Permanent bonded neodymium magnets

| Min. Order: | 200 Piece/Pieces |

|---|---|

| Trade Term: | FOB,CIF |

| Payment Terms: | Paypal, L/C, T/T |

| Supply Ability: | 5,000 pc per day |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Model No.: | BNB-0908 |

|---|---|

| Means of Transport: | Ocean, Air |

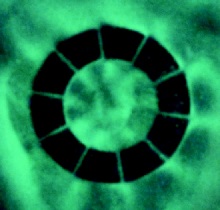

| Shape: | Ring |

| Application: | Motor Magnet |

| Type: | Permanent |

| Composite: | Neodymium Magnet |

| Brand Name: | LEC |

| Br: | 450 - 770 mT |

| BHmax: | 24 - 92 kJ/m 3 |

| Hcb: | 199 - 430 kA/m |

| Hcj: | 477 - 637 kA/m |

| Certificate: | ISO9001:2008 |

| Production Capacity: | 5,000 pc per day |

| Packing: | cartons / pallets |

| Delivery Date: | 10-18 days |

Product Description

Features of permanent bonded neodymium magnets:

1. Higher Magnetic Strength due to higher magnetic particle density,approximately 3 times stronger than ceramic magnet material.

2. The magnetic material is isotropic, it can be magnetized through any direction, including multi-polar arrangements.

3. Good mechanical strength. Because the material is in an epoxy binder, it can be machined on a mill or lathe. However, the material will not support a thread, so holes cannot be tapped.

4. Good corrosion resistance after Epoxy coating.

5. "Tight" tolerances off tool

6. Temperature Range -40c – 165c

Permanent bonded neodymium magnets have been incorporated into numerous end market applications and been used in the applications that require higher performance, smaller size, and greater efficiencies.

Due to the excellent magnetic performance and manufacturability, Permanent bonded neodymium magnets are more and more widely used in various application fields. It is mainly used in rotating assemblies, such as micro-motor for computer, and also used for speaker, electronic clocks, electronic cameras, hard disk drive, optical disk drive motors, fax, copier and printer stepper motors, Consumer electronics (personal video recorders & MP3 music players), Automotive & industrial applications (instrument panel motors and air bag sensors) and all kinds of motor and key components in cars application.

With the computer was popular in the office and families, the widespread use of car, this will further promote the application of bonded neodymium magnets.

The performance of permanent bonded ndfeb magnets

BNP-3 | BNP-6 | BNP-8 | BNP-8SR | BNP-9H | BNP-10 | BNP-11 | BNP-12L | |

Br (mT) | 450-510 | 590-650 | 620-670 | 620-66 | 650-700 | 680-720 | 700-740 | 730-770 |

Br (Gs) | 4500-5100 | 5900-6500 | 6200-6700 | 6200-6600 | 6500-4000 | 6800-7200 | 7000-7400 | 7300-7700 |

Hcb(kA/m) | 199-263 | 302-374 | 390-454 | 405-470 | 421-484 | 413-477 | 430-493 | 366-430 |

Hcb(kOe) | 2.5-3.3 | 3.8-4.7 | 4.9-5.7 | 5.1-5.9 | 5.3-6.1 | 5.2-6.0 | 5.4-6.2 | 4.6-5.4 |

Hcj (kA/m) | 477-597 | 597-796 | 636-796 | 955-1114 | 915-1034 | 636-796 | 636-796 | 517-637 |

Hcj(kOe) | 6.0-7.5 | 7.5-10.0 | 8.0-10.0 | 12.0-14.0 | 11.5-13.0 | 8.0-10.0 | 8.0-10.0 | 6.5-8.0 |

(BH)max (kJ/m 3) | 24-32 | 44-53.6 | 60-68 | 65.6-72 | 72-80 | 76-84 | 80-88 | 84-92 |

(BH)max (MGOe) | 3.0-4.0 | 5.5-7.0 | 8.0-9.5 | 8.2-9.0 | 9.0-10.0 | 9.5-10.5 | 10.0-11.0 | 10.5-11.5 |

Tw/ ℃ | 120 | 120 | 120 | 160 | 160 | 120 | 120 | 110 |

Examples of Magnetization Picture of the permanent bonded ndfeb magnets

The factory has over 15 years experience on manufacturing and technology on the bonded neodymium magnets. With its own molding workshop, the factory can accomplish entire production process in-house from molding design, manufacturing and maintenance. The plant has obtained automatic production with rigorous Japanese-type management and precise equipments imported.