high recovery jig machine

| Min. Order: | 1 Set/Sets |

|---|---|

| Payment Terms: | L/C, D/P, T/T |

| Supply Ability: | 8 sets per month |

| Place of Origin: | Henan |

Company Profile

| Location: | China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | JT |

|---|---|

| Means of Transport: | Ocean, Land |

| Application: | Ore |

| Type: | Separator |

| Brand Name: | Yuhu |

| Production Capacity: | 8 sets per month |

| Packing: | in container |

| Delivery Date: | 4 days |

Product Description

RectangleCompartment Side Way Action Type Jig machine has two types. One is leftcompartment side way jig machine, another is right compartment side wayjig machine. The jig machine has fixed screen. It is available inseparating metallic ores, such as tungsten and gold placer deposits aswell as beneficiated tin ore, which not only can be separated finematerials, but coarse also. The largest feed size is 6-8mm but it can be12mm in few cases.

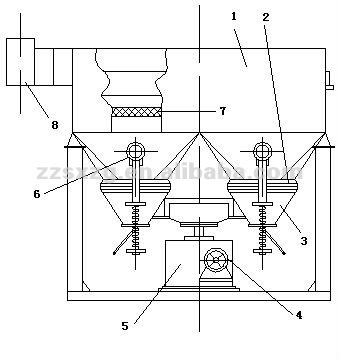

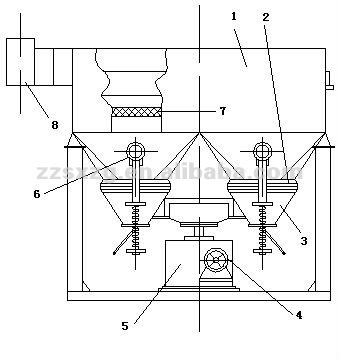

Jigger structure:

1. Trough2. Rubber diaphragm3. Tapered funnel 4. Electromagnetic speed control motor

5. Cam box6. Water supply pipe flange 7. sieve 8. Feeding trough

Jig machine in workshop:

Jig MachineTechnical Specification

Name and Specification | Jig chamber No | Jig Area(m2) | Feed Size (mm2) | Production Capacity(t/h) | Stroke (mm) | Stroke Per Minute(r/min) | Hutch Water (t /h) | Water Pressure (kilo/cm2) | Electromotor | Weight (kg) |

Power kw | ||||||||||

100×150 Diaphragm Jig | 1 | 0.015 | -3 | 0.018-0.6 | - | 420 | - | 1-1.5 | 0.55 | 130 |

300×450 Double Chamber Diaphragm Jig | 2 | 0.27 | -12 | 3-6 | 0-26 | 322 | 2-4 | 1-1.5 | 1.1 | 745 |

1000×1000 Below Pulsation Cone Diaphragm Jig | 2 | 2 | 1-5 | 10-25 | 0-26 | 200-350 | 60-80 | 0.6-2 | 1.5 | 1700 |

370×360 Below Pulsation Cone Diaphragm Jig | 2 | 0.274 | 6 | 1-3 | 5-25 | 200-250 | 2-5 | - | 1.1 | 240 |

Trapezoid Side Way Action Type Jig | 3 | 2.7 | -3 | 12.5-37.5 | 13-21 | 170-230 | 60-90 | 2 | 1.1 | 2000 |

670×920 Jig | 2 | 1.44 | 4-8 | 7-10 | 18-24 | 240-300 | - | - | - | - |

A green jig machine in shed!

How to change stroke?

Basedon the size of ore, we can change the stroke of connecting rod andchoose different stroke to make the best jigging effect. The method ofaltering stroke per minute is to exchange a smaller belt pulley butthere are two strokes per minute: 322r/m; 420r/m. The method of choosingstroke is to loose bolt and screw cap, take out bowel and move therelative place between eccentric adjusting sieve and eccentric shaft sothere are 11 different strokes (0-25.3mm).

Gravity separation and mineral processing equipment

Provide you with the bestsolution of mineral processing!