Flush grid modular conveyor Belt straight run RW-YY- A24

| Min. Order: | 20 Square Meter |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | T/T, WU |

| Supply Ability: | 1000 suquer meter/month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | Plastic Belt Conveyor, Perforated Flat Top Modular Belt Conveyor, Flat Top Belt Conveyor, Industrial Conveyor Belt, Food Conveyor Belt |

Product Detail

| Model No.: | RW-YY-Flush Grid A24 |

|---|---|

| Means of Transport: | Ocean, Air |

| Structure: | Belt Conveyor |

| Material: | Plastic |

| Material Feature: | Heat Resistant |

| Brand Name: | OEM |

| Material: | PE/PP/POM |

| Pitch: | 24mm |

| Color: | Various color |

| Rod diameter: | 4.6mm |

| Thickness:: | 11mm |

| Open Area: | multiples of 8mm.minimum 16mm |

| Surface:: | Flush Grid |

| Belt width:: | Multiples of 10 mm |

| Assembling method:: | Connected with rods |

| Export market: | Global |

| Production Capacity: | 1000 suquer meter/month |

| Packing: | by carton |

| Delivery Date: | 12-17day |

Product Description

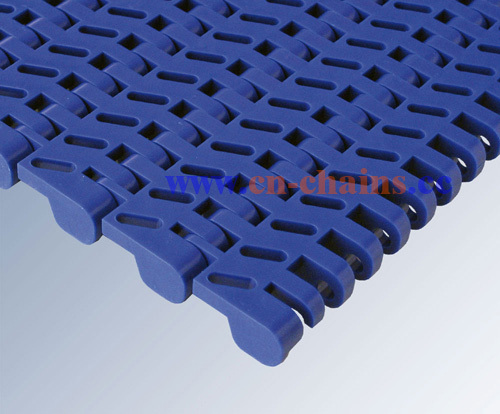

Flush Grid series A24 modular conveyor belt

Flush Grid modular conveyor belt with flight

Series A24 Flush Grid has oval perforations of 9.5 x 3 mm which endow it with a 30% open area. This conveyor belt is used in applications requiring

drainage or airflow, like defrosting or drying.

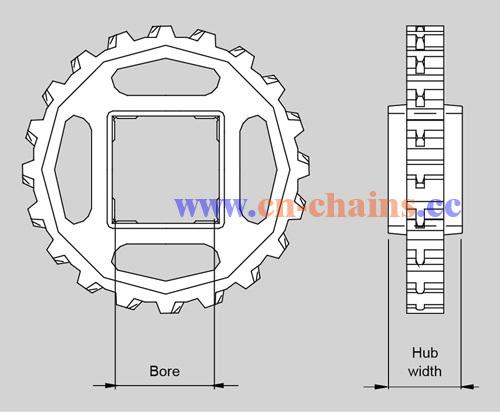

We also have sprockets to be used with motor drum in applications needing a special cleaning or in conveyors in which it is not possible to place the

motor in the outside due to problems of space or safety.

To calculate the necessary minimum quantity of sprockets for the drive shaft as well as for the idle one

Belt date

Material of the belt | Material of the rod | Belt strength (kg/m) | Temperature range(°C) | Belt weight(kg/㎡) |

PP | PP | 753 | -1 TO 104 | 4.90 |

PP | PE | 260 | -50 TO 65 | 5.12 |

AC | PP | 1850 | 1 TO 90 | 7.10 |

AC | PE | 1414 | -40 TO 65 | 7.14 |

Sprockets data

No.of teeth | Diameter pitch | Bore for square shaft |

Hub width | |

mm | in | |||

7 | 55.31 | 20 | - | 20 |

13 | 100.25 | 40 | 1.5 | 40 |

20 | 153.41 | 40 60 | 1.5 | 40 |

25 | 191.48 | 40 60 90 | 1.5 | 40 |

The current methods for producing wine are far away from those used by our ancestors. Nowadays, derived from complex and costly technical studies,

meticulous systems of detailed care are carried out regarding the soil, the plant, the fruit, and, of course, its transformation in wine in order to

obtain the best quality.

But for all this, it is essential a conveying and handling aseptic system for cooling the grapes, selecting them, and carrying them to the destemmer with

the care and asepsis required by the most demanding quality control.Our modular belts have been carrying out this task in this selective industry

successfully for some years, so that they are installed in the most famous wineries.

modular conveyor belt Rellwin belts are

made of plastic modules. belts are assembled in an interlocked, bricklayed pattern with full-length hinge rods – an

inherently strong design.

Strong and reliable

The SERIES A24 modular conveyor belt has increased performance in the following industries/applications:

1. Bakery applications including pan handling and incline/decline box or pan applications.

2. Meat or poultry applications including packaging lines and incline box conveyors.

3. Beverage applications including depalletizers, accumulation tables and incline case conveyors.

4. Can manufacturing applications including palletizers, mass handling and accumulation tables.

5. Corrugated applications including downstacker, corrugator take off, transfer car and WIP storage.

6. Tire applications including wigwag, extruder takeaway and inspection applications.

7. Material handling applications including incline applications, palletizers and packaging lines.

We are China modular belt manufacturer offer best modular belt OEM, ODM,servic

Plastic belt is the use of engineering plastics production belt plate assembly made of modular belt with interlocking brickway interleaved mode or by the

total length of the pin assembly together, this design is fundamentally improve the conveyor belt strength.Flights and side panels can also be interlocked

with the hinge pin has become integral parts of the conveyor belt. Plastic belt has too much forms, assembling flexible, easy to replace. There are openings in

the form, flat, ribs, ball, slip and other forms. Apply to pigs, sheep, chickens, ducks slaughtered , cutting and processing, puffed food production line,

fruit grading, packing lines, fish processing production line, frozen food production line, battery manufacturing, beverage manufacturing, canning

industry, agro-industry, chemical industry , electronics, rubber and plastic manufacturing industry, the cosmetics industry, the general transport operations

Advantage

Precision molding process ensures optimum flatness.

High wear resistance and low friction coefficient

High work load

Our services

1. Warranty time: 1 year. The conveyor belt / chains / sprockets which supplied by our company could be exchanged when it have quality problems,such as it was broken in installing , the pin run out from chains or the chains parted . But if the user use it in a wrong way, we can not provide any goods for free .

2. Payment: T/T , L/C , Western Union or Paypal .

3. Lead time: 5~15 working days, subject to the order quantity.

4. Shipment: by sea, by air,door to door service for samples transportation.

5. OEM service : we have our own R.D team . If you want to purchase the belt which we have not or you have your own design , we would like to make mold for you for free , only have the condition of requiring continuous orders ,and first order must be more than 60 square meters .

Company and Productsinformationrelated:

Ningbo Rellwin IndustryCo.,ltd.