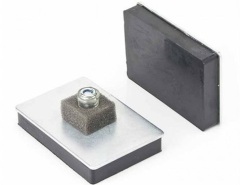

Rubber coated base magnet used for TAXI roof sings

| Min. Order: | 200 Piece/Pieces |

|---|---|

| Trade Term: | FOB,CFR,CIF |

| Payment Terms: | L/C, D/A, T/T, WU |

| Supply Ability: | 1000 pcs per day |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

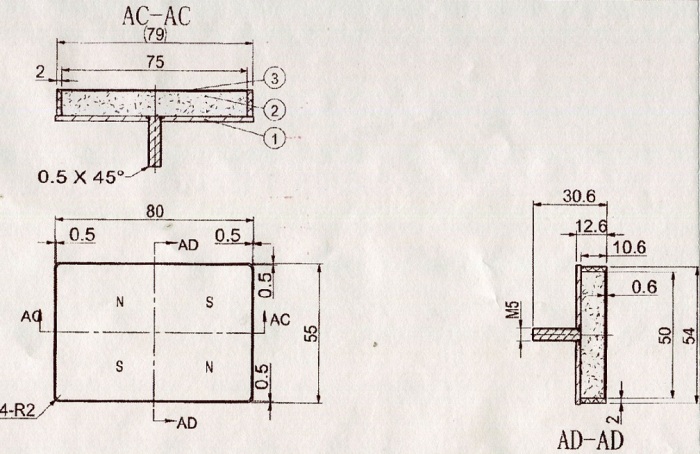

| Model No.: | RCM-0117 |

|---|---|

| Means of Transport: | Ocean, Air |

| Shape: | Cup Shape |

| Application: | Industrial Magnet |

| Type: | Permanent |

| Composite: | Neodymium Magnet |

| Brand Name: | LEC |

| Size: | Custom |

| Material: | Neodymium magnet + steel +PVC |

| Application: | Holding |

| Type: | Permanent |

| Tolerance: | ±0.1 mm |

| HS Code: | 85051190 |

| Certificate: | ISO9001:2008 |

| Production Capacity: | 1000 pcs per day |

| Packing: | carton / pallet |

| Delivery Date: | 15~25 days |

Product Description

The car rooftop magnet (Magnetic Pads, MagPad) is designed for applications where high shear strength is required with minimum scratching. The car roof magnet is a magnetic clamping assembly with a soft polyurethane coating. The soft polyurethane coating causes almost zero abrasion but gives a much higher surface friction. Most magnets have a strong direct pull force but they can be made to slide along a surface with about 20% of the direct pull force when used on steel.

The car rooftop magnet has a strong direct pull force but the increased friction of the polyurethane means that it takes around twice the direct pull force to get the magnet to slide. This means that the car rooftop magnet resists sliding along a ferromagnetic steel surface better than magnets without the polyurethane coating. It can provide immense resistance to shear forces when mounted on a smooth metal surface, as typically found on motor vehicle body parts.

Due to the tolerance of the rubber, there may be variations on pull strength. Please contact our customer service team for more information.