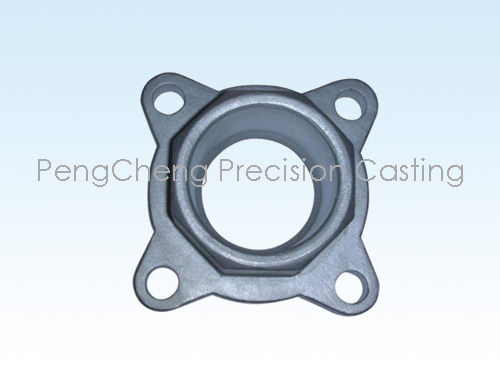

Forging Part

5.0~50.0 USD

| Min. Order: | 50 Piece/Pieces |

|---|---|

| Payment Terms: | T/T |

| Supply Ability: | as per customers |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Investment Casting Parts, Construction Casting, Casting Machining, Carbon Steel Forging, Carbon Steel Castings |

Product Detail

| Model No.: | F004 |

|---|---|

| Means of Transport: | by sea / by air |

| Brand Name: | Forging |

| Specification: | carbon steel stainless steel |

| Function: | valve housings, oil industry |

| Patent Rights: | None |

| Certificate: | ISO9001 & TUV |

| Export Area: | USA CANADA EUROPE |

| Cooperative Company: | Many |

| Production Capacity: | as per customers |

| Packing: | crates |

| Delivery Date: | 60- 90 days |

Product Description

Precision Casting OEM manufacturer high pressure valve housings oilfield tool parts downhole drilling tool parts Ningbo Shanghai. export license ISO9001:2000 TUV (PED 97/23/EC & AD2000 – W0/TRD 100) exporter castings forgings CNC machined parts electrical frequency furnaces air hammer punch friction press oil-hydraulic press CNC lathes CNC machine center milling spectrometer Coordinate Measuring Machine (CMM) Surface Roughness Tester tensile yield hardness low temperature impact PT inspection X-ray hydraulic pressure test CAD Pro-E Solid works Photoshop Adobe carbon steel stainless steel WCC WCB WC6 WC9 LCC CF8 CF8M alloy steel gray iron GGG50 GGG60 GG40 grinding drilling milling.

Pengcheng can provide you qualified forging parts after machining. We began our purchase of raw forging parts since four years ago and the annual quantity is more than 1000tons. We are experienced and keeping well cooperation with many noted enterprises all over the world.

The complete equipments of our cooperative forging factories can fabricate your forged parts most efficiently and effectively. The sustaining development of our machining workshop is the strong guarantee of machining service. We are able to provide facilities of turning, milling, laser cutting, punching, extrusion, molding and others for different machining requests.

Processes: Open die forging; Closed die forging; Flat die forging

Main equipments: 3tons air hammer; 1600tons punch; 1000tons / 1600tons / 2500tons friction press; 1600t oil-hydraulic press and etc.

.jpg)

.jpg)