your products on the one hand.

On the other hand, it will strengthen the competitiveness of your products with better surface

On the other hand, it will strengthen the competitiveness of your products with better surface

finishes and lighter weights, thinner walls, complicated internal configuration and closer

tolerance. We can manufacture high quality castings, machined or un-machined, conforming

to international standards and make exactly as per your requirements, drawings and tolerances and in wide choice of metal specifications.

| JINHUI Casting & Forging Factory Details | |

| Employee | 400 for foundry, 60 for forging factory |

| Established Year | 1995 |

| Process | Precision Investment Casting & Forging |

| Weight Range | 0.5-80 kg for casting, 1-50 kg for forging |

| Certificate | ISO9001:2000, TS16949:2009, Germanischer Lloyd MCC |

| Annual Capacity | 10,000 ton for casting, 5000 ton for forging |

Design Software | Pro/E, AutoCAD, Solid Works |

| Inspection | MT(magnetic test), RT(radiograph test), UT(ultrasonic test), PT(presure test), CMM(Coordinate measuring machine), SI(Surface indicator), HT( hardness test) |

| Export Market / Ratio | Europe, USA, Canada, Austrialia / Over 90% for exporting |

| Main Products | Railway parts, Auto parts, Marine Parts, Investment castings, Forging parts, MachinedParts, etc. |

JINHUI PRECISION CASTING & FORGING CO. LTD has been mainly specialized in the production of carbon steel, stainless steel, alloy steel precision casting, precision forging and machining for over 17 years in East China.

With high quality working staff, advanced manufacturing and testing equipment and perfect QC system, our products have been sold to North America, East and West Europe, Oceania, the Middle East and East Asia, and are widely used in the industries of auto, train, engineering, construction, chemical, metallurgy, and boat machinery.

High quality, competitive price, good servise.

Welcome to contact us for more information!