China Supplier of High quality Progression Stamping Die

| Min. Order: | 5 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 1100sets/year |

Company Profile

| Location: | Qingdao, Shandong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

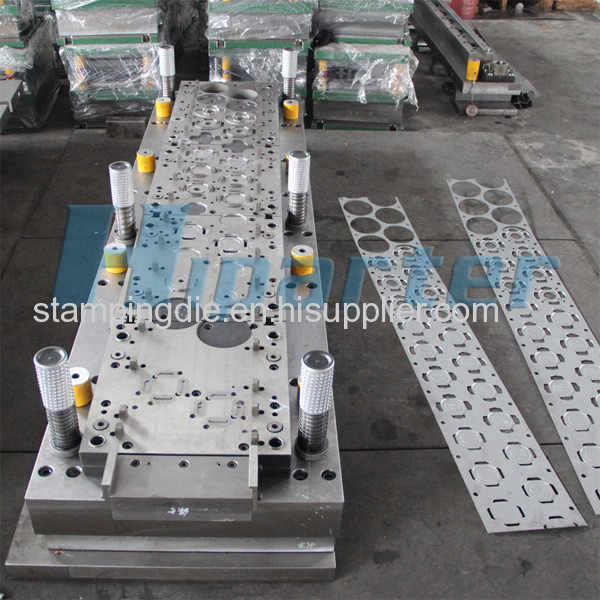

| Model No.: | HPD-T0132 |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Product: | Vehicle Mould |

| Product Material: | Metal |

| Shaping Mode: | Punching Mold |

| Brand Name: | Hiparter |

| Die type: | progressive die |

| Tolerance: | 0.1 |

| Standard Part: | MISUMI |

| Thickness: | 1.2mm |

| Material: | Cold sheet |

| Die material: | SKD11, SKH-9, Cr12mov |

| Die shots: | 500k |

| Production Capacity: | 1100sets/year |

| Packing: | wooden case |

| Delivery Date: | 30 days after die drawing confirmed |

Product Description

China Supplier of High quality Progression Stamping Die, 11 years experience

Product Description

Here shows a progressive strip of dx51d material run on our progressive die;

*ISO9001: 2008 certificated factory.

*we make stamping die especially progressive die for sheet metal parts applied in automotive, appliance, electronics, furniture and electrical industries.

*In-House Tool Making: Use wire EDM machinery & CNC machining centers to construct die components.

*Die steel: SKD11 or D2;

*Stamping Material: Cold rolled steel, galvanized steel, copper, aluminium, stainless steel;

*Press capabilities up to 250 tons with a 2700mm bed.

*Precision measuring instruments: 3D CMM, durometer meter, projector, altimeter and microscope, etc.

*Short Lead Time

*Exporting to: USA, Canada, Finland, France, Italy, Netherlands, Belgium, Greece, Japan, Russia, Jordan, etc.

| Product Name | progressive dies, transfer dies, station dies, drawing dies ,punching dies |

| Die steel | AISI D2/JIS SKD11/ Din1.2379, ASP-23, SKH-9,etc. |

| Stamping Material Type | Carbon steel, hot-dipped galvanized steel, SECC, stainless steel, aluminum, brass, copper, plastic, rubber, FPC(flexible printed circuit) etc. |

| Stamping Material Thickness | 0.1mm-12mm |

| Measuring Instruments | 3D CMM, Hardness Meter, Projector, Digital Height , Microscope ,etc. |

| Equipment | CNC Machining Center, Sodick EDM, Fine Precision Grinding Machine , 40T to 600T Press Machines, etc. |

| Design Software | PRO/E, Auto CAD, Solid Work , UG , Master CAM, Auto form |

| Applications | Automotive (bracket, chassis system, seating and door system,cooling system); Home Appliances (washing machine, freezer, air conditioners ,DVD players); Telecommunication (Antenna base, brackets, enclosures ); In-office equipments like computers, copiers and printers, etc. |

Our features

Die Rapid Development System

Engineering department furnished with the advanced CAD/CAM/CAE software, has all means from the conceptual design for products, reverse engineering, rapid prototype manufacturing, rapid tools to batch production, can supply with a total solution from the development of new products to molds manufacturing for all customers.

All native files and IGS, DXF, STEP, STL, etc. files can be received.

Cost Control

Design Cost, Purchasing Cost, Production Cost, Sales Cost, After Sales Cost ........

Concern the Cost of every step or the cost of the total flow

To optimize the total flow cost

Competitive Lead Time

1- The rapid development system of integrated products and moulds.

2- Integrated Information System for Production

3- One-ticket Responsibility for Parallel Operation

Our Services

Product design

Product reverse engineering

RP/RT Maker(SLA/FDM/CNC for Prototyping)

Product Design Optimization

Die design, building,

Series production

Company Information

Hiparter Dies&Moulds has established itself as a leader in the industry by providing tool expertise from small parts to Class A finishes. We have the capability to design and build automotive, home appliance, truck, construction, agricultural, and lawn and garden tool from small line dies to very large transfer and progressive dies.

Hiparter is known for its highly skilled craftsmen and their ability to work with the customer through all stages of a project, from the design to the building of metal stamping dies. The entire facility is computer networked with a state-of-the-art CAD department transposing customer data of many forms into articulate designs.

We have the tryout press capability to match our customer's needs. Computerized die simulation facilitates the tryout process. Capability studies are conducted to ensure that the customer's quality standards are met.

FAQ

1) Q: What design software do your engineers use?

A: Solidworks, PRO/E, UG, Autocad. Also we are able to work with Caita, Solidworks for format transition. igs, .step, .x_t, .pdf, .dwg, .dxf files are okay for us.

2) Q: How many shots die life is?

A: According to customers' request, we will choose suitable die material, die life is no less than 300,000~1,000,000 shots.

3) Q: How many members in your company?

A: 220 members

4) Q: How is the working time?

A: 8hs/day,12hours per day for CNC, EDM department,6days/week (2 shift).

5) Q: are you able to import and export?

A: Yes. We have our own international trade department. Via our logistics system,we can guarantee the dies and parts arrive at your place on time.