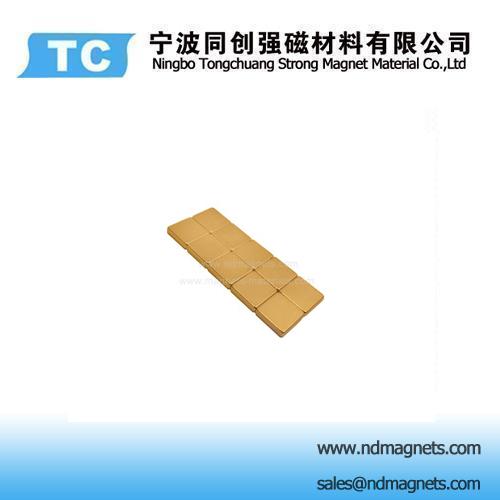

Gold Coating permanent Magnet

0.02~100.0 USD

| Min. Order: | 1 Piece/Pieces |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | T/T |

| Supply Ability: | 1800Tons/Year |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Magnet Arc, Industrial Magnets, Car Magnets, Customer Design Magnets, NdFeB Magnets |

Product Detail

| Model No.: | ND-BLOCK 016 |

|---|---|

| Means of Transport: | Ocean, express, Air, Land |

| Application: | Industrial Magnet |

| Shape: | Block |

| Type: | Permanent |

| Composite: | Rare Earth Magnet |

| Brand Name: | Tong Chuang Magnet |

| Certificate: | ISO9001/2000 .SGS,TS16949 |

| Export Area: | All the world |

| Surface treatment: | Gold coating |

| Magnet grade: | N42,N35 |

| Country of origin: | Ningbo,China |

| Magnetic direction: | by thickness |

| Production Capacity: | 1800Tons/Year |

| Packing: | Carton,Pallet |

| Delivery Date: | Basically 15-17days |

Product Description

Product name: Gold Coating permanent Magnet

Model No.ND-BLOCK 016

Model No.ND-BLOCK 016

Gold Coating permanent Magnets

Property of this Magnet

Material:NdFeB Rare earth

Magnets grade :Grade N35,N38,N42 etc

Magnets size : Bespoke sizes.

Magnets size : Bespoke sizes.

Magnetic direction by thickness

Surface treatment: Gold coating

Max working Temp: 80°C.

The most important point is that we can design the size and shape according your requests, all our magnets are bespoke, due to that we are the original factory. And there is no limit of minimum order quantity.

INTRODUCTION OF NDFEB COATINGS

| Surface | Coating | Thickness Um | Color | SST hours | PCT hours |

| Nickel | Ni | 10-20 | Bright | >24-72 | >48 |

| Ni+Cu+Ni | |||||

| Black Nickel | Ni+Cu+Ni | 10-20 | Bright black | >48-96 | >48 |

| Cr3+Zinc | Zn | 5-8 | Bright Blue | >16-48 | |

| Czn | Color | >24-72 | |||

| Tin | Ni+Cu+Ni+Sn | 10-25 | Sliver | >36-72 | >48 |

| Gold | Ni+Cu+Ni+Au | 10-15 | Sliver | >12 | >48 |

| Ag | Ni+Cu+Ni+Ag | 10-15 | Sliver | >12 | >48 |

| Epoxy | Epoxy | 10-25 | Black,Grey | >48 | |

| Ni+Cu+Epoxy | 15-30 | >48-96 | |||

| Zn+Epoxy | 15-25 | >48-96 | |||

| Passivation | 1-3 | Dark Grey | |||

| Phosphated | 1-3 | Dark Grey | |||

Note:

Salt Spray Test(SST):

Test condition: 5%NaCl, 35℃, Continuously spray a certain time, test whether there is corrosion on coating surface.

3.Pressure Cooking Test(PCT):

Test conditions : 2 atm, 95% RH(relative humidity), 121 ℃

Purpose: Test the coating adhesion.

Notes: The products coating Zinc,passivation/phosphated, or coating Epoxy are not suitable for PCT.

4.Other methods to test the coating quality: Drop test, Cross Cut test,Heating and Spilling Test ,the constant temperature and humidity test etc.

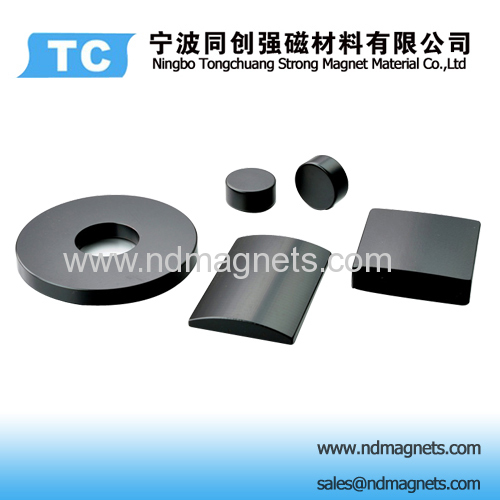

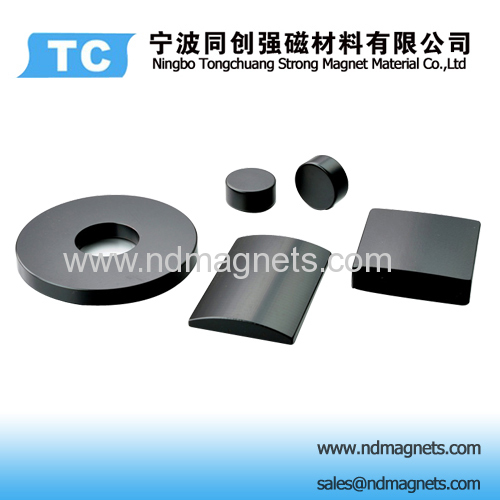

Nickel Coating Neodymium magnets

Gold Coating Neodymium magnets

Epoxy Coating Neodymium magnets

Gold Coating Neodymium magnets

Epoxy Coating Neodymium magnets

Please try to specify the following details while inquirying

1. Magnet size and shape, any sketch is preferable.

2.Magnet grades suitable for your application

3. surface treatment of the magnets: NiCuNi, Epoxy, Zinc, Passivation, ...

4. Order quantity

5. working temperature

6. magnetized direction

7. others which may help us to quote.

For more informations ,please visit our website or consult our engineer.

.jpg)

Our advantages: 1. Original neodymium magnet maker with professional technical and servers.

2. Strict quality control systems under certification TS16949 and ISO 9001

3. Latest facilities to support R&D, quality control, process control, final product inspection

4. Very low prices due to our production well controlled , process optimization,

5, Fast delivery

6. Motto: partnership with all customers

6. Motto: partnership with all customers