Modular Plastic conveyor belt 2400 for transmission equipment in industry

| Min. Order: | 10 Square Meter |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | T/T, WU |

| Supply Ability: | 1000 suquer meters a mouth |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | Plastic Belt Conveyor, Perforated Flat Top Modular Belt Conveyor, Flat Top Belt Conveyor, Industrial Conveyor Belt, Food Conveyor Belt |

Product Detail

| Model No.: | RW-YY-2400 |

|---|---|

| Means of Transport: | Ocean, Air |

| Structure: | Belt Conveyor |

| Material: | Plastic |

| Material Feature: | Heat Resistant |

| Brand Name: | OEM |

| Material: | POM / PP/PE |

| Pitch: | 46mm |

| Minimum Width: | 195mm |

| Open Area: | 52% |

| Weight:: | 6KG/Square meter |

| Backflex radius(min):: | 76mm |

| Side Guard: | No |

| Color: | Gray and so on |

| Application: | manufacturing |

| Export Markets: | North America, South America, Eastern Europe, Southeast Asia, Oceania, Mid East, Western Europe |

| Production Capacity: | 1000 suquer meters a mouth |

| Packing: | by carton |

| Delivery Date: | 13-18days |

Product Description

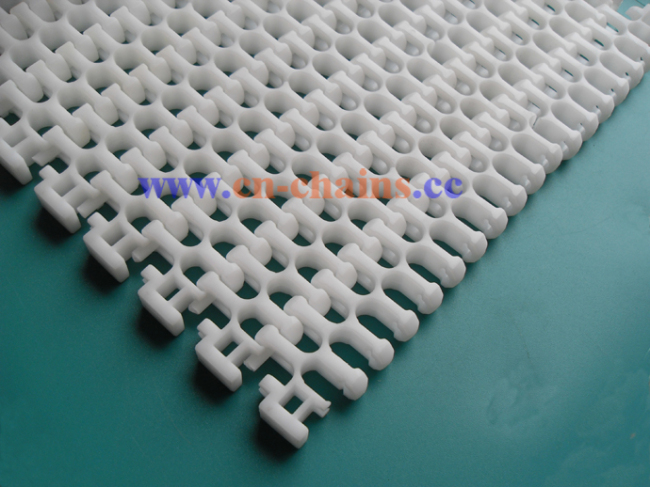

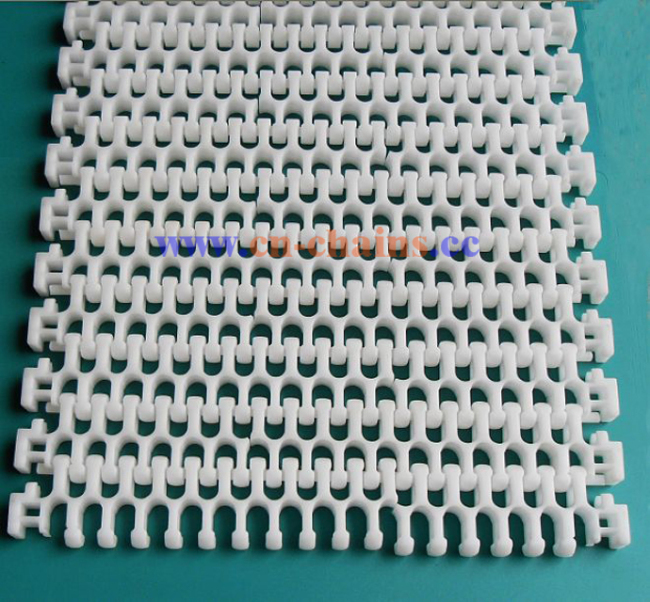

Flush Grid Radius CONVEYOR BELT for transport line

Radius belting 2400 China belt industry

Flush Grid Plastic modular conveyor belt

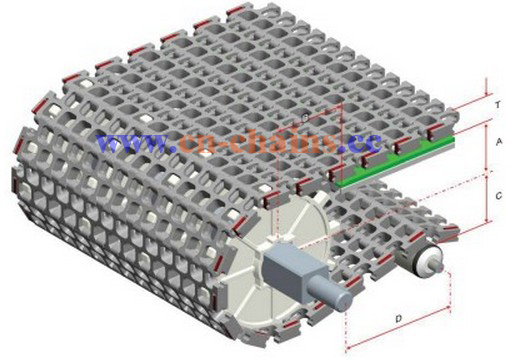

Sprockets data

Type | Teeth | Pitch Diameter | Outside diameter | Bore(mm)

| |||

mm | inch | mm | inch | mm | inch | ||

2400A-8T |

8 |

120.20 |

4.73 |

120 |

4.72 | 40 | 1.57 |

2400A-12T | 12 | 177.73 | 6.70 | 185 | 7.28 | 40 | 1.57 |

| Belt Material | Belt Strength K g /M (B W ) | Temperature | Belt Weight | ||||

| Straight | Curve | ℃ (min.) | ℃ (max.) | (K g /M 2) | |||

| Kg/M(BW) | N/M(BW) | Kg/M(BW) | N/M(BW) | ||||

| Polypropylene | 1870 | 18700 | 142 | 1420 | 1 | 100 | 6 |

| Polyethylene | 1330 | 13300 | 82 | 820 | -60 | 60 | 6.8 |

| Acetal | 2900 | 29000 | 142 | 1420 | -40 | 80 | 8.7 |

| Nylon | 1870 | 18700 | 82 | 820 | 1 | 180 | 8.6 |

| BW – Belt Width | |||||||

Payment & Shipping Terms | Supply Capacity | ||

Unit Price: | 45.0~95.0 USD | Production Capacity: | 1000 square meter/month |

Payment Term: | T/T,Western Union | Packing: | carton |

MOQ: | 10 square Meter | Delivery Date: | 13-18days |

Means of Transport: | Ocean, Air | ||

2400 plastic radius conveyor belt material: POM,PP (polypropylene), PE (polyethylene), ACETAL (ACETAL), NYLON (NYLON), and other materials.(some belt type conforms to the

FDA, the USDA standards, so it is widely used in tire industry.)

Structure are: straight and level transport, lifting /, transportation, and other forms of turning, conveyor belt can also add lifting, side panel, such as

accessories, can meet various requirements in the form of transport.Features: use plastic material which is conform to the hygiene standards, there is no

wool stoma and aperture structure.Regardless of any product.Will not be entrained by product oil pollution by osmosis.Not any impurities on the conveyor

Belt surface adsorption.So can be one of the most secure of the manufacturing process.In addition, its stability and chemical resistance is strong, will

not damage by cleaner or high temperature water.

Plastic belt is the use of engineering plastics production chain plate assembly made of modular belt with interlocking brickway interleaved mode or by

the total length of the pin assembly together, this design is fundamentally improve the conveyor belt strength.Flights and side panels can also be

interlocked with the hinge pin has become integral parts of the conveyor belt. Plastic belt has too much forms, assembling flexible, easy to replace. There

are openings in the form, flat, ribs, ball, slip and other forms. Apply to pigs, sheep, chickens, ducks slaughtered , cutting and processing, puffed food

production line, fruit grading,packing lines, fish processing production line, frozen food production line, battery manufacturing, beverage manufacturing,

canning industry, agroindustry,chemical industry , electronics, rubber and plastic manufacturing industry, the cosmetics industry, the general transport

operations

Advantage

Precision molding process ensures optimum flatness.

High wear resistance and low friction coefficient

High work load

Why choose the modualr chains?

Modular conveyor chain in an interlocking manner or bricklaying way intertwined by the total length of the pin assembly together, this design improves the

strength of the chain fundamentally. (Rellwin) has extensive experience in the design and application of modular chain fields.

Introduce the specific advantages modular conveyor chain has,compared to other ,in brief sentence.

Rellwin modular conveyor chain bring more valuable solutions than ordinary chains

What are the benefits can the modular bring you?

·By extending the life of the conveyor chain (from a few weeks or a few months to several years extended), significantly reducing the cost of replacement

of the chain

·Save maintenance time and costs: modular design lets you do not need to remove the entire chain to replace the damaged section

·Eliminate deviation and associated costs: drive sprocket tooth forced deviation phenomenon does not occur

·The risk associated with the bond reduced 80% cut-off

·Eliminate all costs associated with the conveyor chain vulcanization, stitching, bonding and surface inspection-related

·Reduce the slope of the yield loss transfer applications: Intralox chain so you can build conveyor Z-shaped configuration, thus

eliminating the delivery point will cause product damage, while saving space and reducing the number of drive motors required

·Reduce the risk of contamination due to damage caused by the chain

Rellwin modular conveyor chain bring more valuable solutions than metallic chains.

What are the benefits can the modular bring you?

·By extending the life of the conveyor chain (from a few weeks or a few months to several years extended), significantly reducing the cost of replacement

of the chain

·Save maintenance time and costs: modular design lets you do not need to remove the entire chain to replace the damaged section

·Reduce the risk of contamination due to damage caused by the chain

Our services

1. Warranty time: 1 year. The conveyor belt / chains / sprockets which supplied by our company could be exchanged when it have quality problems,such as it was broken in installing , the pin run out from chains or the chains parted . But if the user use it in a wrong way, we can not provide any goods for free .

2. Payment: T/T , L/C , Western Union or Paypal .

3. Lead time: 5~15 working days, subject to the order quantity.

4. Shipment: by sea, by air,door to door service for samples transportation.

5. OEM service : we have our own R.D team . If you want to purchase the belt which we have not or you have your own design , we would like to make mold for you for free , only have the condition of requiring continuous orders ,and first order must be more than 60 square meters .

Company and Productsinformationrelated:

Ningbo Rellwin IndustryCo.,ltd