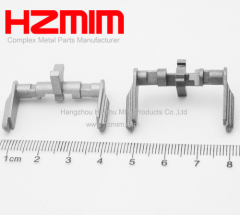

Metal Injection Molding (MIM) Parts

| Min. Order: | 5000 Piece/Pieces |

|---|---|

| Place of Origin: | Jiangsu |

Company Profile

| Location: | China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Service |

Product Detail

| Model No.: | mim China |

|---|---|

| Means of Transport: | Ocean |

| Brand Name: | Jiangsu Tech |

| As same as the production of plastics production complex shape of small metal parts (0.1-100g): | Parts properties of homogeneous, high dimensional accuracy and high relative density (≥ 95%) |

| Good surface smoothness: | Product quality stability |

| high efficiency: | easy to achieve high-volume,large-scale production |

| Packing: | Carton |

Product Description

Concepts:

Metal Injection Molding (MIM) Process is the new manufacturing process technology combining conventional PM with Plastics Injection Molding. First, metal powder is mixed with binder , and becomes granulated feedstock needed by injection molding mechine. Second, the viscous flow characteristics of the polymer is gifted with the mixture, and help shape of the cavity filled with powder and packed uniformity. Third ,the green part is debind and sintered. Some sintered products might need second densification process, heat treatments or machining. Not only has MIM products same plastic injection molding products as the complex shapes and high precision, but also as forging parts close to the physical, chemical and mechanical properties. MIM technology can meet mass production of small, sophisticated and complex three-dimensional shape.

Metal Injection Molding (MIM) Process is the new manufacturing process technology combining conventional PM with Plastics Injection Molding. First, metal powder is mixed with binder , and becomes granulated feedstock needed by injection molding mechine. Second, the viscous flow characteristics of the polymer is gifted with the mixture, and help shape of the cavity filled with powder and packed uniformity. Third ,the green part is debind and sintered. Some sintered products might need second densification process, heat treatments or machining. Not only has MIM products same plastic injection molding products as the complex shapes and high precision, but also as forging parts close to the physical, chemical and mechanical properties. MIM technology can meet mass production of small, sophisticated and complex three-dimensional shape.

Material:

Fe-based alloy steel, stainless steel, nickel-based alloys, tungsten alloy, carbide, titanium, magnetic materials, Kovar alloy, fine ceramics, etc..

Fe-2Ni, Fe-8Ni; 316L ,17-4PH ;WC-Co; Al2O3, ZrO, SiO2; W-Ni-Fe, W-Ni-Cu, W-Cu; Ti,Ti-6Al-4V; Fe, Fe14Nd2B, SmCo5

Fe-2Ni, Fe-8Ni; 316L ,17-4PH ;WC-Co; Al2O3, ZrO, SiO2; W-Ni-Fe, W-Ni-Cu, W-Cu; Ti,Ti-6Al-4V; Fe, Fe14Nd2B, SmCo5