Construction Machinery Part

5.0~30.0 USD

| Min. Order: | 50 Piece/Pieces |

|---|---|

| Payment Terms: | T/T |

| Supply Ability: | as per customers |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Investment Casting Parts, Construction Casting, Casting Machining, Carbon Steel Forging, Carbon Steel Castings |

Product Detail

| Model No.: | C-004 |

|---|---|

| Means of Transport: | by sea / by air |

| Brand Name: | OEM |

| Specification: | carbon steel stainless steel |

| Function: | valve housings, oil industry |

| Patent Rights: | None |

| Certificate: | ISO9001 & TUV |

| Export Area: | USA CANADA EUROPE |

| Cooperative Company: | Many |

| Production Capacity: | as per customers |

| Packing: | crates |

| Delivery Date: | 60- 90 days |

Product Description

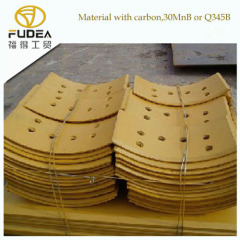

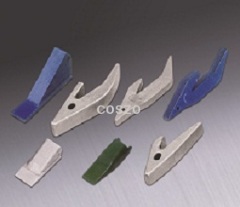

Precision Casting OEM manufacturer high pressure valve housings oilfield tool parts downhole drilling tool parts Ningbo Shanghai. export license ISO9001:2000 TUV (PED 97/23/EC & AD2000 – W0/TRD 100) exporter castings forgings CNC machined parts electrical frequency furnaces air hammer punch friction press oil-hydraulic press CNC lathes CNC machine center milling spectrometer Coordinate Measuring Machine (CMM) Surface Roughness Tester tensile yield hardness low temperature impact PT inspection X-ray hydraulic pressure test CAD Pro-E Solid works Photoshop Adobe carbon steel stainless steel WCC WCB WC6 WC9 LCC CF8 CF8M alloy steel gray iron GGG50 GGG60 GG40 grinding drilling milling.

Pengcheng is a comprehensive manufacturer in casting. We are proud to have our own pattern room for mould making and machining workshop with most advanced equipments. We can provide you our service from mould making till finish machining of parts. precision casting, precision castings

We provide our high-pressure valve castings and components to many noted valve companies and gain high reputation from our customers for the super inner quality of our parts. We using lost wax casting process to instead of the sand casting process in abroad, so our parts are more precise in dimensions, better in surface finish and more competitive in price.

1) We have 6 sets electrical frequency furnaces with relevant casting equipments.

2) We have advanced machinery for chemical analysis and different mechanical testing.

3) We are able to do PT inspection and X-ray inspection (subcontract) for samples if necessary and also we have hydraulic pressure test machine to achieve Max 30Mpa.

4) We have 50 CNC lathes and 3 CNC machine centers for your machining service along with other ordinary machinery such as lathe, milling etc.

5) We have our own pattern shop to guarantee the precision of the parts. precision casting, precision castings, steel casting unalloyed, stainless steel casting, lost wax process, composite casting process, shell moulding process, foundry products, precision cast products, steel castings low alloy, steel castings high alloy, steel castings for flam and induction hardening, steel castings heat resistant, steel castings heat-treatable

7) Each product will have its own file and process card.

8) We do 100% inspection on samples per customer's requirements. Do 100% inspection on machining dimensions in production.

Pengcheng is your ideal partner in the projects of casting process.

1) We have 6 sets electrical frequency furnaces with relevant casting equipments.

2) We have advanced machinery for chemical analysis and different mechanical testing.

3) We are able to do PT inspection and X-ray inspection (subcontract) for samples if necessary and also we have hydraulic pressure test machine to achieve Max 30Mpa.

4) We have 50 CNC lathes and 3 CNC machine centers for your machining service along with other ordinary machinery such as lathe, milling etc.

5) We have our own pattern shop to guarantee the precision of the parts. precision casting, precision castings, steel casting unalloyed, stainless steel casting, lost wax process, composite casting process, shell moulding process, foundry products, precision cast products, steel castings low alloy, steel castings high alloy, steel castings for flam and induction hardening, steel castings heat resistant, steel castings heat-treatable

7) Each product will have its own file and process card.

8) We do 100% inspection on samples per customer's requirements. Do 100% inspection on machining dimensions in production.

Pengcheng is your ideal partner in the projects of casting process.