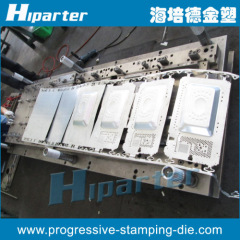

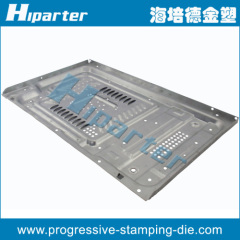

Oven back plate stamping die custom household appliance stamping mold / mould

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,CIF,DAT |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 200 sets per year |

| Place of Origin: | Shandong |

Company Profile

| Location: | Qingdao, Shandong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Model No.: | HPD-Y220 |

|---|---|

| Product: | Household Appliance |

| Product Material: | Metal |

| Brand Name: | hiparter |

| Die type: | progressive stamping die |

| Die material: | SKD11,D2,D3,ASP-23 |

| Die use: | home appliance ,automotive parts |

| Mould life: | 1,000,000 shots |

| Production Capacity: | 200 sets per year |

| Packing: | based on customer's needs |

| Delivery Date: | 50days after payment |

Product Description

Hiparter has rich experience in manufacturing stamping dies, press stamping mold. Almost all the stamping dies of sheet metal parts are built in Hiparter, including Top Plate, Oven Cover, Front control Plate, Side Panel, Brackets etc

Stamping die information

Die type | stamping die for deep drawing ,progressive tool, press stamping die,stage die ect | ||

Die material | ASP-23, SKH-9, SKH51, SKD11,D2, | ||

Acceptable drawing format | .pdf, .dwg, .dxf, .igs, .step, .stp, .x_t... | ||

Stages of Die | 5 | ||

Die Life | 500,000-1,000,000 shots | ||

Die use | home appliance (automotive parts, household metal parts, mobile phone electric metal parts) | ||

Part material | cold steel, galvanized steel, stainless steel, | ||

Machinery Equipment | Milling, Grinding, Boring, CNC, EDM, WEDM, Forming Machine, Precision flat milling, Saw machine, Punching machine, | ||

Die punches | MISUMI, PUNCH, FIBRO, DAYTON, DMEand so on | ||

Inspection Machinery | CMM, Vision Projector, Micro-callipers, Altimeter, Depth Gauge | ||

Lead time | 6 weeks for die buidling, after the die structure drawing confirmed | ||

Die precision | high precision machining, minimum 0.02mm | ||

Trial out press | 15~800T | ||

Delivery | By sea or air,By air around 2-5 days. By sea around 10-30 days. | ||

Certification ISO9001:2008 | ISO9001:2008 | ||

FAQ

Q: What design software do your engineers use?

A: Solidworks, PRO/E, UG, Autocad. Also we are able to work with Caita, Solidworks for format transition. .igs, .step, .x_t, .pdf, .dwg, .dxf files are okay for us.

Q: In general, what's the lead time for the auto car part stamping tool and automotive press tooling?

A: In general, it will cost about 25-45 days to make the first tool trial.

Q: Where is your company located in? Is the traffic convenient?

A: Our company is located in Qingdao, north of China. Our factory is near Liuting International Airport and the Qingdao Port, very convenient for transportation.

Q: What precision measurement machine does Hiparter have?

A: Coordinate measurement machine,vision projector measurement machine,CMM, height gauge etc..

Q: How the quality is controlled?

A: ISO9001:2008 certified by SGS, our QC department will inspection every parts and every stages