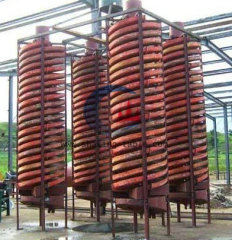

spiral separator

| Min. Order: | 1 Piece/Pieces |

|---|---|

| Payment Terms: | L/C, D/P, T/T |

| Supply Ability: | 8 sets per month |

| Place of Origin: | Henan |

Company Profile

| Location: | China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | FC&FG |

|---|---|

| Means of Transport: | Ocean, Land |

| Type: | Separator |

| Production Capacity: | 8 sets per month |

| Packing: | in container |

| Delivery Date: | 5 days |

Product Description

Application of spiral classifier:

Spiral classifier is widely used in the processing plant in closed circuits with ball mill, or used in gravity mill to classify mine sand and mud. It can also be used in the metal ore dressing procedure to classify the pulp particle size, or used for taking off the mud and water in the ore washing process.

Working Principle of spiral classifier:

Spiral classifier is a kind of classifying machine that classifies big and small mineral granules. It works according to the fact that different granules (with various sizes and weight) sink at different speeds in liquids. It can filter powders grinded from mill and rotate the coarse materials to the feeding hole of the mill and discharge filtered fine materials though the overflow pipe. The chassis of this spiral classifier is made of channel steel and the main machine is welded by armor plate. The water inlet and the shaft head come with cast iron sleeves, which are robust and abrasion resistant. Both manual-operated and automatic hoisting devices are available.

Spiral classifier is a kind of classifying machine that classifies big and small mineral granules. It works according to the fact that different granules (with various sizes and weight) sink at different speeds in liquids. It can filter powders grinded from mill and rotate the coarse materials to the feeding hole of the mill and discharge filtered fine materials though the overflow pipe. The chassis of this spiral classifier is made of channel steel and the main machine is welded by armor plate. The water inlet and the shaft head come with cast iron sleeves, which are robust and abrasion resistant. Both manual-operated and automatic hoisting devices are available.

Features of Spiral Classifier:

This classifier can filter materials and send coarse materials to the feeding mouth and discharge fine materials from the overflow pipe. The seat of the machine features channel steel material, while the body is armor plated and the spiral axle is made of cast iron for durability. The machine's lifting equipment can be used manually or electronically.

Spiral Dia. (mm) | Spiral Speed (r/min) | Trough Length (mm) | Capacity (t/h) | Power (kw) | Weight (kg) | |||

Return sand | Overflow | Transmission | Lift | |||||

FG-3 | 300 | 8.3-22 | 3000 | 30-80 | 10-30 | 1.1 | ---- | 668 |

FG-5 | 500 | 8-12.5 | 4500 | 135-210 | 32 | 1.5 | ---- | 1980 |

FG-7.5 | 750 | 6-10 | 5500 | 340-570 | 65 | 3 | ---- | 3005 |

FG-10 | 1000 | 5-8 | 6500 | 675-1080 | 110 | 7.5 | ---- | 5310 |

FC-10 | 7600 | 675-1080 | 85 | 7.5 | 0.4 | 6000 | ||

FG-12 | 1200 | 5-8 | 6500 | 1170-1870 | 155 | 7.5 | 0.4 | 8000 |

FC-12 | 8400 | 1170-1870 | 120 | 7.5 | 0.4 | 9280 | ||

2FG-12 | 6500 | 2340-3740 | 310 | 5.5*2 | 0.4*2 | 13300 | ||

2Fc-12 | 8400 | 2340-3740 | 240 | 7.5*2 | 0.4*2 | 19600 | ||

FG-15 | 1500 | 4-6 | 8300 | 1830-2740 | 235 | 11 | 0.4 | 9800 |

FC-15 | 10500 | 1830-2740 | 185 | 11 | 0.8 | 12570 | ||

2FG-15 | 8300 | 3660-5480 | 470 | 7.5*2 | 0.4*2 | 22100 | ||

2FC-15 | 10500 | 3660-5480 | 370 | 7.5*2 | 0.8*2 | 30700 | ||

FG-20 | 2000 | 3.0-5.5 | 8400 | 3240-5400 | 400 | 11 | 2.8 | 20500 |

FC-20 | 12900 | 3240-5940 | 320 | 11-15 | 2.8 | 29100 | ||

2FG-20 | 8400 | 6480-10800 | 800 | 11*2 | 2.8*2 | 36500 | ||

2FC-20 | 12900 | 6480-11800 | 640 | 15*2 | 2.8*2 | 50000 | ||

FG-24 | 2400 | 2.5-4.0 | 9200 | 4650-7450 | 580 | 11-15 | 2.8 | 25700 |

FC-24 | 14200 | 4650-7450 | 455 | 11-18.5 | 4 | 41000 | ||

2FG-24 | 9200 | 9300-14900 | 1160 | 15*2 | 2.8*2 | 45800 | ||

2FC-24 | 14200 | 9300-14900 | 910 | 18.5*2 | 4*2 | 67900 | ||

2FG-30 | 3000 | 2.0-3.2 | 14300 | 14600-23400 | 1785 | 18.5*2 | 4*2 | 73000 |

2FC-30 | 14300 | 14600-23400 | 22*2 | 4*2 | 84900 | |||