Bypass control EC centrifugal fan blower for fresh air Green Heat Pump with Panasonic rotary compressor

| Min. Order: | 100 Piece/Pieces |

|---|---|

| Payment Terms: | L/C, T/T |

| Supply Ability: | 2,000-3,000PCS per month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | DC Motor, 24V 48V DC Axial Fans, EC Motor, Centrifugal Fan, Custom Electric DC Brushless Motor |

Product Detail

| Model No.: | R3BE400 |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Category: | Heat Pump |

| Capacity Type: | Others |

| Certification: | CE |

| Brand Name: | Green Power |

| Power supply: | 115V, 230V or 380VAC |

| EC Motor: | Brushless EC Motor |

| Impeller material: | Sheet aluminium |

| Speed control: | 0-10V/PWM signal |

| Approval: | CCC, CE, VDE, UL |

| Starting mothod: | Soft starting |

| Protection type: | Over-temperature protected |

| Applications: | Heat Recovery fresh air handling units |

| Production Capacity: | 2,000-3,000PCS per month |

| Packing: | Carton/Pallet |

| Delivery Date: | 30 days for 2000 pcs After receipt the payment |

Product Description

GP TECH has independently developed EC Motor (brushless DC motor with Electronically commutated) , used in heat pump fan manufacturing areas, bringing better performance, higher efficiency, lower energy consumption, quieter operation , in the heat pump fan in use can save 60% of energy.

The various advantages of the EC Centrifugal fan with EC technology resulting for both air and drive engineering:

· High Efficiency resulting in energy saving and fast amortization

· Continuously variable speed control by analog or digital input

· Simple speed control or more complex closed-loop control options can be integrated at competitive cost

· Cross linked bad bus-connected installations are easy to achieve

· High performance density, i.e. compact design

· Temperature and airflow-dependent speed control options (intelligent fans)

· Speed and/or air flow monitoring

· Long life expectancy and robust design comparable to and asynchronous motor

· Built-in protective systems ( e.g. Looked rotor protection, reverse polarity protection)

· Direct supply from .line voltage 230 V AC options

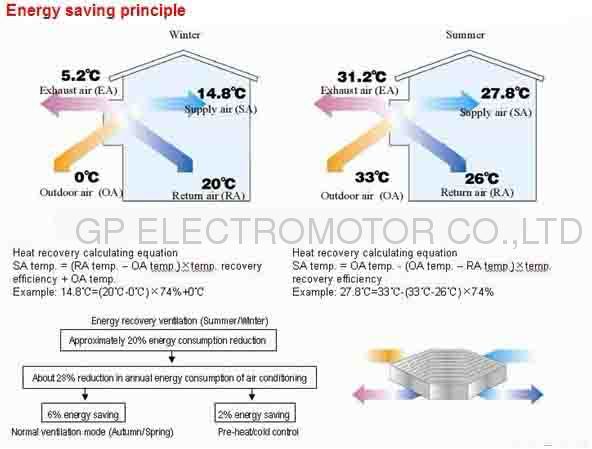

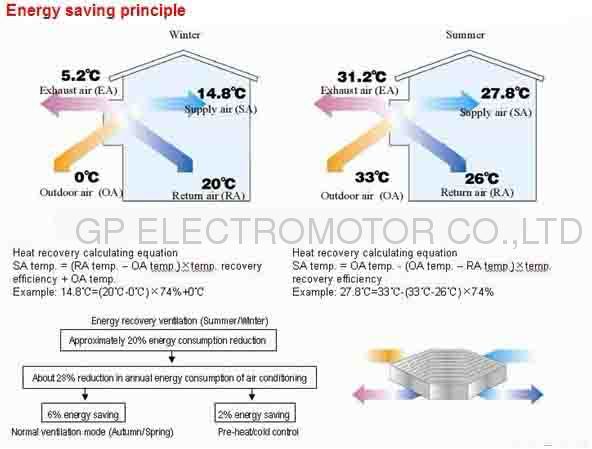

Working principle of Electricalheater bypass control R410a refrigerant energy saving EC Centrifugal fan freshair heat pump

Energy saving EC Centrifugal fan freshair heat pump

It can expel the stale air indoor out of room, meanwhile supplying the fresh airoutside into the room, by using the advanced heat/energy recovering technology,the energy can exchange taking advantage of the difference of the temperatureand humidity between indoor and outdoor air. By this means, it can not onlysmooth away the problem of indoor pollution, but also saving energy.

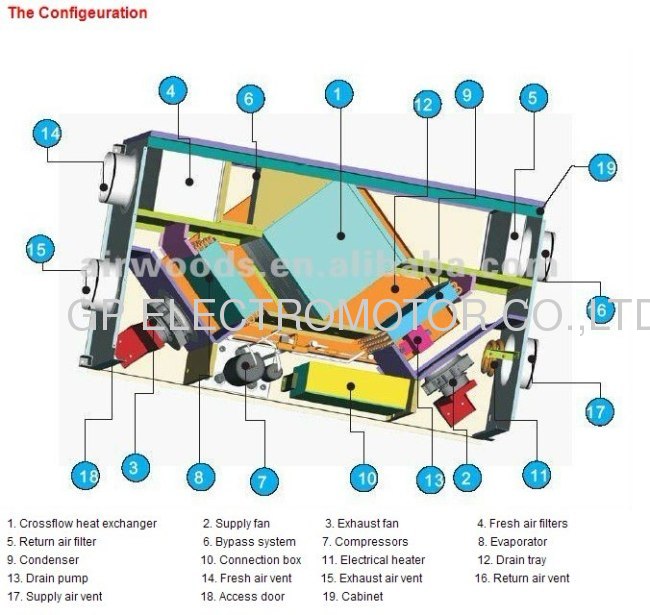

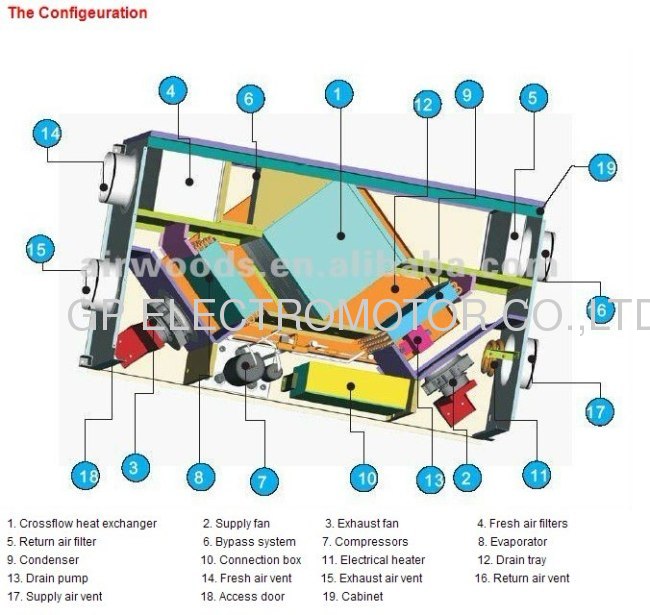

The Configeuration of Energy saving heat pump with EC centrifugal fan

Other EC centrifugal fan blower for New Green Energy Saving Heat Pump

It can expel the stale air indoor out of room, meanwhile supplying the fresh airoutside into the room, by using the advanced heat/energy recovering technology,the energy can exchange taking advantage of the difference of the temperatureand humidity between indoor and outdoor air. By this means, it can not onlysmooth away the problem of indoor pollution, but also saving energy.

The Configeuration of Energy saving heat pump with EC centrifugal fan

Other EC centrifugal fan blower for New Green Energy Saving Heat Pump