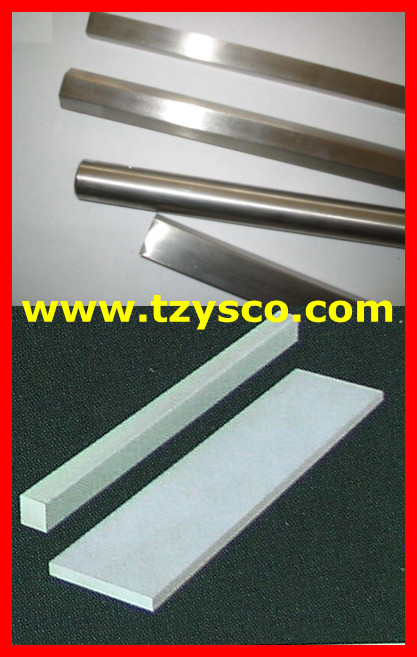

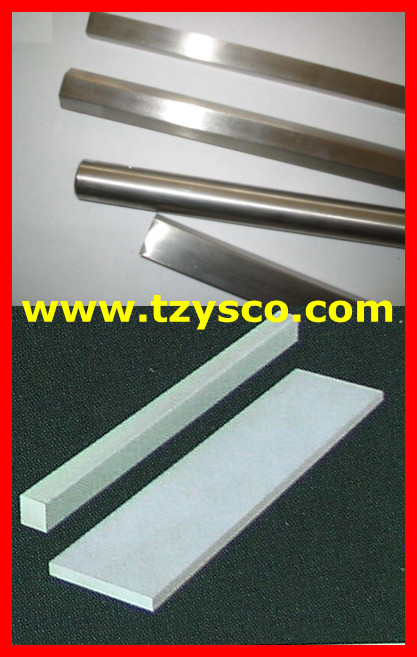

![[304/316/304L/316L] Stainless Steel Flat Bar [hl/ba/No.1] IN STOCK](http://img.hisupplier.com/var/userImages/2012-05/08/150632911_304_316_304L_316L_Stainless_Steel_Flat_Bar_hl_ba_No_1_IN_STOCK_240.jpg)

[304/316/304L/316L] Stainless Steel Flat Bar [hl/ba/No.1] IN STOCK

| Min. Order: | 1 Metric Ton |

|---|---|

| Payment Terms: | L/C, T/T |

| Supply Ability: | 5000 MT/M |

| Place of Origin: | Shanghai |

Company Profile

| Location: | Tianjin, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Agent |

| Main Products: | Stainless Steel Sheet, Stainless Steel Sheets 202, Stainless Steel Sheets 316, Stainless Steel Sheets 304, Stainless Steel Sheet 430 |

Product Detail

| Model No.: | Stainless Steel Flat Bar |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Commodity:: | Stainless Steel Flat Bar |

| Brand:: | TISCO/BAOSTEEL |

| Standard:: | ASTM, AISI, IS, DIN, EN, UNS, CNS, BS, KS, etc |

| Finish:: | 2B,Ba,HL,4K,6K,8K,Mirror,No.1,No.2,No.4,No.5,Wire Drawing |

| Unit Price:: | Negotiation |

| Productivity:: | 5000 metric tons per month |

| MOQ:: | 1 ton |

| Composition:: | High quality steel |

| Applications:: | Mineral,Metallurgy,Chemical,Petroleum |

| Export Markets:: | All over the world |

| Production Capacity: | 5000 MT/M |

| Packing: | Standard seaworthy package,or as customers' requirements |

| Delivery Date: | About 7-15 days after we have got the deposit |

Product Description

[304/316/304L/316L] Stainless Steel Flat Bar [hl/ba/No.1] IN STOCK

Stainless Steel Flat Bar, is a hot rolled stainless shape .Stainless Steel Flat Bar is ideal for all applications where greater strength and superior corrosion resistance is required.Stainless Steel Flat Bar has a durable dull, grainy mill finish and is widely used for all types of fabrication projects that are exposed to the elements.

· Typical Chemical Compositions (SUS 304):

· Typical Mechanical Properties (SUS 304):

· Typical Chemical Compositions (SUS 316):

· Typical Mechanical Properties (SUS 316):

Sheared Flat Bar, not too long ago, was referred to as "sheared and gauered bar". In 1946 Walter Gauer invented a process for removing the razor sharp edges that the shearing process created. Today the more common term used for the process is "edge conditioned". Below is a standard tolerance chart for sheared and edge conditioned material.

General Properties :

· Specifications : JIS SUS 303, SUS304, SUS304L, SUS316, SUS316L

· Typical Chemical Compositions (SUS 304):

o Cr: 18.0% Max

o Ni: 8.0% Max

· Typical Mechanical Properties (SUS 304):

o Ultimate Tensile Strength: 620 N/mm2

o Hardness: 88 Rockwell Ball

o 0.2% Proof Stress: 280 N/mm2

· Typical Chemical Compositions (SUS 316):

o Cr: 17.0% Max

o Ni: 11.0%

o Mo: 2.0%

· Typical Mechanical Properties (SUS 316):

o Ultimate Tensile Strength: 605 N/mm2

o Hardness: 95 Rockwell Ball

o 0.2% Proof Stress: 290 N/mm2

Extruded Flat Bar is drawn through a pre-formed die. To draw, is to "pull through or into". The edges of drawn flats and square bars are closer to a true 90 degree angle and are sometimes referred to as " true bar". Production in this manner allows for tighter tolerances to be maintained. These bars are standard mill products of 10ft to 12ft random lengths and come in a wide variety of grades, sizes and alloys.

Sheared Flat Bar, not too long ago, was referred to as "sheared and gauered bar". In 1946 Walter Gauer invented a process for removing the razor sharp edges that the shearing process created. Today the more common term used for the process is "edge conditioned". Below is a standard tolerance chart for sheared and edge conditioned material.