Permanent neodymium double loud speaker magnet for sale

| Min. Order: | 200 Piece/Pieces |

|---|---|

| Trade Term: | FOB,CFR,CIF |

| Payment Terms: | L/C, D/A, T/T, WU |

| Supply Ability: | 1000 pcs per day |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Model No.: | SM-0110 |

|---|---|

| Means of Transport: | Ocean, Air |

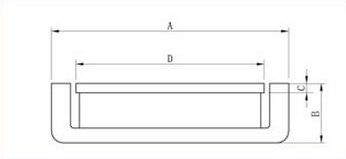

| Shape: | Cup Shape |

| Application: | Industrial Magnet |

| Type: | Permanent |

| Composite: | Neodymium Magnet |

| Brand Name: | LEC |

| Size: | Custom |

| Material: | Neodymium magnet + steel +PVC |

| Application: | loud speaker |

| Type: | Permanent |

| Tolerance: | ±0.1 mm |

| HS Code: | 85051190 |

| Certificate: | ISO9001:2008 |

| Production Capacity: | 1000 pcs per day |

| Packing: | carton / pallet |

| Delivery Date: | 15~25 days |

Product Description

All speakers don't use magnets. Only magnetic speakers use a magnet to produce mechanical vibration (sound) through the interaction between the magnetic field created by the pulsating electronic signals passing through a coil suspended in the strong magnetic field of the magnet. Other types of speakers like piezo speakers (for example, buzzers in wrist watches don't use a magnet. Piezo speakers use the piezo electric effect. They generate mechanical vibration by applying an electric signal to a piezo electric crystal.

Due to the sizes of the magnet, there may be variations on pull strength. Please contact our customer service team for more information.

Part No. | U YOKE(A×B) | Magnet | Washer(D×C) | Air Gap(mm) | MagneticFlux(GS) |

SM-0110-13 | 18×5 | NdFeB | φ12.8×1.5 | 0.700 | |

SM-0110-13A | 18×6 | NdFeB | φ12.95×2 | 0.575 | |

SM-0110-13B | 21.4×7 | NdFeB | φ12.95×1.5 | 0.600 | |

SM-0110-13C | 26.5×4.9 | NdFeB | φ12.95×1.5 | 0.750 | 6500 |

SM-0110-13E | 18.5×6 | NdFeB | φ12.95×1.5 | 0.675 | |

SM-0110-13F | 18×6.5 | NdFeB | φ13×2 | 0.625 | |

SM-0110B-13 | 21.5×8.5 | NdFeB | φ12.95×2 | 0.625 | |

SM-0110-19 | 27.2×7 | NdFeB | φ18.95×2 | 1.125 | |

SM-0110-19A | 26×6.5 | NdFeB | φ19×1.5 | 1.250 | |

SM-0110-19B | 26×6.5 | NdFeB | φ19×2 | 1.250 | |

SM-0110-19C | 24.6×8.3 | NdFeB | φ18.6×1.3 | 1.000 | 11000 |

SM-0110-19D | 27.5×8.5 | NdFeB | φ19×2 | 0.750 | |

SM-0110-19DA | 27.3×8.5 | NdFeB | φ19×2 | 0.750 | 10000 |

SM-0110-19F | 26.1×8 | NdFeB | φ19×2 | 0.750 | |

SM-0110-19G | 26×9 | NdFeB | φ19×2.5 | 0.625 | |

SM-0110-20 | 26×7 | NdFeB | φ19.95×2.5 | 0.775 | |

SM-0110-20A | 26×7 | NdFeB | φ19.95×2 | 0.775 | 10000 |

SM-0110-20B | 26×6.5 | NdFeB | φ19.95×2 | 0.775 | |

SM-0110-20C | 26×7.5 | NdFeB | φ19.95×2 | 0.775 | |

SM-0110-20D | 26×8 | NdFeB | φ19.95×2 | 0.775 | |

SM-0110-20E | 25.9×7.5 | NdFeB | φ19.9×1.5 | 0.800 | |

SM-0110-25 | 33×9.3 | NdFeB | φ24.92×3.5 | 0.840 | |

SM-0110-25A | 32.6×10.2 | NdFeB | φ24.92×3.5 | 0.840 | |

SM-0110-25B | 33×8.5 | NdFeB | φ24.95×3 | 1.025 | 10500 |

SM-0110-25C | 37×9 | NdFeB | φ25×2.5 | 0.950 | |

SM-0110-25D | 33×10 | NdFeB | φ24.92×3.5 | 1.040 | |

SM-0110-25E | 36.8×10 | NdFeB | φ24.95×3.5 | 0.875 | |

SM-0110-25F | 32×7.6 | NdFeB | φ24.95×2 | 0.925 | 11000 |

SM-0110-25FA | 32×8.1 | NdFeB | φ24.95×2 | 0.925 | 11000 |

SM-0110-25FE | 32×8.1 | NdFeB | φ24.95×5×2 | 0.925 | 10500 |

SM-0110-25G | 36.2×7.5 | NdFeB | φ25.1×2 | 0.700 | 10500 |

SM-0110-25J-A | 32×6.7 | NdFeB | φ24.95×1.5 | 0.925 | 10000 |

SM-0110-25K | 32×7.5 | NdFeB | φ24.95×1.5 | 0.725 | 13000 |

SM-0110-25L | 35.8×18.7 | NdFeB | φ24.95×4 | 1.025 | |

SM-0110-25M | 32×8.6 | NdFeB | φ24.95×3 | 0.925 | 10000 |

SM-0110-25N | 33×8.5 | NdFeB | φ24.95×2 | 0.875 | 11500 |

SM-0110-25P | 37×11.3 | NdFeB | φ24.95×3 | 0.725 | |

SM-0110-25Q | 40×9 | NdFeB | φ24.9×3 | 1.000 | 9800 |

SM-0110-25R | 32×10 | NdFeB | φ25×3 | 0.625 | |

SM-0110A-25 | 32×6.7 | NdFeB | φ24.95×1.5 | 0.925 | |

SM-0110A-25A | 32×6.6 | NdFeB | φ25×1.5 | 0.850 | |

SM-0110A-25B | 32×6.6 | NdFeB | φ25×φ3.2×1.5 | 0.850 | |

SM-0110A-25F | 32.1×9 | NdFeB | φ24.9×2 | 0.850 | |

SM-0110-28 | 35×8.7 | NdFeB | φ27.66×φ6×2.6 | 0.920 | |

SM-0110-28A | 36×8.3 | NdFeB | φ27.6×2 | 0.750 | |

SM-0110-28B | 35×8.7 | NdFeB | φ27.66×φ6×2.6 | 0.920 | |

SM-0110-29 | 36×7.5 | NdFeB | φ29×1.5 | 0.500 |

Note:

1.The surface treatings are zinc OR nickel coated.

2.The Oper.Temp. are 100 ℃.

3.Customer designs are acceptable.