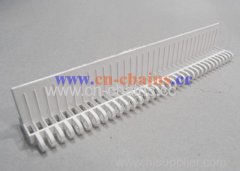

Open drain belt with smooth surface 25-700 flush grid conveyor belts

| Min. Order: | 15 Square Meter |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | T/T, WU |

| Supply Ability: | 1000 suquer meters a mouth |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | Plastic Belt Conveyor, Perforated Flat Top Modular Belt Conveyor, Flat Top Belt Conveyor, Industrial Conveyor Belt, Food Conveyor Belt |

Product Detail

| Model No.: | RW-YY-25-700 |

|---|---|

| Means of Transport: | Ocean, Air |

| Structure: | Belt Conveyor |

| Material: | Plastic |

| Material Feature: | Heat Resistant |

| Brand Name: | OEM |

| Material: | POM/PP |

| Belt surface: | Open belt with a smooth surface |

| Open area: | 27 %. |

| Strength: | An ideal choice for light transportation |

| colour: | White |

| Cleanability: | Good. FSIS |

| Accessories: | 5, 25 and 50 mm flights, 25 and 50 mm side guards. |

| Application: | Vegetables, bakery, seafood, poultry and other industries. Even as cooling/freezing belt |

| Standard widths: | Increments of 6 mm, e.g. 100, 106 mm etc |

| Company type: | Manufacturer |

| Production Capacity: | 1000 suquer meters a mouth |

| Packing: | by carton |

| Delivery Date: | 12-16days |

Product Description

Belt surface: Open belt with a smooth surface..

Open area: 27 %. Biggest opening 3 x 12 mm.

Strength: An ideal choice for light transportation.

Material/colour: PE/nat, PP/white and grey. POM/blue

Cleanability: Good. FSIS

Accessories: 5, 25 and 50 mm flights, 25 and 50 mm side

guards.

Application: Vegetables, bakery, seafood, poultry and other

industries. Even as cooling/freezing belt.

Standard widths: Increments of 6 mm, e.g. 100, 106 mm etc

Heat resistant cleated belt conveyor for conveyor system

sprocket for 25-700 conveyor belt

vulcanizing conveyor belts

plastic modular flight conveyor belt

Flush Grid conveyor belt

| Belt data | ||

| Materials | Max. belt pull kg/m of width | Belt weight kg/m2 |

| Polyethylene (PE) Polypropylene (PP) Polyacetal (POM) | 540 740 1250 | 4 4 6 |

Sprocket Dimensions

No.Teeth | A | B | C |

6 | 59 | 50 | 41 |

12 | 106 | 97 | 88 |

20 | 170 | 161 | 152 |

Payment & Shipping Terms | Supply Capacity | ||

Unit Price: | 70.0~80.0 USD | Production Capacity: | 1000 square meter/month |

Payment Term: | T/T,Western Union | Packing: | carton |

MOQ: | 15square Meter | Delivery Date: | 12-16days |

Means of Transport: | Ocean, Air | ||

Plastic belt is the use of engineering plastics production chain plate assembly made of modular belt with interlocking brickway interleaved mode or by the

total length of the pin assembly together, this design is fundamentally improve the conveyor belt strength.Flights and side panels can also be interlocked

with the hinge pin has become integral parts of the conveyor belt. Plastic belt has too much forms, assembling flexible, easy to replace. There are

openings in the form,

flat, ribs, ball, slip and other forms. Apply to pigs, sheep, chickens, ducks slaughtered , cutting and processing, puffed food production line, fruit grading,

packing lines, fish processing production line, frozen food production line, battery manufacturing, beverage manufacturing, canning industry,

agroindustry,chemical industry , electronics, rubber and plastic manufacturing industry, the cosmetics industry, the general transport operations

"Rellwin Industry Co.,ltd ." with advanced technology, firstclass equipment, specializing in the production of manufacturing; This company produces

modular conveyor belt more than ten years, product aldehyde polymer

polymer materials, such as modular conveyor belt can be resistant to 140 degrees, designed for tyre, supporting enterprises, for cooling, transportation,

its excellent product performance, quality reached the level of import, lower than similar imported4 times, long service life, etc. Material: pom, allow

adequate airflow through, for cooling products. Mode of transmission: hinge transmission matching: driving wheel, abrasive article - its length and width

can be according to the customer.

BENEFITS

-high strength and heavy duty flight design.

-standardisation in conveyor design.

-optimum product stability.

modular conveyor belt Rellwin belts are made of plastic modules. Belts are assembled in an interlocked, bricklayed pattern with full-length hinge

rods – an inherently strong design.

strong and reliable

The 25-700 belt has increased performance in the following industries/applications:

1. Bakery applications including pan handling and incline/decline box or pan applications.

2. Meat or poultry applications including packaging lines and incline box conveyors.

3. Beverage applications including depalletizers, accumulation tables and incline case conveyors.

4. Can manufacturing applications including palletizers, mass handling and accumulation tables.

5. Corrugated applications including downstacker, corrugator take off, transfer car and WIP storage.

6. Tire applications including wigwag, extruder takeaway and inspection applications.

7. Material handling applications including incline applications, palletizers and packaging lines.

We are China modular belt manufacturer offer best modular belt OEM, ODM,service.

Conveyor belt category

All the conveyor belt must be connected in a ring to use, so joint of conveyor belt directly affect the service life of conveyor belt and if conveyor can run

smooth .Generally,conveyor belt connector commonly used method of mechanical joints, cold thermal curing of adhesive joints, joints, etc. Method of

mechanical joints: generally,refers to the use of belt buckle connectors, the connection method is convenient and easy, economical, but the low efficiency

of the joint, easy to damage, has an impact on conveyor belt service life .PVC and PVG solid woven flame retardant antistatic conveyor belt junction, class 8,

with the following products are generally used this method of joints. Conveyor belt cold bonding connection method: using cold bonding adhesive for joints.

This joint approach than a mechanical joint of high efficiency and more economical, connector should be able to have a better result, but in practice, due to

process conditions is difficult to master and adhesive quality very large impact on joints, so it is not very stable.Conveyor belt vulcanizing joints: a proved

to be ideal for a joint approach to ensure high efficiency of the joint, but also very stable, long life joints and easy to grasp. But technical troubles, high

costs, the connection time and other shortcomings.

This belt can be used in canning and candy industry

Canning

In the preserved food industry, both fish and vegetables pass through different handling and processing stages in which the belt plays a main role.

We are talking about processes like scalding, boiling, vaporization, pasteurization, etc. The belt structure must allow carrying them out in extreme work

conditions without any alteration of its physical-chemical composition, as it could have an influence on those processes.

Once the product has been canned, the cans handling will be also held on our belts, in machines for closing cans, labelling, weighing, product

accumulation, packing, palletizing, depalletizing, or conveying lines to the storeroom.

Candy

Conveyance in sweets industry has problems due to the sticky surface of most of the products involved. Rellwin has belt types with special surfaces in

order to minimize the adherence between product and belt.

Big gooseneck elevating conveyors which feed the weighing-bagging machines should always use modular belts in order to avoid a continuous

maintenance of plastic scoops and heavy transmission chains, as well as the productivity loss.

The Flush Grid belts are ideal for cooling these products thanks to their open surface which enables air and

refrigerating liquids to pass through it, as well as it makes the cleaning easier.

Our services

1. Warranty time: 1 year. The conveyor belt / chains / sprockets which supplied by our company could be exchanged when it have quality problems,such as it was broken in installing , the pin run out from chains or the chains parted . But if the user use it in a wrong way, we can not provide any goods for free .

2. Payment: T/T , L/C , Western Union or Paypal .

3. Lead time: 5~15 working days, subject to the order quantity.

4. Shipment: by sea, by air,door to door service for samples transportation.

5. OEM service : we have our own R.D team . If you want to purchase the belt which we have not or you have your own design , we would like to make mold for you for free , only have the condition of requiring continuous orders ,and first order must be more than 60 square meters .

Company and Productsinformationrelated:

Ningbo Rellwin IndustryCo.,ltd