series C12 Flush Grid conveyor belt Straight running conveyor belt

| Min. Order: | 15 Square Meter |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | T/T, WU |

| Supply Ability: | 1000 suquer meter/month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | Plastic Belt Conveyor, Perforated Flat Top Modular Belt Conveyor, Flat Top Belt Conveyor, Industrial Conveyor Belt, Food Conveyor Belt |

Product Detail

| Model No.: | RW-YY-Flush Grid C12 |

|---|---|

| Means of Transport: | Ocean, Air |

| Structure: | Belt Conveyor |

| Material: | Plastic |

| Material Feature: | Heat Resistant |

| Brand Name: | OEM |

| Material: | POM/PE/PP |

| Pitch: | 12mm |

| Thickness:: | 9mm |

| Rod diameter: | 4.6mm |

| cleanability: | easy |

| Surface: | Flat top |

| Open area:: | 26% |

| Belt width:: | Multiples of 25mm |

| Drive system: | Hinge |

| material of small roller: | PE |

| Production Capacity: | 1000 suquer meter/month |

| Packing: | by carton |

| Delivery Date: | 13-18day |

Product Description

Flush Grid plastic modular conveyor belt used in beverage industry

canning convey belt in factory food industry

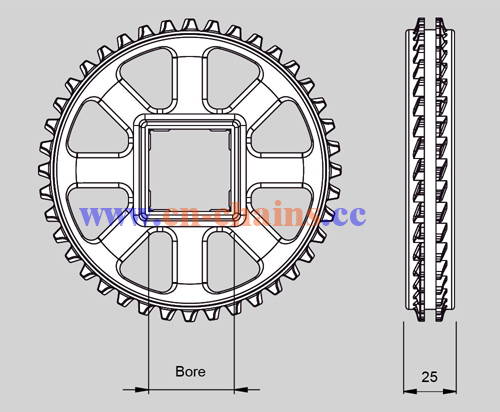

PVC sprockets for conveyor belt

Belt date

Material of the belt | Material of the rod | Belt strength (kg/m) | Temperature range(°C) | Belt weight(kg/㎡ |

PP | PP | 980 | 1 TO 104 | 4.60 |

PE | PE | 550 | -50 to 65 | 4.75 |

POM | PP | 1950 | 1 to 90 | 6.50 |

POM | PE | 1400 | -40 to 65 | 6.54 |

Sprockets data C12

No.of teeth | Diameter pitch | Bore for square shaft |

Hub width | |

mm | in | |||

11 | 42.59 | 20 | 0.75 | 25 |

20 | 76.7 | 40 | 1.5 | 25 |

26 | 99.55 | 40 | 1.5 | 25 |

31 | 118.61 | 40 60 | 1.5 2.5 | 25 |

40 | 152.94 | 40 60 | 1.5 2.5 | 25 |

Series C12 Flush Grid conveyor belt is ideal for product transfers at high speed in small rotation diameters. Its design with the rods in view, together with its

extraordinary open surface, provides a great ease for cleaning.

In the preserved food industry, both fish and vegetables pass through different handling and processing stages in which the belt plays a main role.

We are talking about processes like scalding, boiling, vaporization, pasteurization, etc. The belt structure must allow carrying them out in extreme work

conditions without any alteration of its physical-chemical composition, as it could have an influence on those processes.

Once the product has been canned, the cans handling will be also held on our belts, in machines for closing cans, labelling, weighing, product

accumulation, packing, palletizing, depalletizing, or conveying lines to the storeroom.

Plastic modular conveyor belts,Which comprises two U-shaped bifurcated belt precursor forked belt binding site and the body is provided with bifurcated

pin hole, pin, characterized in that the belt precursor has a matching belt and independent of each other on the gland. Plastic conveyor belt has a long life,

easy maintenance, wear-resistant not afraid of corrosion, the assembly can turn characteristics, and assembled without lubrication, turning flexible,

with good flexibility, can be widely used in electronic , tobacco, chemicals, beverages, food, beer, daily necessities and other industries

POM: That generic polyethylene oxide (abbreviated POM), also known as Race Steel, Special Steel. It is Based on such as formaldehyde as raw material

to aggregate income,POM-H (polyoxymethylene homopolymer), POM-K (polyoxymethylene copolymer) is a thermoplastic plastic high density,

high crystallinity. Has good physical, mechanical and chemical properties, especially those with excellent abrasion performance.

Feature:

1,POM has a very low coefficient of friction and good geometric stability, particularly suitable for the production of gears and bearings

2.High temperature properties,and therefore is also used pipe device (pipe valves,pump housing), lawn equipment, etc

3,Is a tough elastic material, even at low temperatures are still very good creep properties, geometric stability and impact resistance

4,High crystallinity of POM cause it has a high shrinkage rate, reaching a high of 2% to 3.5%. For a variety of enhanced materials have different shrinkage

5.POM is a crystalline plastic, melting point clear, once they reach the melting point, melt viscosity decreased rapidly.

Specific gravity 1.43, melting point

175 ° C, tensile strength (yield) 70MPa, elongation (yield) 15%, (break) of 15%, the impact strength (notched) 108KJ/m2, (band gap) 7.6KJ/m2

Our services

1. Warranty time: 1 year. The conveyor belt / chains / sprockets which supplied by our company could be exchanged when it have quality problems,such as it was broken in installing , the pin run out from chains or the chains parted . But if the user use it in a wrong way, we can not provide any goods for free .

2. Payment: T/T , L/C , Western Union or Paypal .

3. Lead time: 5~15 working days, subject to the order quantity.

4. Shipment: by sea, by air,door to door service for samples transportation.

5. OEM service : we have our own R.D team . If you want to purchase the belt which we have not or you have your own design , we would like to make mold for you for free , only have the condition of requiring continuous orders ,and first order must be more than 60 square meters .

Company and Productsinformationrelated:

Ningbo Rellwin IndustryCo.,ltd.