High efficiency Static pass box 230V EC Centrifugal Fan impeller 310 for clean room

| Min. Order: | 100 Piece/Pieces |

|---|---|

| Payment Terms: | L/C, T/T |

| Supply Ability: | 5000PCS per month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | DC Motor, 24V 48V DC Axial Fans, EC Motor, Centrifugal Fan, Custom Electric DC Brushless Motor |

Product Detail

| Model No.: | R3BE310/070B |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Type: | Air Handling Unit |

| Certification: | RoHS |

| Brand Name: | Green Power |

| Material: | Galvanised sheet steel |

| Type of protection: | IP42 |

| approvals: | CCC,CE |

| Insulation class: | B |

| Impeller Dimension: | 310mm |

| weight: | 4.4KGS |

| power: | 510W |

| USES: | ventilation |

| speed: | 2600RPM |

| Blade height: | 70mm |

| Production Capacity: | 5000PCS per month |

| Packing: | PALLET |

| Delivery Date: | 30 days for 5000 pcs After receipt the payment |

Product Description

EC fan technology –the best solution

·We use modern EC fans in our compact air-conditioning units.

·In contrast to the usual AC fans, they have an EC permanent magnet direct-current motor.

·In contrast to the usual AC fans, they have an EC permanent magnet direct-current motor.

·Commutation with this new technology involves semi-conductor modules – thus electronic and non-wearing.

·Integrated monitoring functions protect both motor and electrical equipmentfrom the effects of blockage, phasing failure and excess temperature and thus ensure reliable operations and lengthy service life.

·Internal electricalequipment continuously regulates the air volume.

·Compliant to ERP 2015,future proofed fan and motor assemblies.

High efficiency Static pass box 230V EC Centrifugal Fan impeller 310 for clean room data sheet:

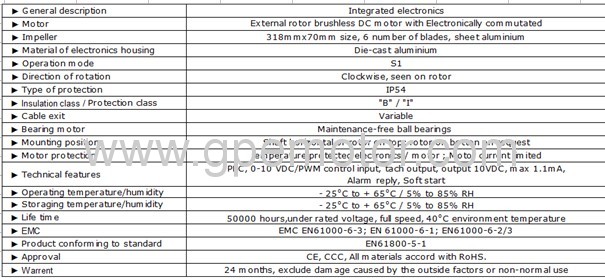

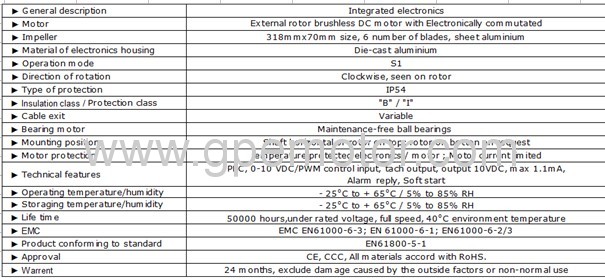

High efficiency Static pass box 230V EC Centrifugal Fan impeller 310 for clean room technical feature:

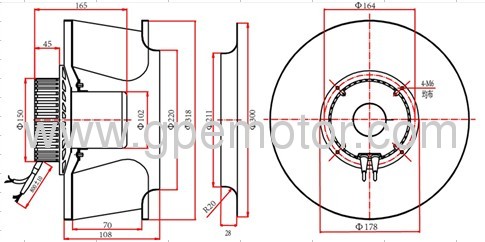

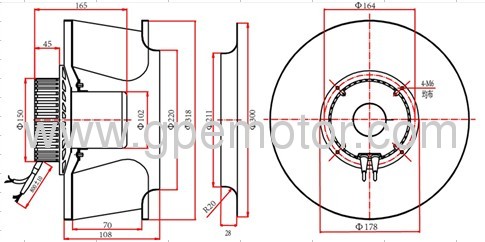

High efficiency Static pass box 115V/230V EC Centrifugal Fan impeller 310 for clean room technical drawing:

Application

Static pass boxes with backward EC Centrifugal Fan avoids cross contamination and also minimize the entry of contaminants into the clean room while transferring the material from one classified area to another.

115V/230V EC Centrifugal Fan impeller 310 for clean room packing photo

·Integrated monitoring functions protect both motor and electrical equipmentfrom the effects of blockage, phasing failure and excess temperature and thus ensure reliable operations and lengthy service life.

·Internal electricalequipment continuously regulates the air volume.

·Compliant to ERP 2015,future proofed fan and motor assemblies.

High efficiency Static pass box 230V EC Centrifugal Fan impeller 310 for clean room data sheet:

| Rated voltage | VAC | 230 | 115 | ||||

| Frequency | Hz | 50/60 | 50/60 | ||||

| Rated voltage range | VAC | 207~253 | 92~125 | ||||

| Power input | W | 510 | 355 | ||||

| Speed | RPM | 2600 | 2300 | ||||

| Airflow | M3/H | 3085 | 2600 | ||||

| Current draw | A | 3.20 | 4.20 | ||||

| Noise | dBA | 78 | 75 | ||||

| Min.ambient temperature | oC | -25 | -25 | ||||

| Max.ambient temperature | oC | 60 | 60 | ||||

| Net weight | kg | 4.4 | 4.4 | ||||

High efficiency Static pass box 230V EC Centrifugal Fan impeller 310 for clean room technical feature:

High efficiency Static pass box 115V/230V EC Centrifugal Fan impeller 310 for clean room technical drawing:

Application

Static pass boxes with backward EC Centrifugal Fan avoids cross contamination and also minimize the entry of contaminants into the clean room while transferring the material from one classified area to another.

Pharmaceutical industries.

Chemical research laboratories.

Electronic industry.

Semiconductor production.

Food processing industry.

115V/230V EC Centrifugal Fan impeller 310 for clean room packing photo