Stamping: The operations associated with stamping are blanking, piercing, forming, and drawing. These operations are done with dedicated tooling also known as hard tooling. This type of tooling is used to make high volume parts of one configuration of part design. (By contrast, soft tooling is used in processes such as CNC turret presses, laser profilers and press brakes). All these operations can be done either at a single die station or multiple die stations — performing a progression of operations, known as a progressive die. The equipments of stamping can be categorized to two types: mechanical presses and hydraulic presses. stamping casting, precision metal stamping

(CNC) fabrication: The Computer Numerical Control (CNC) fabrication process offers flexible manufacturing runs without high capital expenditure dies and stamping presses. Tooling is mounted on a turret whichcan be as little as 10 sets to as much as 100 sets. This turret is mounted on the upper part of the press, which can range in capacity from 10 tons to 100 tons in capacity. stamping casting, precision metal stamping

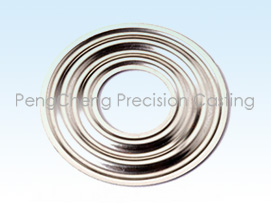

Precision Casting OEM manufacturer high pressure valve housings oilfield tool parts downhole drilling tool parts Ningbo Shanghai. export license ISO9001:2000 TUV (PED 97/23/EC & AD2000 – W0/TRD 100) exporter castings forgings CNC machined parts electrical frequency furnaces air hammer punch friction press oil-hydraulic press CNC lathes CNC machine center milling spectrometer Coordinate Measuring Machine (CMM) Surface Roughness Tester tensile yield hardness low temperature impact PT inspection X-ray hydraulic pressure test CAD Pro-E Solid works Photoshop Adobe carbon steel stainless steel WCC WCB WC6 WC9 LCC CF8 CF8M alloy steel gray iron GGG50 GGG60 GG40 grinding drilling milling