Flush Grid9525 plastic conveyor belt heat resistant feature

| Min. Order: | 20 Square Meter |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | T/T, WU |

| Supply Ability: | 1000 suquer meter/month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | Plastic Belt Conveyor, Perforated Flat Top Modular Belt Conveyor, Flat Top Belt Conveyor, Industrial Conveyor Belt, Food Conveyor Belt |

Product Detail

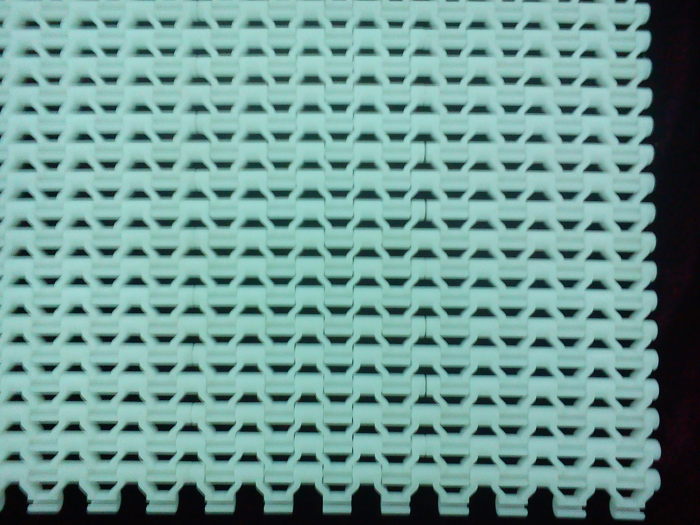

| Model No.: | RW-YY-Flush Grid 9525 |

|---|---|

| Means of Transport: | Ocean, Air |

| Structure: | Belt Conveyor |

| Material: | Plastic |

| Material Feature: | Heat Resistant |

| Brand Name: | OEM |

| Material: | POM/PP |

| Pitch: | 10mm |

| Color: | Various color |

| Width:: | according for clients |

| Open area: | 24% |

| Surface:: | Flush Grid |

| Assembling method:: | Bulke design ,without using rods |

| Backflex Radius(min):: | 8mm |

| Place of Origin:: | Zhejiang,China (Mainland) |

| Cleanability: | Easy |

| Production Capacity: | 1000 suquer meter/month |

| Packing: | by carton |

| Delivery Date: | 11-16day |

Product Description

Flush Grid conveyor belt used in food industry

plastic modular conveyor belt component

Belt data

Belt type | Material | Temperature range | Working load(max.) | Weight | Backflex radius(min.) | |

dry | wet | N/m(21ºC) | kg//㎡ | mm | ||

FG9525 | POM | -30 TO 75 | -30 TO 75 | 10800 | 4.4 | 8 |

PP | 1 TO 75 | 1 TO 75 | 7300 | 3.6 | 8 | |

In the past the beverage bottling industry was very noisy due to the use of metallic chains working at high speed. Nowadays the plastic modular belt system

reduces the noise rate at very acceptable levels.

The use of metallic chains also entailed a high cost in mechanical maintenance, as well as a great consumption of lubricants for decreasing the friction

coefficient in order to avoid their premature wear. The maintenance cost of the plastic materials used for manufacturing the Rellwinmodular belts is the lowest,

as they do not need any lubrication, which avoids not only the lubricant expenditure, but also the rejection of bottles due to their impregnation with those liquids.

This belt enables product transfers without finger plates or uncomfortable dead plates, and with a very low noise level at working speeds of 150 meters

per minute.

modular conveyor belt Rellwin belts are made of plastic modules. belts are assembled in an interlocked, bricklayed pattern with full-length hinge rods – an

inherently strong design.

Strong and reliable

The FG9525 modular conveyor belt has increased performance in the following industries/applications:

1. Bakery applications including pan handling and incline/decline box or pan applications.

2. Meat or poultry applications including packaging lines and incline box conveyors.

3. Beverage applications including depalletizers, accumulation tables and incline case conveyors.

4. Can manufacturing applications including palletizers, mass handling and accumulation tables.

5. Corrugated applications including downstacker, corrugator take off, transfer car and WIP storage.

6. Tire applications including wigwag, extruder takeaway and inspection applications.

7. Material handling applications including incline applications, palletizers and packaging lines.

We are China modular belt manufacturer offer best modular belt OEM, ODM,service.

Trade Terms.:

1. Payment By T/T or Western Union or Paypal.

100% payment if the total amount is less than USD 500.00

2. Lead time: 5~15 working days, subject to the order quantity.

3. Delivery ways: by sea, by air . DHL , UPS door to door service for samples transportation ,

4. Free sample: 2pcs

Our service:

1. Reply your enquiry in 24 working hours

2. Experienced staffs answer all your questions in fluent English/

3. Customized design is available, OEM&ODM are welcomed

4. Exclusive and unique solution can be provided to our customer by our well-trained and professional engineers and staffs.

5. Special discount and protection of sales area provided to our distributor.

Company and Products information related:

Ningbo Rellwin Industry Co.,ltd.